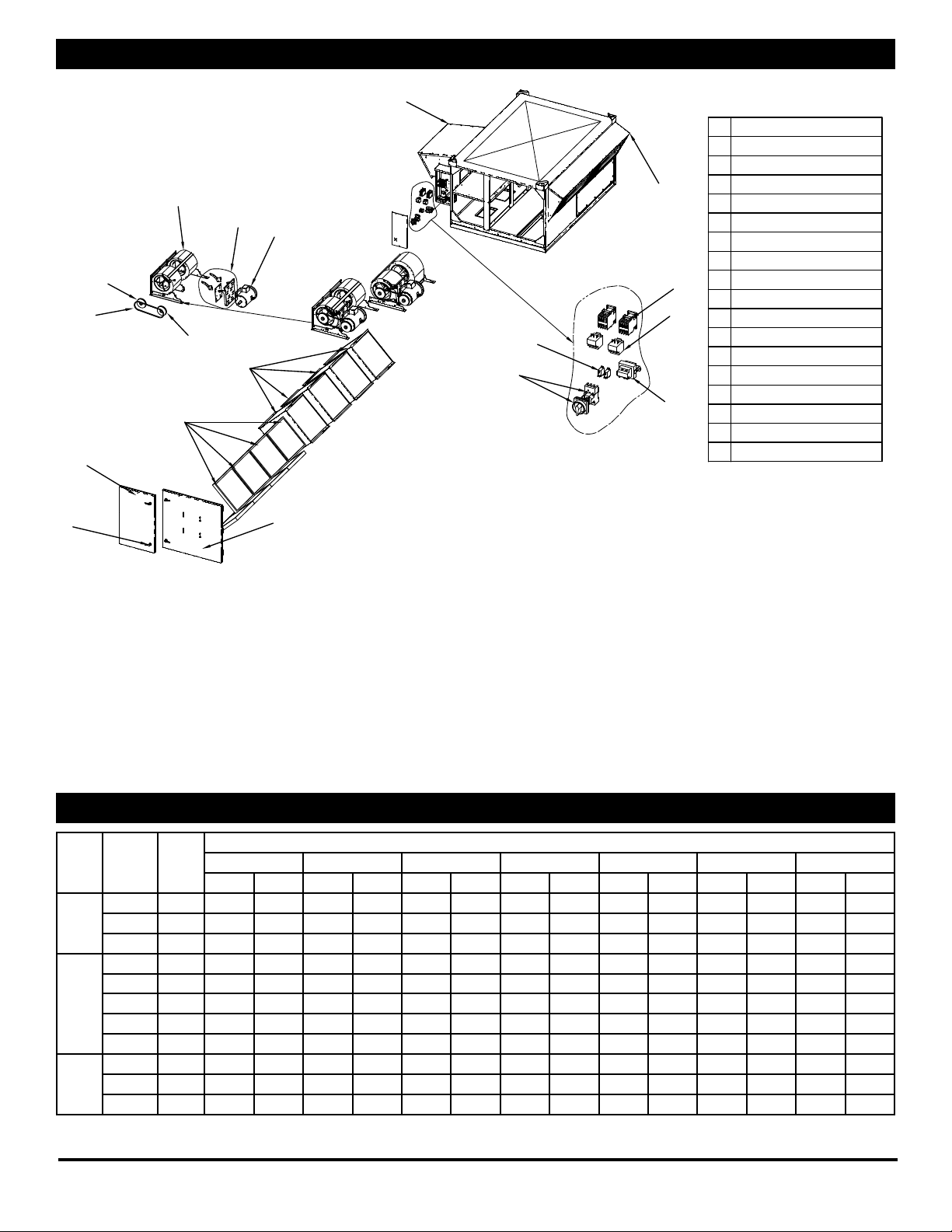

HE4XRT Due to continuing product development, specications are subject to change without notice. © 2012 RenewAire LLC

