2

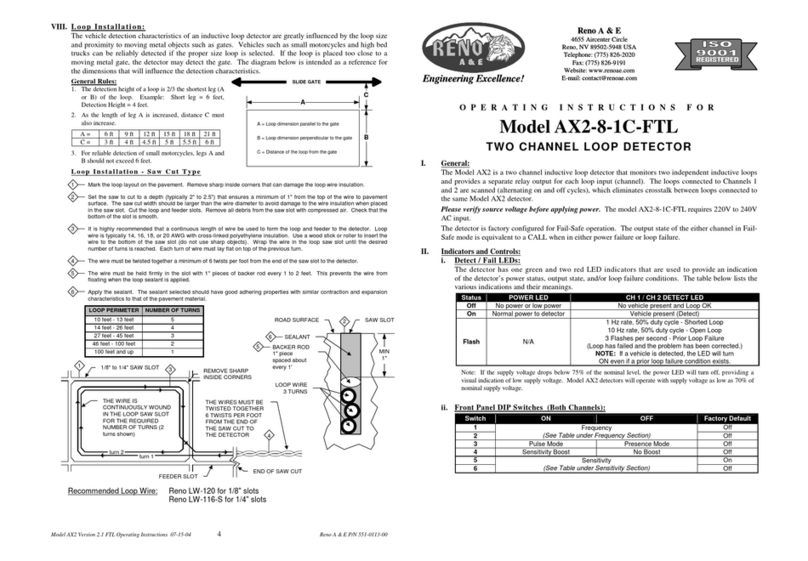

ii Front Panel DIP Switches (Both Channels)

Frequency

(See Table under Frequency Section)

Sensitivity

(See Table under Sensitivity Section)

Frequency (DIP Switches 1 and 2)

Loops connected to channels 1 and 2 of a Model AX2DL-XP detector cannot crosstalk (i.e. interfere with each

other). In situations where loop geometry forces loops to be located in close proximity to one another and the

loops are connected to different detectors, it may be necessary to select different frequencies for each loop to avoid

loop interference. DIP switches 1 and 2 can be used to configure the detector to operate at one of four frequencies

corresponding to Low, Medium / Low, Medium / High, and High as shown in the table below.

NOTE: After changing any frequency switch setting(s), the detector must be reset by momentarily changing

one of the other switch positions or pressing the front panel RESET pushbutton.

* Factory default setting.

Presence / Pulse Mode (DIP Switch 3):

Each channel has two modes of operation, Presence or Pulse. When in Pulse mode (DIP switch 3 set to ON), a 250

millisecond pulse is output each time a vehicle enters the loop detection area. When in Presence mode (DIP switch

3 set to OFF), the channel’s output operates in True PresenceTM Mode and the detector channel will hold a Call

output as long as a vehicle is present and power is not removed or reset applied. True PresenceTM hold time applies

only for normal size automobiles and trucks and for normal size loops (approximately 12 ft2to 120 ft2). The

factory default setting is OFF (Presence Mode).

Sensitivity Boost (DIP Switch 4)

DIP switch 4 can be turned ON to increase sensitivity during the detect period without changing the sensitivity

during the no detect period. The boost feature has the effect of temporarily increasing the sensitivity setting by up

to two levels. When a vehicle enters the loop, the detector automatically boosts the sensitivity level. As soon as no

vehicle is detected, the detector immediately returns to the original sensitivity level. This feature is particularly

useful in preventing dropouts during the passage of high bed vehicles. The factory default setting is OFF (no

Sensitivity Boost).

Sensitivity (DIP Switches 5 and 6)

Each channel has four (4) sensitivity levels. DIP switches 5 and 6 select one of the four sensitivity levels available

as shown in the table below. Use the lowest sensitivity setting that will consistently detect the desired type(s) of

vehicle(s) that must be detected. Do not use a sensitivity level higher than necessary.

Sensitivity Level (-ΔL/L)

* Factory default setting.

III Reset

Pushing the front panel mounted pushbutton labeled RESET or changing any DIP switch (except 1 or 2) will reset

the detector. After changing the frequency selection DIP switches, the detector must be reset.

IV Power Down Memory

When power is removed, the detector automatically remembers the status of the loop. During the loss of power,

vehicles may enter or leave the loop detection area. When power is restored, the detector will correctly determine

the current loop status and output a Call if a vehicle is in the loop detection area. If the loop detection area is

vacant, a Call will not be output. (A power loss power dip of any duration will not bring a gate arm down onto cars

as they wait at the gate). IMPORTANT: After installing and applying power to the Model AX2 detector,

momentarily push the RESET button to clear the Power Down Memory. This initializes the detector to the loops

that are connected and clears the memory of any previous loop information.

V Failed Loop Diagnostics

Each channel’s DETECT LED indicates whether or not the loop connected to the channel is currently within

tolerance. If the loop is out of tolerance, the LED indicates whether the loop is shorted (one Hz flash rate) or open

(10 Hz flash rate). If and when the loop returns to within tolerance, the DETECT LED will flash at a three flashes

per second rate to indicate that an intermittent loop fault has occurred and has been corrected. This flash rate will

continue until another loop fault occurs, the detector is reset, or power to the detector is interrupted. If a vehicle

enters the loop detection area while the DETECT LED is indicating an intermittent loop failure, the DETECT

LED will turn on to indicate the presence of the vehicle.