ELECTRIC DUCT HEATER

RENEWAIRE.COM INSTALLATION, OPERATION AND MAINTENANCE MANUAL 1.800.627.4499

10

INSTALLATION INSTRUCTIONS

INSTALLATION

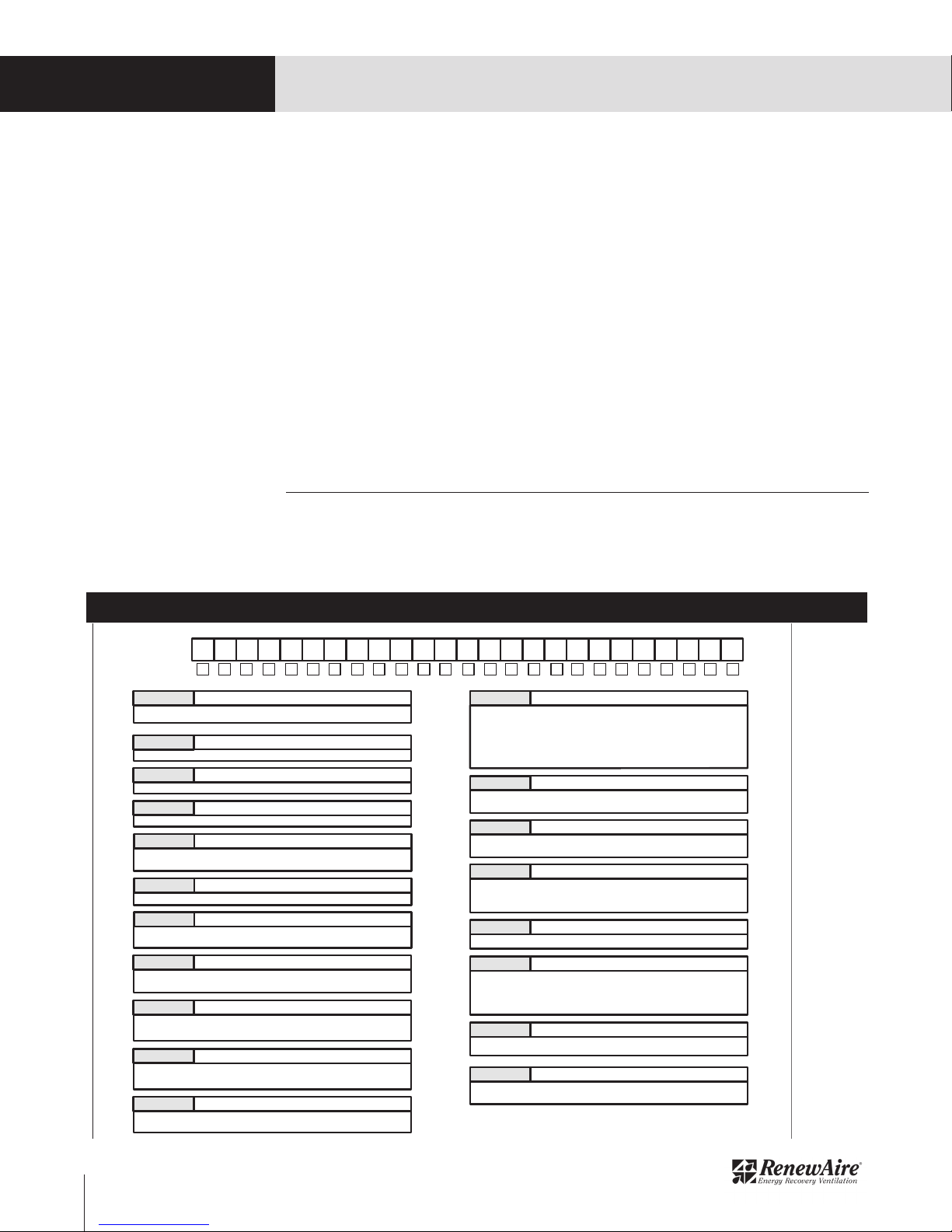

F1 Slip-In Heater F2 Flange Heater

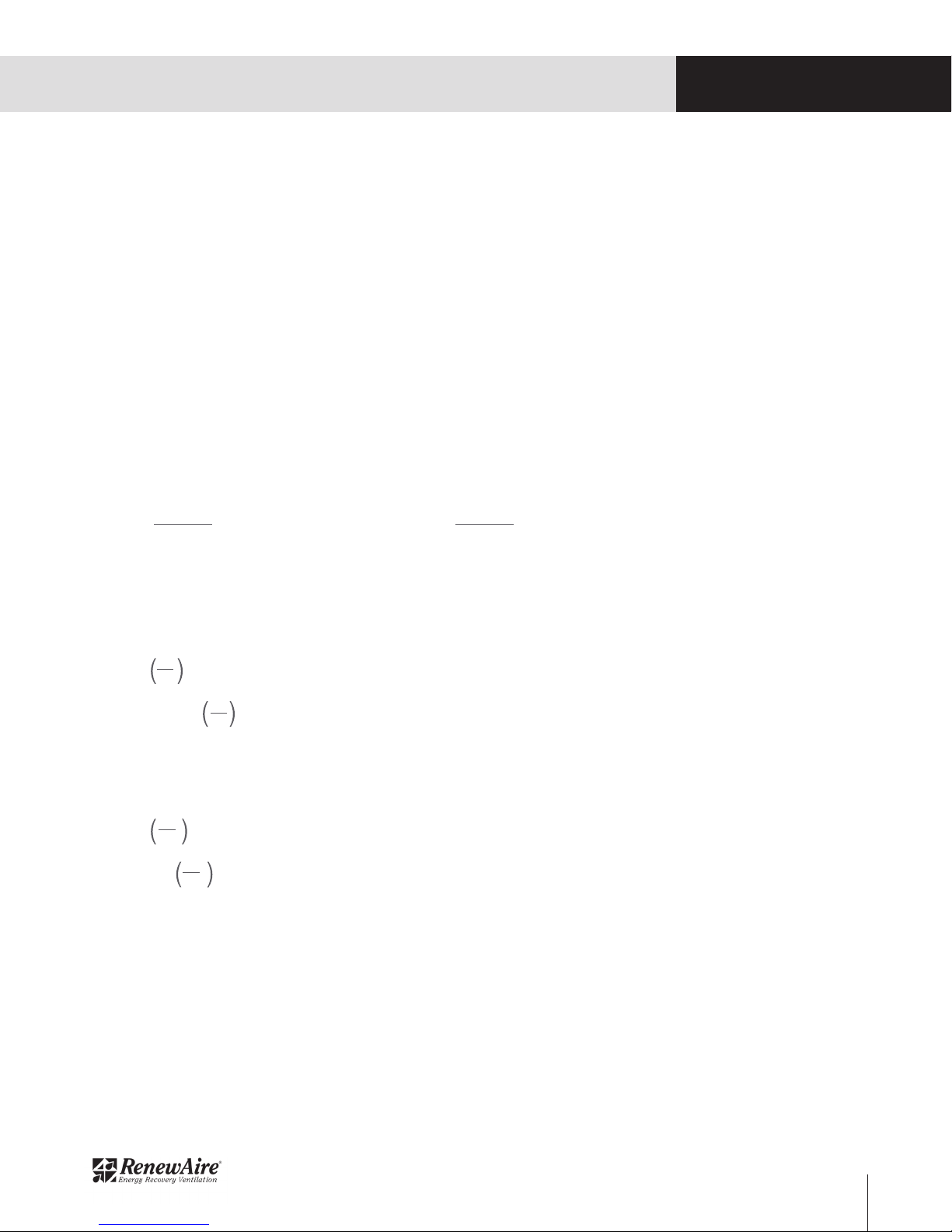

See Figure F3 for examples of some common installation approaches (flippable EK series only).

F3 Common Installation Approaches

To install a slip-in heater Figure F1, cut an opening, as required in the side of the duct. Slide heater in

the duct using control box as template to mark the mounting screw holes. Remove unit and drill mounting

holes. Mount unit to duct with sheet metal screws. Connect high and low voltage supplies along with fan

interlock circuit (if no airflow switch is furnished). Larger heaters may require hangers.

To install a flange type heater Figure F2, insert heater between two sections of flanged duct and bolt in

place. For additional strength, the duct flange should be doubled as shown in the figure. Large heaters

may require hanger straps. Connect high and low voltage supplies along with fan interlock circuit (if no

airflow switch is furnished).

ELECTRICAL REQUIREMENTS

Refer to general wiring diagram on pages 13-14. Each heater also has its specific wiring schematic label

on the inside cover of the heater control box.