134775_005 HE4XRTMan_Jan12.indd Revised 01/2012 www.renewaire.com Page 9

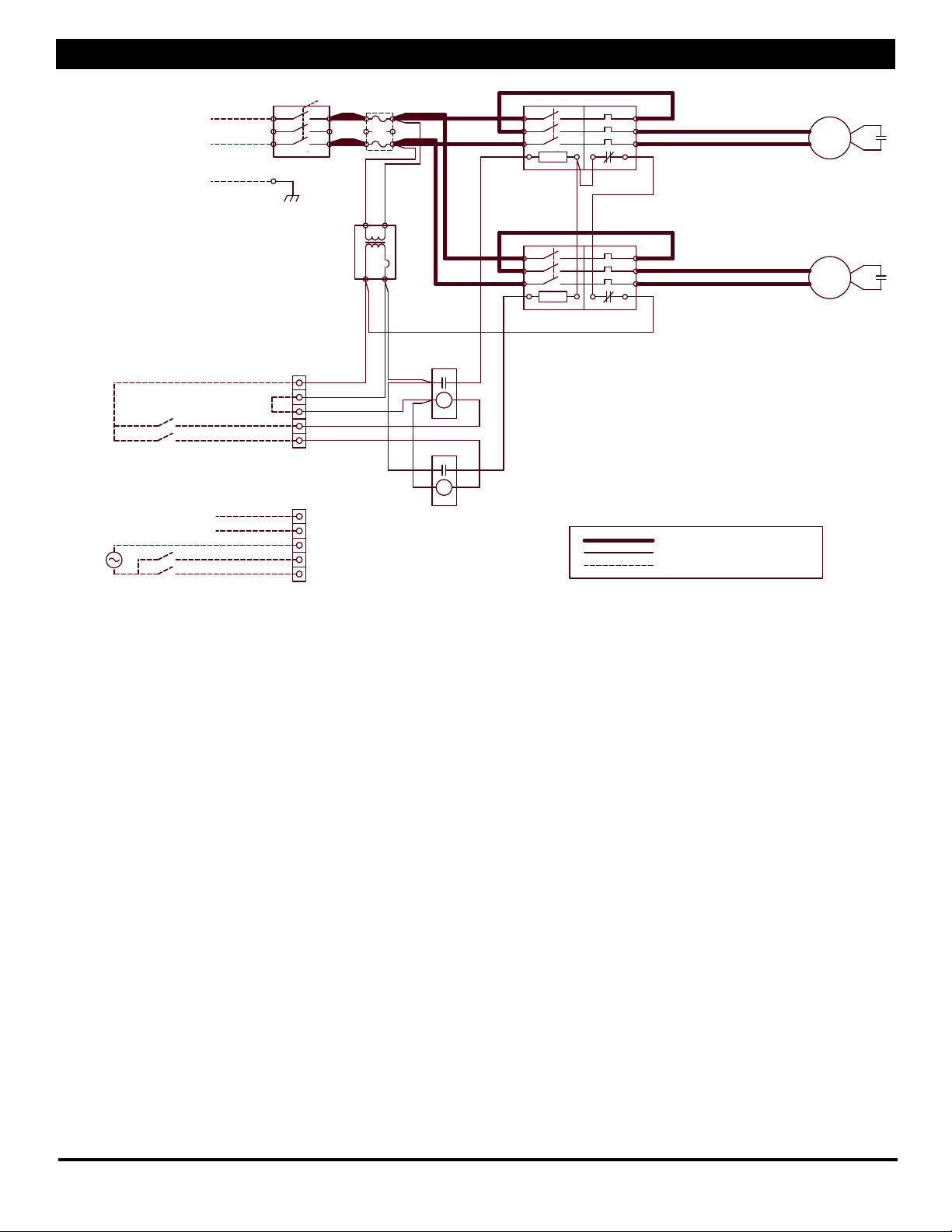

E. Control System with 2 Non-powered Relay Contacts: Use

this schematic if the external control system provides no

voltage or current at its output contacts. Install jumper

(provided) between terminals 2 & 3. Connect one side of

each of the output contacts to Terminal 1. Connect the

other side of the output contact to control the FA Blower

to Terminal 4, and the output contacts to control the EA

Blower to Terminal 5.

