It is evident that the corrosion

rate below 50 % relative humidity

(RH) is low, and below 40 % is

negligible.

The corrosion rate increases

significantly above 60% RH.

This threshold for damage as the

result of humidity also applies to

other materials, such as powdery

substances, packaging, wood and

electronic units.

Buildings may be dried in a variety

of ways:

1. By heating and air exchange:

The air in the room is heated

in order for moisture to be

removed and then this air is fed

outside. All of the energy that

is involved is lost together with

the moist air that is released.

2. By air dehumidification:

The moist air that is present

within an enclosed space is

continuously dehumidified

according to the condensation

principle.

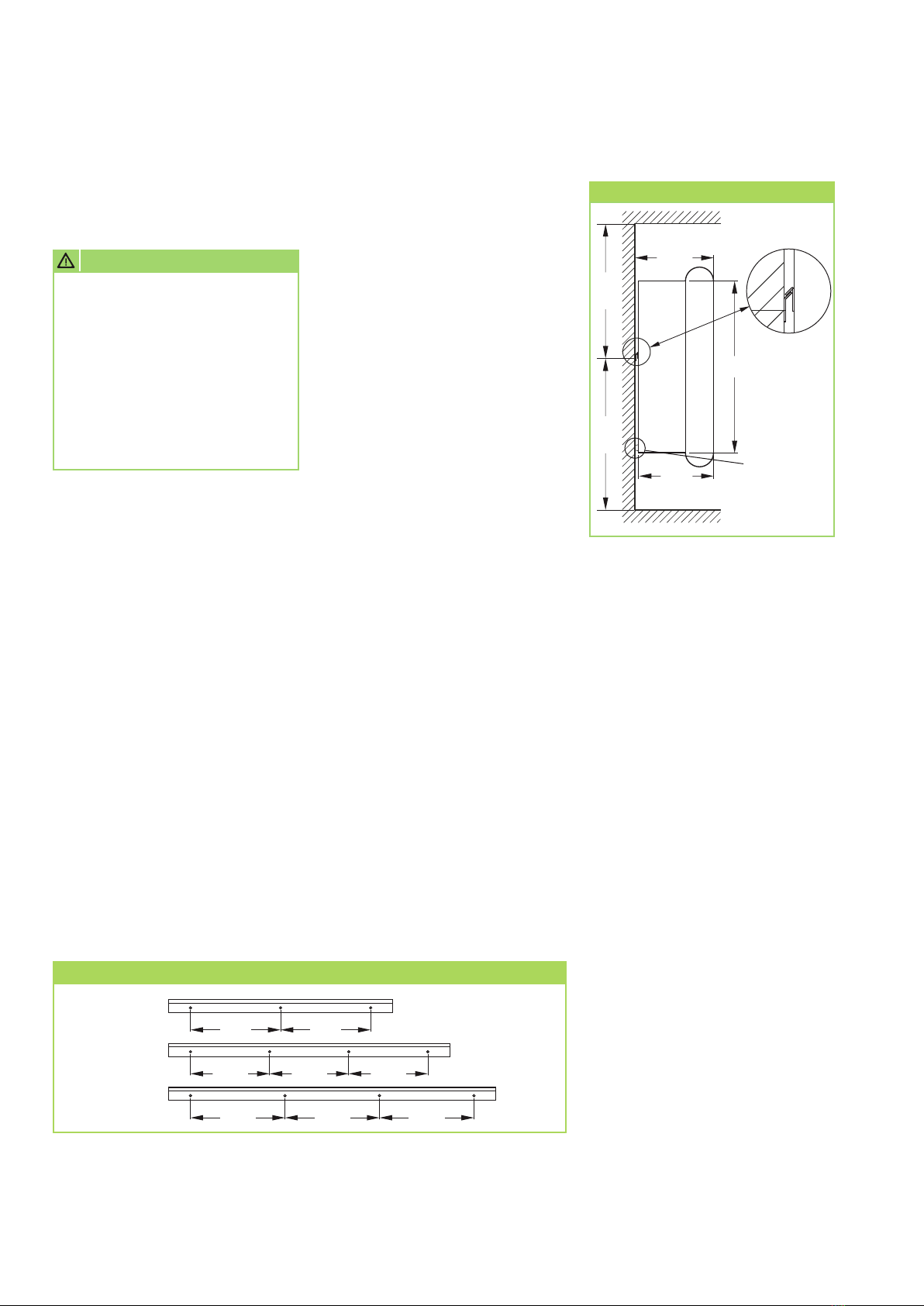

The correlations occurring when

air is dehumidified are based on

physical laws.

These are depicted here in

graphical form in order to provide

you with a brief overview of the

principles of air dehumidification.

The use of

REMKO air dehumidifiers

– Even if windows and doors

are well insulated, water and

moisture are still capable of

penetrating thick concrete walls.

– The water required for setting

in the production of concrete,

mortar and plaster etc. may only

be diffused after 1-2 months.

– Even moisture trapped in the

masonry after high-water or

a flood is released very slowly.

– The same is also true of

moisture contained in stored

materials for example.

The moisture (water vapour)

released from parts of a building

or materials is absorbed by the

surrounding air. As a result, the

moisture content increases, which

ultimately gives rise to corrosion,

mould, rot, peeling of paint and

other unwanted damage.

By way of example, the diagram

shows the corrosion rate of metal

in different levels of humidity.

Air dehumidification

Relative humidity %

Corrosion rate

With regard to energy

consumption, air dehumidification

has one distinct advantage:

Energy expenditure is limited

exclusively to the air volumes

present. The mechanical heat that

is released by the dehumidification

process is fed back into the room.

Under normal use, the

air

dehumidifier

uses approximately

25 % of the energy that is

required for the

“heating and

ventilating” principle.

Relative air humidity

Our ambient air is a gaseous

mixture which always contains

a certain volume of water in the

form of water vapour. This volume

of water is specified in g per kg of

dry air (absolute moisture content).

1 m3of air weighs approx. 1.2 kg

at 20 °C

Depending on the temperature,

each kg of air is only capable of

absorbing a certain volume of

water vapour. Once this capacity

has been reached, the air is

referred to as “saturated” and has

a relative humidity (RH) of 100 %.

Relative humidity is understood

to mean the ratio between the

current quantity of water vapour in

the air and the maximum possible

quantity of water vapour at the

same temperature.

The ability of the air to absorb

water vapour increases as

the temperature rises. I.e. the

maximum possible (absolute)

water content becomes greater as

the temperature rises.

5