WRAPPER

SLIP-IN

CONSTRUCTION

SHOWN

AIR DUCT

BASE

HEATER

BASE HEATER

ROTATED 180

BASE

HEATER

BASE HEATER

FLIPPED 180°

* ONE HEATER- 4

POSITIONS

HORIZONTAL DUCT & AIRFLOW

with HORIZONTAL INSTALLATION

AIRFLOW

AIRFLOW

VERTICAL DUCT & AIRFLOW

AIRFLOW

AIRFLOW

* SAME HEATER- FOR

VERTICAL DUCTS

VERTICAL DUCT & AIRFLOW

* SAME HEATER -

FOR VERTICAL DUCTS

* ONE HEATER -

4 POSITIONS

HORIZONTAL DUCT & AIRFLOW

WITH HORIZONTAL INSTALLATION

S L I P - O N

CONSTRUCTION

SHOWN

AIR DUCT

B A S E

HEATER

B A S E

HEATER

BA S E HE AT E R

ROTATED 180°

BA S E HE AT E R

FLIPPED 180°

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

'W'

'H'

06-4141-00 REV. C E.C.O. 10438

INSTALLATION MANUAL

TUTCO DUCT HEATERS

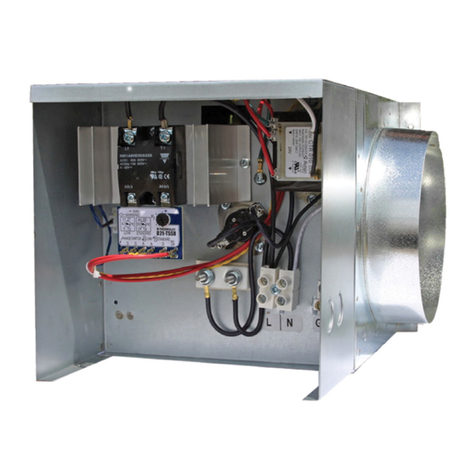

The information and instructions in this sheet apply to Duct Heater

models for zero clearance installation in ducts.

The Duct Heaters are approved for use with heat pumps, air

conditioners, or other forced air systems. They may be controlled by

contactors, relays, sequencers or solid state devices.

The Duct Heaters are prewired, have voltage ratings to 600 volts, both

single phase and three phase.

The Duct Heaters are furnished with integral controls, except for the DD

& DHD series, which are furnished with a separate control panel for

remote mounting.

GENERAL:

Inspect heater for any possible shipping damage. Check all insulators

for breakage and inspect heater element wire for any deformation that

could cause a short circuit or ground. Make sure all fasteners are tight.

Electrical connections such as pressure terminals should be checked for

tightness.

INSTALLATION:

For safe operation and best performance, the following installation

procedures must be adhered to.

Heaters may be installed in the sides of either horizontal or vertical

ducts but never in the top or bottom of a horizontal duct. Heaters

installed in vertical ducts are tested and approved for up airflow only!

1.Install a heater a minimum of (4) feet from heat pumps or central air

conditioners.

2. At least 4 feet downstream from an air handler.

3. At least 2 feet either side of an elbow or turn.

4. At least 4 feet from any canvas duct connector or transition section for

change in duct size.

5. At least 4 feet downstream from an air filter.

6. At least 4 feet upstream from a humidifier.

Refer to the back of this sheet for: duct, electrical and air velocity

requirements.

To install a slip-in heater FIG.1, cut an opening, as required in the side

of the duct. Slide heater in the duct using control box as template to

mark the mounting screw holes. Remove unit and drill mounting holes.

Mount unit to duct with sheet metal screws. Connect high and low

voltage supplies along with fan interlock circuit (if no airflow switch is

furnished). Larger heaters may require hangers.

To install a flange type heater FIG.2, Insert heater between two sections

of flanged duct and bolt in place. For additional strength, the duct flange

should be doubled as shown in the figure. Large heaters may require

hanger straps. Connect high and low voltage supplies along with fan

interlock circuit (if no airflow switch is furnished).

500 GOULD DRIVE COOKEVILLE, TN 38506

FAX (931)432-4140 PHONE (931)432-4141

INC.

06-4141-00 REV. C E.C.O. 10438

INSTALLATION MANUAL

TUTCO DUCT HEATERS

The information and instructions in this sheet apply to Duct Heater

models for zero clearance installation in ducts.

The Duct Heaters are approved for use with heat pumps, air

conditioners, or other forced air systems. They may be controlled by

contactors, relays, sequencers or solid state devices.

