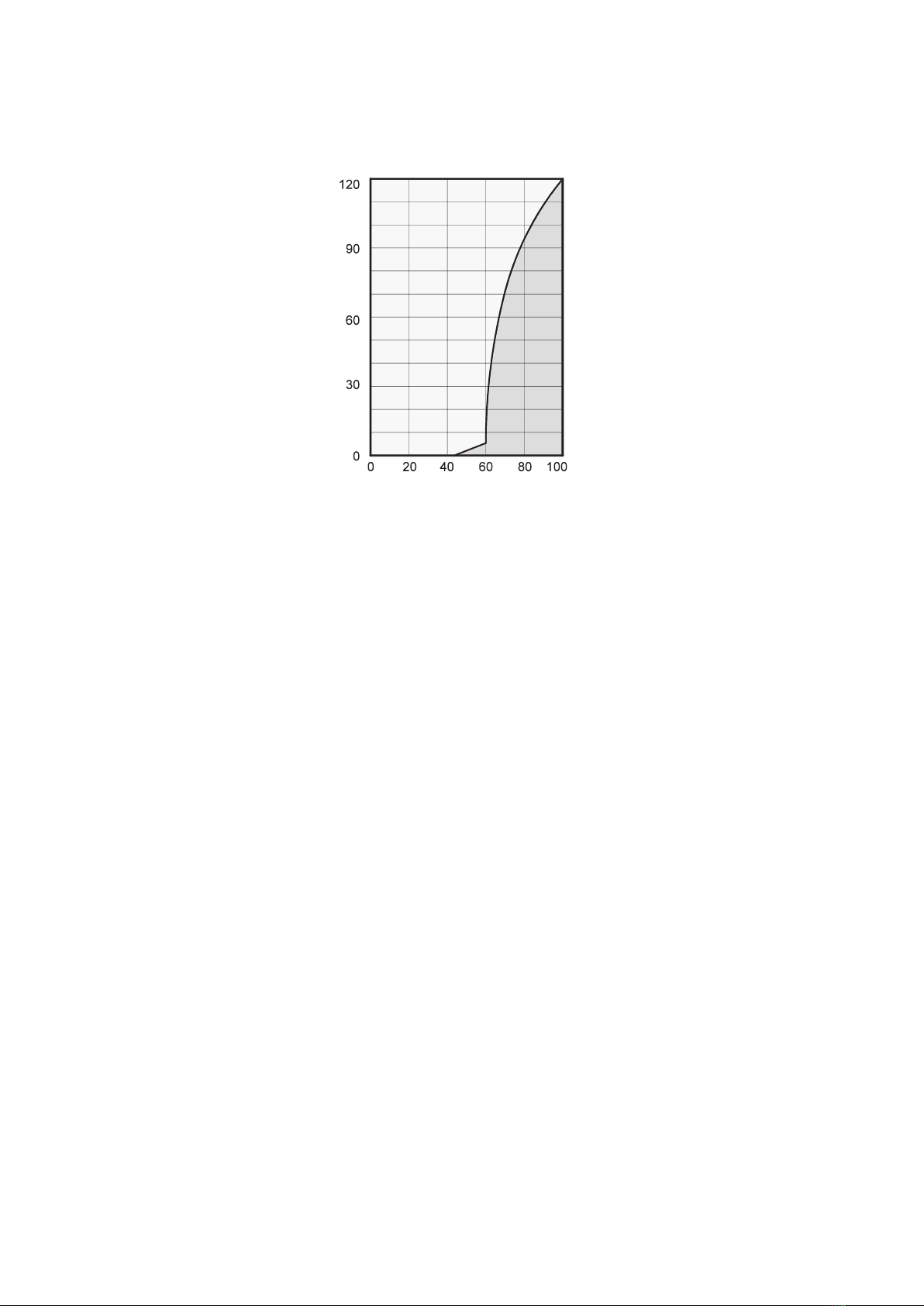

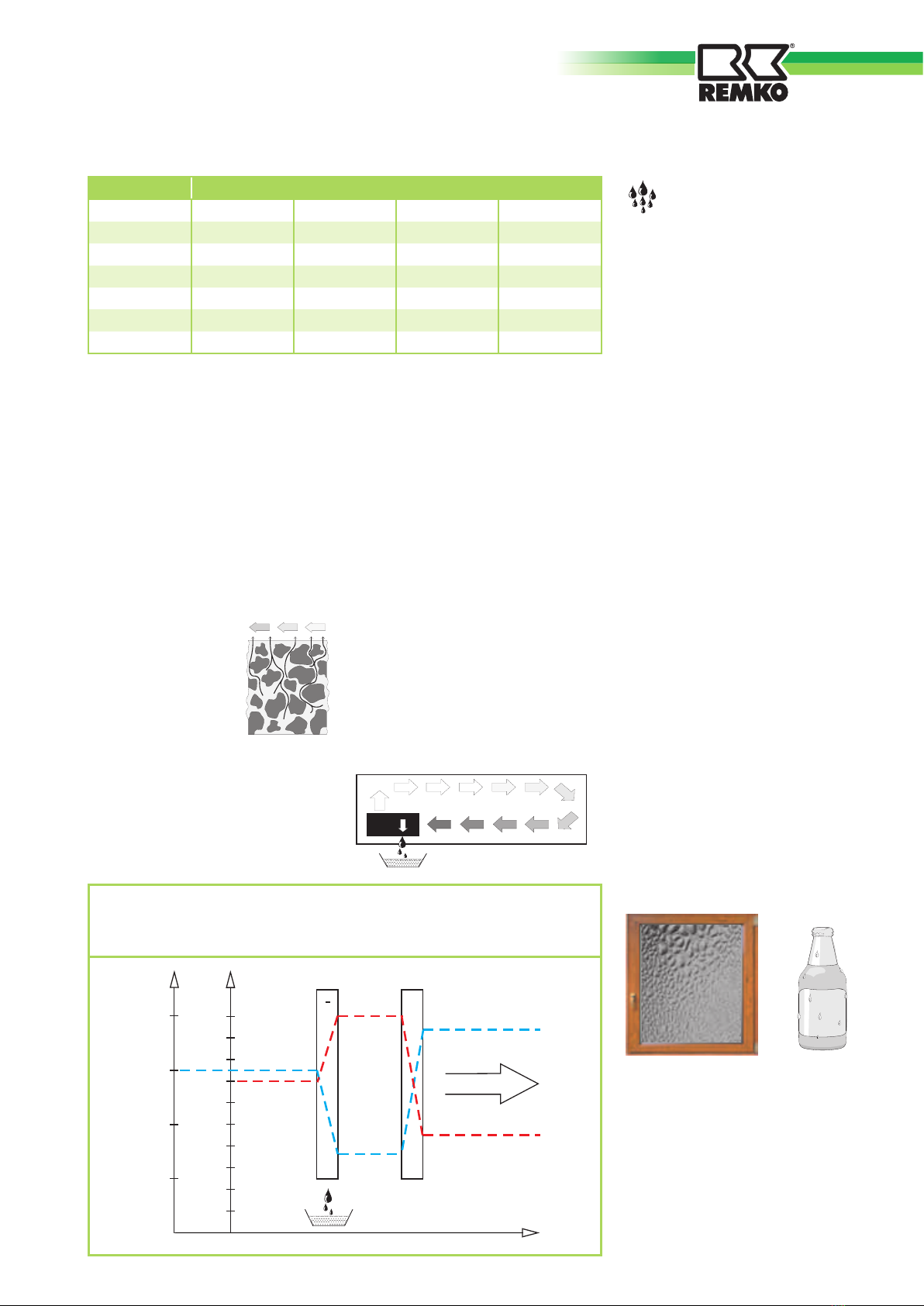

It is noticeable that the rate of

corrosion is insignificant below

50% relative humidity and can be

disregarded below 40% relative

humidity.

The rate of corrosion increases

noticeably from 60% relative

humidity. This humidity damage

limit applies also to numerous

other materials, e.g. powders,

packaging, wood or electronic

equipment.

Buildings can be dried out in

different ways:

1. Heating and air exchange:

The room air is heated to absorb

moisture to subsequently be

discharged to the atmosphere.

The total input energy is lost

with the discharged, moist air.

2. Dehumidification:

The moist air in an enclosed

room is continuously

dehumidified according to the

condensation principle.

