RH-D AND RH-W ELECTRIC DUCT HEATERS

RENEWAIRE.COM INSTALLATION, OPERATION AND MAINTENANCE MANUAL 1.800.627.44994

OWNER INFORMATION

TABLE OF CONTENTS

TABLE OF ILLUSTRATIONS

IMPORTANT SAFETY INFORMATION 2

UNIT RECORDS 3

1.0 OVERVIEW 5

1.1 DESCRIPTION 5

1.2 APPLICATIONS 5

1.3 SAFETY FEATURES 5

1.3.1 Low Air Flow Modulation / Shut Off 5

1.3.2 Auto-Reset Thermal Cutout 5

1.3.3 Manual Reset Thermal Cutout 5

1.3.4 Maintenance 5

1.4 AIRFLOW DIRECTION 5

1.4.1 RH-D 5

1.4.2 RH-W 5

1.5 RH-D AND RH-W MODELS 6

2.0 COMPONENT DESCRIPTION 7

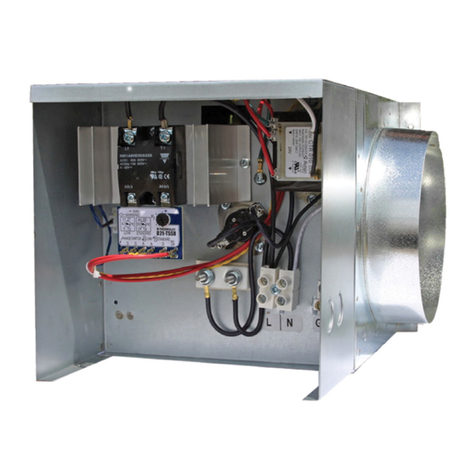

2.1 RH-D 7

2.2 RH-W 8

2.2.1 CTH291 Thermostat 8

2.3 COMPANION ACCESSORIES 9

2.3.1 Occupancy Sensor 9

2.3.2 Timer 9

3.0 DIMENSIONED DRAWINGS 10

3.1 RH-D AND RH-W WITH 6” DUCT COLLAR 10

3.2 RH-D AND RH-W WITH 8” DUCT COLLAR 10

3.3 RH-D AND RH-W WITH 10” DUCT COLLAR 11

3.4 RH-D AND RH-W WITH 12” DUCT COLLAR 11

4.0 UNIT WEIGHTS 12

4.1 RH-D AND RH-W WITH 6” DUCT 12

4.2 RH-D AND RH-W WITH 8” DUCT 12

4.3 RH-D AND RH-W WITH 10” OR 12” DUCTS 12

5.0 INSTALLATION 12

5.1 MINIMUM AIRFLOW REQUIREMENTS 12

5.2 INSTALLATION LOCATION 12

5.3 UNIT ORIENTATION 12

5.4 INSTALLATION CLEARANCES 12

5.5 DUCTWORK CONNECTIONS 12

5.6 DUCTWORK INSULATION 13

5.7 VERIFY AIRFLOW DIRECTION (RH-D UNITS ONLY) 13

5.8 CONNECT ELECTRIC SERVICE 13

5.8.1 Line Voltage Wiring Entry Point 13

5.9 CONNECT THERMOSTAT (RH-W ONLY) 13

5.9.1 Low Voltage Wiring Entry Point (RH-W Only) 17

5.10 SET CONTROLLER POTENTIOMETER (RH-D ONLY) 17

6.0 WIRING SCHEMATICS 18

6.1 RH-D 120 VAC 18

6.2 RH-D 208/240 VAC (1,2,3,4,5 AND 6 KW) 18

6.3 RH-D 208/240 VAC (8,10 AND 11.5 KW) 19

6.4 RH-W 120 VAC 19

6.5 RH-W 208/240 VAC (3,4,5,6 KW) 20

6.6 RH-W 208/240 VAC (8,10,11.5 KW) 20

7.0 MAINTENANCE 21

7.1 RH-D ANNUAL MAINTENANCE 21

7.2 RH-W ANNUAL MAINTENANCE 21

7.3 RH-D TROUBLE SHOOTING 21

7.3.1 Testing AFS and S1 Sensors 21

7.3.2 Testing Control Modules D21-T and D22-T 21

7.3.3 Testing Heating Elements 22

7.3.4 Testing the Transformer 22

7.4 RH-W TROUBLE SHOOTING 22

7.4.1 Testing the CTH291 Thermostat 22

7.4.2 Testing the S2 Airflow Sensor 22

7.4.3 Testing the PSSR Control Module 22

7.4.4 Testing the SSR 23

7.4.5 Testing the Heating Elements 23

7.4.6 Testing the Transformer 23

7.5 SEQUENCE OF OPERATION 23

7.5.1 RH-D Heaters 23

7.5.2 RH-W Heaters 24

8.0 FACTORY ASSISTANCE 24

9.0 WARRANTY 24

10.0 REPAIR PARTS 25

10.1 RH-D 1,2,3,4,5,6 KW REPAIR PARTS 25

10.2 RH-D 8,10,11.5 KW REPAIR PARTS 25

10.4 RH-W 8,10,11.5 KW REPAIR PARTS 26

10.3 RH-W 1,2,3,4,5,6 KW REPAIR PARTS 26

11.0 ENGINEERING AND PERFORMANCE DATA 27

RH-D Heater (typ) 7

RH-D Controls (typ) 7

RH-W Heater (typ) 8

RH-W Controls (typ) 8

Wall Thermostat (typ) 8

MC-C Occupancy Sensor, Ceiling Mount 9

TC7D-W Wall Mount Time Clock 9

MC-W Occupancy Sensor, Wall Mount 9

TC7D-E Time Clock 9

RH-D and RH-W 6” Duct Collar Dimensioned Dwg 10

RH-D and RH-W 8” Duct Collar Dimensioned Dwg 10

RH-D and RH-W 10” Duct Collar Dimensioned Dwg 11

RH-D 12” Duct Collar Dimensioned Dwg 11

Ventilation Clearance 12

Thermostat Wiring Illustration 15

DIP Switch Positions 15

Comfort Mode Screen Shot 16

Economy Mode Screen Shot 16

Wiring Termination Illustration 17

RH-D 1,2,3,4,5,6 KW Repair Parts 25

RH-D 8,10,11,5 KW Repair Parts 25

RH-W 1,2,3,4,5,6 KW Repair Parts 26

RH-W 8,10,11.5 KW Repair Parts 26