Control Wiring Schematics

NOTE: The simplied schematics below show only the relevant

portions of the low-voltage control circuit in the ERV unit and

representational external control approaches. See the

complete unit schematics elsewhere in this manual.

C. Control Sending 24VAC “On” Signal (from an external

power source) to ERV: Make sure jumper is NOT installed

between Terminals 2 & 3. Now you safely can apply 24VAC

to the Terminals 3 & 4 to operate the ERV’s Isolation Relay

for OA/FA Blower. Install jumper (provided) between

terminals 4 & 5 to operate the ERV’s Isolation Relay for

the RA/EA Blower.

D. Control operating on Unit’s 24VAC Power Supply: 24VAC

power is available at the Terminals 1 & 2. CAUTION:

external control system should not draw more than 8VA.

Install jumper (provided) between terminals 2 & 3.

Connect the switched output of the Control to Terminal

4 to operate the ERV’s Isolation Relay for OA/FA Blower.

Install jumper (provided) between terminals 4 & 5 to

operate the ERV’s Isolation Relay for the RA/EA Blower.

F. Control System Sending two 24VAC “On” Signals from

an external power source: Make sure the jumper is NOT

installed between Terminals 2 & 3. Now you safely can

apply one of the 24VAC signals to Terminals 3 & 4 to operate

the ERV’s isolation relay for the Fresh Air Blower. Apply

the second 24VAC signal to Terminals 3 & 5 to operate the

ERV’s isolation relay for the Exhaust Blower (make sure the

polarity of each wire connected to Terminal 3 is the same).

Make sure the control provides no voltage or current at its

output terminals.

Supply only 24VAC (not VDC) from a Class II Power Source.

A. Single 2-wire Control, unpowered: Use schematic below

if the control requires no power from the unit to operate

and acts like a simple on/off switch. The control must not

supply any power to the ERV unit. Install jumper (provided)

between terminals 2 & 3. Connect the control’s contacts to

terminals 1 & 4 to operate the ERV’s Isolation Relay for OA/

FA Blower. Install jumper (provided) between terminals 4 &

5 to operate the ERV’s Isolation Relay for the RA/EA Blower.

Supply only 24VAC (not VDC) from a Class II Power Source.

G. Control System Operating Isolation Dampers with End

Switches: Use Isolation Dampers with electrically separate

end switches. The end switches are used to separately

control the ERV unit’s Isolation Relays. This ensures that

each damper is open before the respective blower starts up.

NOTE: Because the ERV’s Motor Starters will only be

operating once the Dampers are open, the power draw

of the Damper Actuators is allowed to be as much as 35VA

while opening (including power draw of the external

control system, if any). However, the power draw of the

fully-opened (stalled) Actuators (and external control

system if any) must be less than 8VA. (Most damper

actuators have much lower power draws.)

B. Single 2-wire Control on separate Power Supply, no power

present at Control Output: Wire as shown for the Single

2-wire control (A. above).

