1.800.627.44992

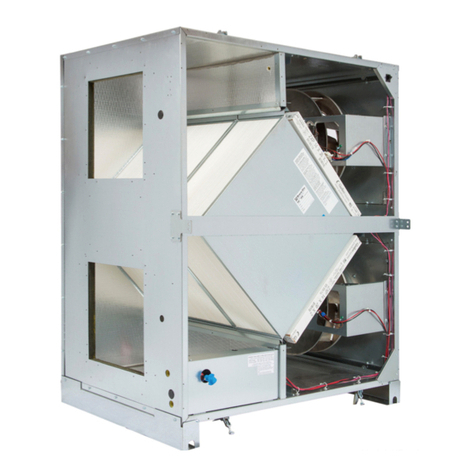

Integral Indirect Gas-Fired Heat Module

OPTION

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in seri-

ous injury, death or property damage.

Be sure to read and understand the installation, operation

and service instructions in this manual.

Improper installation, adjustment, alteration, service or

maintenance can cause serious injury, death or property

damage.

AVERTISSEMENT

RISQUE D’INCENDIE OU D’EXPLOSION

Le non repsect des mises en garde pourrait entraîner des

blessures graves, la mort ou des pertes matérielles.

Prendre soin de lire et de comprendre les instructions

d’installation, de fonctionnement at d’entrention contenues

dans ce guide.

Une installation, un réglage, une modification, une répara-

tion ou un entretien inapproprié peut entraîner des bless-

ures graves, la mort ou des pertes matérielles.

WARNING

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

uDo not try to light any appliance.

uDo not touch any electrical switch; do not use any phone

in your building.

uLeave the building immediately.

uImmediately call your gas supplier from a phone remote

from the building. Follow the gas supplier’s instructions.

uIf you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

AVERTISSEMENT

Ne pas entreposer ni utiliser d’essence ou autre vapeurs ou

liquides inflammable à proximité de cet appareil ou de tout

autre appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

uNe tentez pas d’allumer un appareil.

uNe touchez pas à un interrupteur; n’utilisez pas de télé-

phone dans l’édifice où vous vous trouvez.

uSortez de l’édifice immédiatement.

uAppelez immédiatement le fournisseur de gaz à par-

tir d’un téléphone à l’exterieur de l’édifice. Suivez les

instructions du fournisseur de gaz.

uSi vous ne pouvez joindre le fournisseur de gaz, appelez

les pompiers.

L’installation at les réparations doivent être confiées à un

installateur qualifié ou au fournisseur de gaz.

WARNING

ARC FLASH AND ELECTRIC SHOCK HAZARD

Arc flash and electric shock hazard. Disconnect all electric

power supplies, verify with a voltmeter that electric power

is off and wear protective equipment per NFPA 70E before

working within electric control enclosure. Failure to comply

can cause serious injury or death.

Customer must provide earth ground to unit, per NEC, CEC

and local codes, as applicable.

Before proceeding with installation, read all instructions,

verifying that all the parts are included and check the

nameplate to be sure the voltage matches available utility

power.

The line side of the disconnect switch contains live

high-voltage.

The only way to ensure that there is NO voltage inside the

unit is to install and open a remote disconnect switch and

verify that power is off with a volt

meter. Refer to unit electrical schematic.Follow all local

codes.

AVERTISSEMENT

RISQUE FLASH D’ARC ET DE CHOC ÉLECTRIQUE

Risque d’arc êlectrique et de choc électrique. Débrancher

toutes les alimentation électrique, vérifier avec un voltmètre

que l’alimentation électrique est coupée et portez des vête-

ments de protection conformément à la norme NFPA 70E

avant de travailler dans la console de commande électrique.

Le non-respect peut entraîner des blessures graves ou la

mort.

Le client doit fournir la terre à l’unité, selon les codes NEC,

CEC et locaux, selon le cas.

Avant de procéder à l’installation, lisez toutes les instruc-

tions, vérifiez que toutes les pièces sont incluses at vérifier

la plaque signalétique pour vous assurer que la tension

correspond à la puissance disponible du réseau.

Le côté entrée du sectionneur contient une haute tension

active.

La seule façon de s’assurer qu’il n’y a pas de tension à

l’intérieur de l’unité est d’installer et d’ouvrir un interrupteur

de déconnexion à distance et de vérifier que l’alimentation

est coupée à l’aide d’un voltmètre. Référe-vous au schéma

électrique de l’appareil.

Suivez tous les codes locaux.