906141

SAFETY PRECAUTIONS

Always disconnect power to the dispenser before servicing or cleaning.

Never place hands inside of hopper or gate area without disconnecting power to the dispenser. Agitator rotation

occurs automatically when the dispenser is energized!

This ice dispenser has been specifically designed to provide protection against personal injury and eliminates

contamination of ice. To insure continued protection and sanitation, observe the following

ALWAYS be sure the removable lid is properly installed to prevent

unauthorized access to the hopper interior and possible contamination of ice.

ALWAYS be sure the upper and lower front panels are securely fastened.

ALWAYS keep area around the dispenser clean of ice cubes.

CAUTION: Dispenser cannot be used with crushed or flaked ice.

Use of bagged ice which has frozen into large chunks can void warranty. The dispenser

agitator is not designed to be an ice crusher. Use of large chunks of ice which “jam up”

inside the hopper will cause failure of the agitator motor and damage to the hopper. If bagged ice

is used, it must be carefully and completely broken into small, cube-sized pieces before filling into

the dispenser hopper.

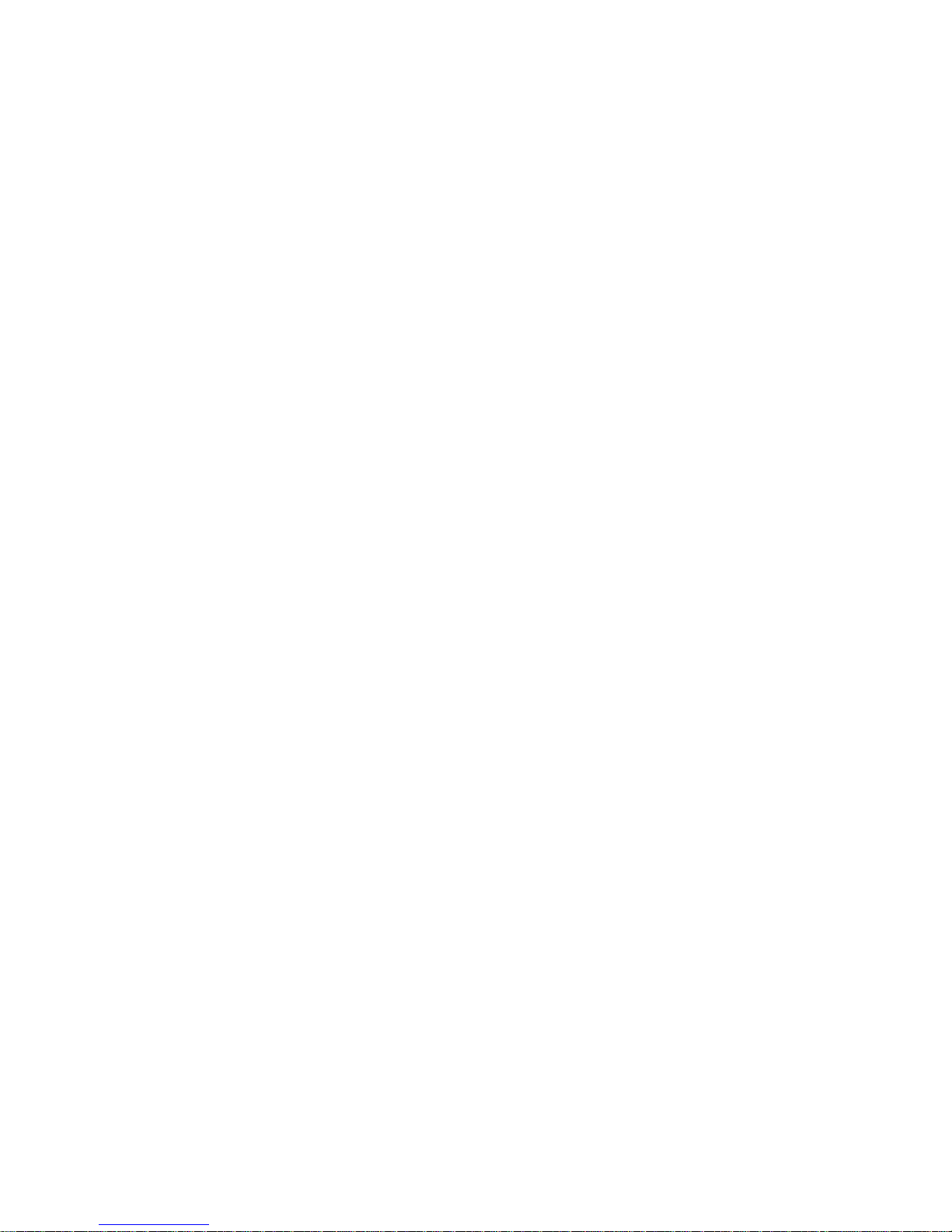

GENERAL DESCRIPTION

The Remcor “TJ”series of ice dispensers will solve ice and beverage service needs in the sanitary, space

saving, economical way. Designed to be manually filled with ice from any remote ice making source, these

dispensers will dispense cubes (up 1”in size), cubelets, hard-chipped or cracked ice.

Table 1. Specifications

Model: TJ45

Ice Storage Capacity: 45 lbs.

Electrical: 120/1/60 3AMP

Drain Connection: 3/4” F.P.T.

Electrical Connection: 6’, 3-wire cord with 3-prong ground-type plug

Dimensions: 26½”H x 16”W x 22”D

Model: TJ90

Ice Storage Capacity: 90 lbs.

Electrical: 120/1/60 3AMP

Drain Connection: 3/4” F.P.T.

Electrical Connection: 6’, 3-wire cord with 3-prong ground-type plug

Dimensions: 30”H x 22”W x 28”D