Connect Terminals 2 & 3

Connect Switch between Terminals 1 & 4

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

24VAC FROM AN EXTERNAL SOURCE

Unit's 24VAC

Power Supply

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

AN EXTERNAL CONTROL USING UNIT'S

24VAC POWER SUPPLY

24VAC Available at Terminals 1 & 2

Unit's 24VAC

Power Supply

Unit's 24VAC

Power Supply

Connect Terminals 2 & 3

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

TWO EXTERNAL RELAY CONTACTS

SUPPLYING 24VAC FROM AN

EXTERNAL SOURCE Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

Connect Terminals 4 & 5

Connect Switch between Terminals 1 & 4

Connect Terminals 4 & 5

Connect Terminals 4 & 5

Connect Terminals 2 & 3

1

2

3

4

5

MPU

Connect Terminals 2 & 3

Connect Switch between Terminals 1 & 4

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

24VAC FROM AN EXTERNAL SOURCE

Unit's 24VAC

Power Supply

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

AN EXTERNAL CONTROL USING UNIT'S

24VAC POWER SUPPLY

24VAC Available at Terminals 1 & 2

Unit's 24VAC

Power Supply

Unit's 24VAC

Power Supply

Connect Terminals 2 & 3

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

TWO EXTERNAL RELAY CONTACTS

SUPPLYING 24VAC FROM AN

EXTERNAL SOURCE Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

Connect Terminals 4 & 5

Connect Switch between Terminals 1 & 4

Connect Terminals 4 & 5

Connect Terminals 4 & 5

Connect Terminals 2 & 3

1

2

3

4

5

1

2

3

4

5

MPU

Connect Terminals 2 & 3

Connect Switch between Terminals 1 & 4

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

24VAC FROM AN EXTERNAL SOURCE

Unit's 24VAC

Power Supply

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

AN EXTERNAL CONTROL USING UNIT'S

24VAC POWER SUPPLY

24VAC Available at Terminals 1 & 2

Unit's 24VAC

Power Supply

Unit's 24VAC

Power Supply

Connect Terminals 2 & 3

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

TWO EXTERNAL RELAY CONTACTS

SUPPLYING 24VAC FROM AN

EXTERNAL SOURCE Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

Connect Terminals 4 & 5

Connect Switch between Terminals 1 & 4

Connect Terminals 4 & 5

Connect Terminals 4 & 5

Connect Terminals 2 & 3

1

2

3

4

5

MPU

Connect Terminals 2 & 3

Connect Switch between Terminals 1 & 4

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

24VAC FROM AN EXTERNAL SOURCE

Unit's 24VAC

Power Supply

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

AN EXTERNAL CONTROL USING UNIT'S

24VAC POWER SUPPLY

24VAC Available at Terminals 1 & 2

Unit's 24VAC

Power Supply

Unit's 24VAC

Power Supply

Connect Terminals 2 & 3

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

TWO EXTERNAL RELAY CONTACTS

SUPPLYING 24VAC FROM AN

EXTERNAL SOURCE Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

Connect Terminals 4 & 5

Connect Switch between Terminals 1 & 4

Connect Terminals 4 & 5

Connect Terminals 4 & 5

Connect Terminals 2 & 3

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

MPU

Connect Terminals 2 & 3

Connect Switch between Terminals 1 & 4

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

24VAC FROM AN EXTERNAL SOURCE

Unit's 24VAC

Power Supply

UNIT INTERNAL CONTROL WIRING

(SIMPLIFIED)

AN EXTERNAL CONTROL USING UNIT'S

24VAC POWER SUPPLY

24VAC Available at Terminals 1 & 2

Unit's 24VAC

Power Supply

Unit's 24VAC

Power Supply

Connect Terminals 2 & 3

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

A SWITCH OR NON-POWERED

CONTROL USING UNIT'S 24VAC POWER

SUPPLY Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

UNIT INTERNAL CONTROL WIRING

CIsolation Relay Coil (Fresh Air)

(SIMPLIFIED)

TWO EXTERNAL RELAY CONTACTS

SUPPLYING 24VAC FROM AN

EXTERNAL SOURCE Unit's 24VAC

Power Supply

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

CIsolation Relay Coil (Fresh Air)

CIsolation Relay Coil (Exhaust Air)

Connect Terminals 4 & 5

Connect Switch between Terminals 1 & 4

Connect Terminals 4 & 5

Connect Terminals 4 & 5

Connect Terminals 2 & 3

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5