1.800.627.44998

EV-Series Premium

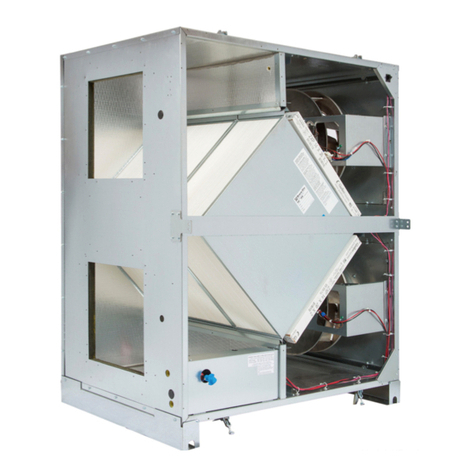

ERV

1.0 OVERVIEW 10

1.1 DESCRIPTION .......................................................10

1.2 OPERATING MODES ..............................................10

1.3 UNIT WEIGHTS......................................................11

2.0 COMPONENT DESCRIPTION 11

2.1 CABINET ..............................................................11

2.1.1 Removable Door with Interlock Switch ............................... 11

2.2 FANS....................................................................11

2.3 CONTROLLER .......................................................11

2.3.1 Controller Power Supply.................................................... 11

2.4 DUCTS .................................................................12

2.5 ENTHALPIC CORE .................................................13

2.6 FILTERS ...............................................................14

2.7 CONTROLS TERMINAL STRIP ................................14

3.0 UNIT PLACEMENT 14

3.1 MOUNTING THE UNIT ............................................15

3.2 SERVICE CLEARANCES .........................................15

3.3 AC POWER SOURCE ..............................................15

3.4 LOAD BEARING CAPACITY OF SUPPORTS ..............15

4.0 INSTALLATION 16

4.1 USER-SUPPLIED INSTALLATION MATERIALS..........16

4.2 FACTORY-RECOMMENDED ELECTRIC SERVICE

ENTRY .......................................................................16

4.3 FACTORY-RECOMMENDED LOW VOLTAGE SERVICE

ENTRY .......................................................................16

4.4 ATTACHING DUCTS ...............................................16

4.5 SELECTING AIRFLOW SETTINGS............................16

4.6 BALANCING AIRFLOWS .........................................16

4.7 WIRING SCHEMATICS............................................18

4.8 LOW VOLTAGE WIRING DIAGRAMS.........................19

4.8.1 Low Speed/High Speed Modes Continuous ........................ 19

4.8.2 Low Speed Continuous/High Speed SWITCHED............................... 19

5.0 OPERATION 19

5.1 MANOMETER READINGS AT COMMISSIONING .......19

5.2 AIRFLOW READINGS AT COMMISSIONING..............20

5.2.1 Conversion of Pressure Drop to Airflow .............................20

5.2.2 Continuous Mode (low speed) ...........................................20

5.2.3 Boost Mode (high speed) ..................................................20

6.0 MAINTENANCE 20

6.1 MAINTENANCE AFTER 30 DAYS OPERATION ..........21

6.2 RECALIBRATION OF AIRFLOWS .............................21

6.3 DOOR REMOVAL ...................................................21

6.4 SERVICE PARTS....................................................21

7.0 TROUBLESHOOTING 22

7.1 INDICATION OF PROBLEM .....................................22

7.2 EV PREMIUM HAS AIRFLOW BUT IS MAKING

NOISE ........................................................................22

7.3 NO APPARENT AIRFLOW FROM THE EV

PREMIUM...................................................................22

7.4 INADEQUATE OR REDUCED AIRFLOW FROM THE

EV PREMIUM..............................................................23

7.5 EV PREMIUM FAILS TO RUN IN EITHER LOW

SPEED OR HIGH SPEED ..............................................23

7.6 NO APPARENT REASON FOR LOW AIRFLOW ..........23

8.0 FACTORY ASSISTANCE 23

TABLE OF CONTENTS