5www.renishaw.com/tb20TB20 quadrature trigger box

Safety information

ENSURE THAT YOU READ AND UNDERSTAND THE TB20 USER GUIDE

BEFORE USING ANY TB20.

The TB20 can be used in a variety of environments and applications.

To ensure the safety of the user and other personnel in the vicinity it is

therefore paramount that a comprehensive risk assessment is carried out

for the machine under test before using the TB20. This should be carried

out by qualied users (requiring machine competency, applicable technical

knowledge and a trained risk assessor) with consideration for the safety of all

personnel. The risks identied must be mitigated prior to using the product.

The risk assessment should pay particular attention to machine, manual

handling, mechanical, laser, electrical and power.

General safety information

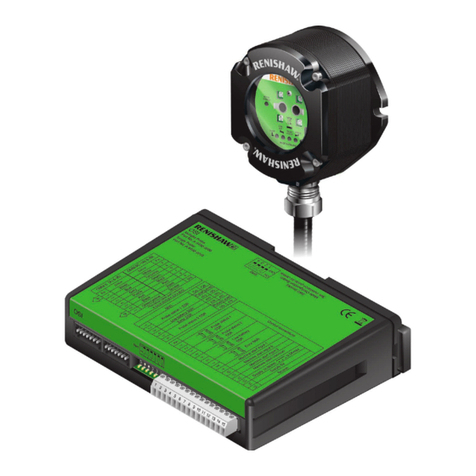

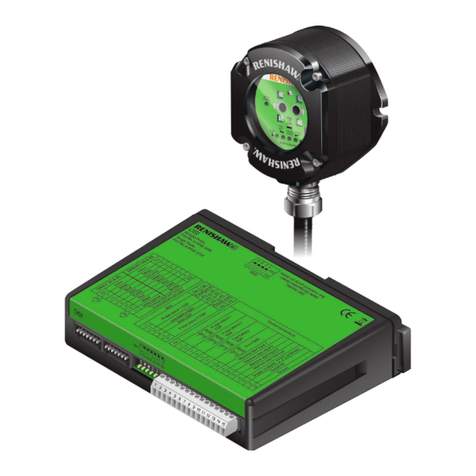

The TB20 quadrature trigger box is designed for integration into the primary

position feedback loop of a motion system. It is essential that the system is

installed in accordance with the instructions in the installation manuals and it

is the responsibility of the system integrator to ensure that, in the event of a

failure of any part of the TB20, the motion system remains safe.

In motion systems with powers or speeds capable of causing injury, safety

protection measures must be included in the design. It is recommended that

satisfactory operation of these protection measures is veried before the

feedback loop is closed. The following safety protection measures should

be used. For closed loop operation it is the sole responsibility of the system

integrator to select appropriate measures for their application.

1� The axis must include physical limit switches which, when tripped,

will stop axis motion before damage occurs (soft limits alone are

insufcient). Note that in the case of thermally compensated systems,

positional corrections of several hundred ppm are possible. This should

be taken into account when dening the relative positions of soft and

hard axis limits.

2� Cable breakage detection (encoder disconnect). The position feedback is

provided as differential line driven pairs. Failure in the cable or of the line

drivers can be detected by checking these differential pairs are always

being driven in opposing states. If the lines are not in opposing states,

the motion must be stopped.

3� Motor torque monitoring. If the motor torque exceeds an expected limit,

the axis of motion must be stopped.

4� The machine must include an emergency stop button.

5� Following error detection. If the difference between the controller demand

position and the axis feedback position exceeds an expected limit, the

axis motion must be stopped.

6� Guards, viewing windows, covers and interlocks may be used to prevent

user access to hazardous areas, and to contain ejected parts or materials.

7� If the machine includes an independent tacho (velocity) feedback system,

this should be cross-checked with the position feedback. For example, if

the tacho indicates the axis is moving, but the position feedback doesn’t,

the axis motion must be stopped.

NOTE: In the case of measures 5 to 7, the limits need to be selected carefully

depending on the application and the type of position compensation selected

to avoid false alarms.