The Duct Heaters are prewired, have voltage ratings to 600 volts, both

single phase and three phase.

The Duct Heaters are furnished with integral controls, except for the DD

& DHD series, which are furnished with a separate control panel for

remote mounting.

GENERAL:

Inspect heater for any possible shipping damage. Check all insulators

for breakage and inspect heater element wire for any deformation that

could cause a short circuit or ground. Make sure all fasteners are tight.

Electrical connections such as pressure terminals should be checked for

tightness.

INSTALLATION:

For safe operation and best performance, the following installation

procedures must be adhered to.

Heaters may be installed in the sides of either horizontal or vertical

ducts but never in the top or bottom of a horizontal duct. Heaters

installed in vertical ducts are tested and approved for up airflow only!

1.Install a heater a minimum of (4) feet from heat pumps or central air

conditioners.

2. At least 4 feet downstream from an air handler.

3. At least 2 feet either side of an elbow or turn.

4. At least 4 feet from any canvas duct connector or transition section for

change in duct size.

5. At least 4 feet downstream from an air filter.

6. At least 4 feet upstream from a humidifier.

Refer to the back of this sheet for: duct, electrical and air velocity

requirements.

To install a slip-in heater FIG.1, cut an opening, as required in the side

of the duct. Slide heater in the duct using control box as template to

mark the mounting screw holes. Remove unit and drill mounting holes.

Mount unit to duct with sheet metal screws. Connect high and low

voltage supplies along with fan interlock circuit (if no airflow switch is

furnished). Larger heaters may require hangers.

To install a flange type heater FIG.2, Insert heater between two sections

of flanged duct and bolt in place. For additional strength, the duct flange

should be doubled as shown in the figure. Large heaters may require

hanger straps. Connect high and low voltage supplies along with fan

interlock circuit (if no airflow switch is furnished).

500 GOULD DRIVE COOKEVILLE, TN 38506

FAX (931)432-4140 PHONE (931)432-4141

INC.

06-4141-00 REV. C E.C.O. 10438

INSTALLATION MANUAL

TUTCO DUCT HEATERS

The information and instructions in this sheet apply to Duct Heater

models for zero clearance installation in ducts.

The Duct Heaters are approved for use with heat pumps, air

conditioners, or other forced air systems. They may be controlled by

contactors, relays, sequencers or solid state devices.

The Duct Heaters are prewired, have voltage ratings to 600 volts, both

single phase and three phase.

The Duct Heaters are furnished with integral controls, except for the DD

& DHD series, which are furnished with a separate control panel for

remote mounting.

GENERAL:

Inspect heater for any possible shipping damage. Check all insulators

for breakage and inspect heater element wire for any deformation that

could cause a short circuit or ground. Make sure all fasteners are tight.

Electrical connections such as pressure terminals should be checked for

tightness.

INSTALLATION:

For safe operation and best performance, the following installation

procedures must be adhered to.

Heaters may be installed in the sides of either horizontal or vertical

ducts but never in the top or bottom of a horizontal duct. Heaters

installed in vertical ducts are tested and approved for up airflow only!

1.Install a heater a minimum of (4) feet from heat pumps or central air

conditioners.

2. At least 4 feet downstream from an air handler.

3. At least 2 feet either side of an elbow or turn.

4. At least 4 feet from any canvas duct connector or transition section for

change in duct size.

5. At least 4 feet downstream from an air filter.

6. At least 4 feet upstream from a humidifier.

Refer to the back of this sheet for: duct, electrical and air velocity

requirements.

To install a slip-in heater FIG.1, cut an opening, as required in the side

of the duct. Slide heater in the duct using control box as template to

mark the mounting screw holes. Remove unit and drill mounting holes.

Mount unit to duct with sheet metal screws. Connect high and low

voltage supplies along with fan interlock circuit (if no airflow switch is

furnished). Larger heaters may require hangers.

To install a flange type heater FIG.2, Insert heater between two sections

of flanged duct and bolt in place. For additional strength, the duct flange

should be doubled as shown in the figure. Large heaters may require

hanger straps. Connect high and low voltage supplies along with fan

interlock circuit (if no airflow switch is furnished).

500 GOULD DRIVE COOKEVILLE, TN 38506

FAX (931)432-4140 PHONE (931)432-4141

INC.

TERMINAL OR

CONTROL BOX

HEATING

ELEMENTS

FRAME

FRAME

TERMINAL OR

CONTROL BOX

HEATING

ELEMENTS