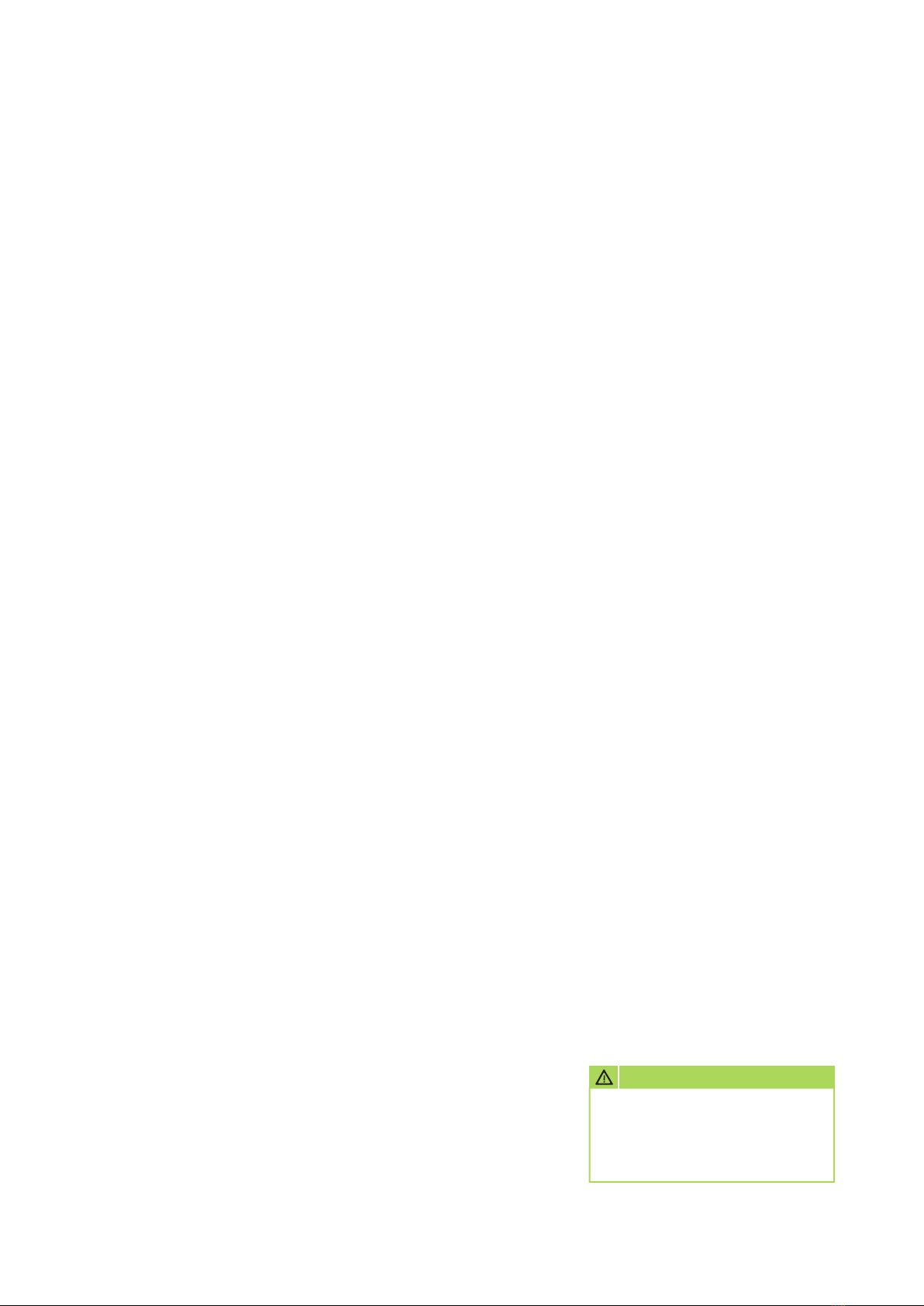

The interrelated processes

occurring during dehumidification

are based on physical laws.

These are illustrated here in

simplified form in order to explain

the principle of dehumidification.

The use of REMKO

dehumidifiers

– No matter how well windows

and doors are insulated, damp

and moisture can penetrate

even through thick concrete

walls.

– The water volumes required

for binding concrete, mortar,

plaster, etc. are diffused out

initially after 1-2 months under

certain circumstances.

– Even moisture that has

penetrated masonry following

high water or flooding is

released very slowly.

– This applies similarly to e.g.

moisture contained in stored

materials.

The moisture (water vapour)

escaping from buildings or

materials is absorbed by the

ambient air. This increases their

moisture content and ultimately

results in corrosion, mould, rot,

peeling of paint coatings and other

unwanted moisture damage.

The diagram opposite shows an

example of the rate of corrosion,

e.g. for metal at different humidity

levels.

Dehumidification

In terms of energy consumption,

dehumidification has one decisive

advantage:

Energy expenditure is restricted

solely to the existing room volume.

The mechanical heat released

through the dehumidification

process is returned to the room.

With correct use, the dehumidifier

consumes only about 25% of the

energy required for the “heating

and ventilation” principle.

Relative humidity

Ambient air is a gas mixture

and always contains a certain

amount of water in the form of

water vapour. This water volume

is expressed in g per kg dry air

(absolute water content).

1m3air weighs about 1.2 kg at

20°C

Depending on the temperature,

each kg of air is only able to

absorb a certain amount of water

vapour. When this absorptive

capacity is reached, reference is

made to “saturated” air; this has a

relative humidity of 100%.

Relative humidity is therefore

understood to be the ratio

between the amount of water

vapour currently contained in

the air and the maximum water

vapour volume at the same

temperature.

The ability of air to absorb water

vapour increases with increasing

temperature. This means that

the maximum (= absolute) water

content increases with increasing

temperature.

Rate of corrosion

Rel. humidity in %

4

REMKO SLE 20