3. GENERAL INSTALLATION STEPS AND

MAINTAINANCE

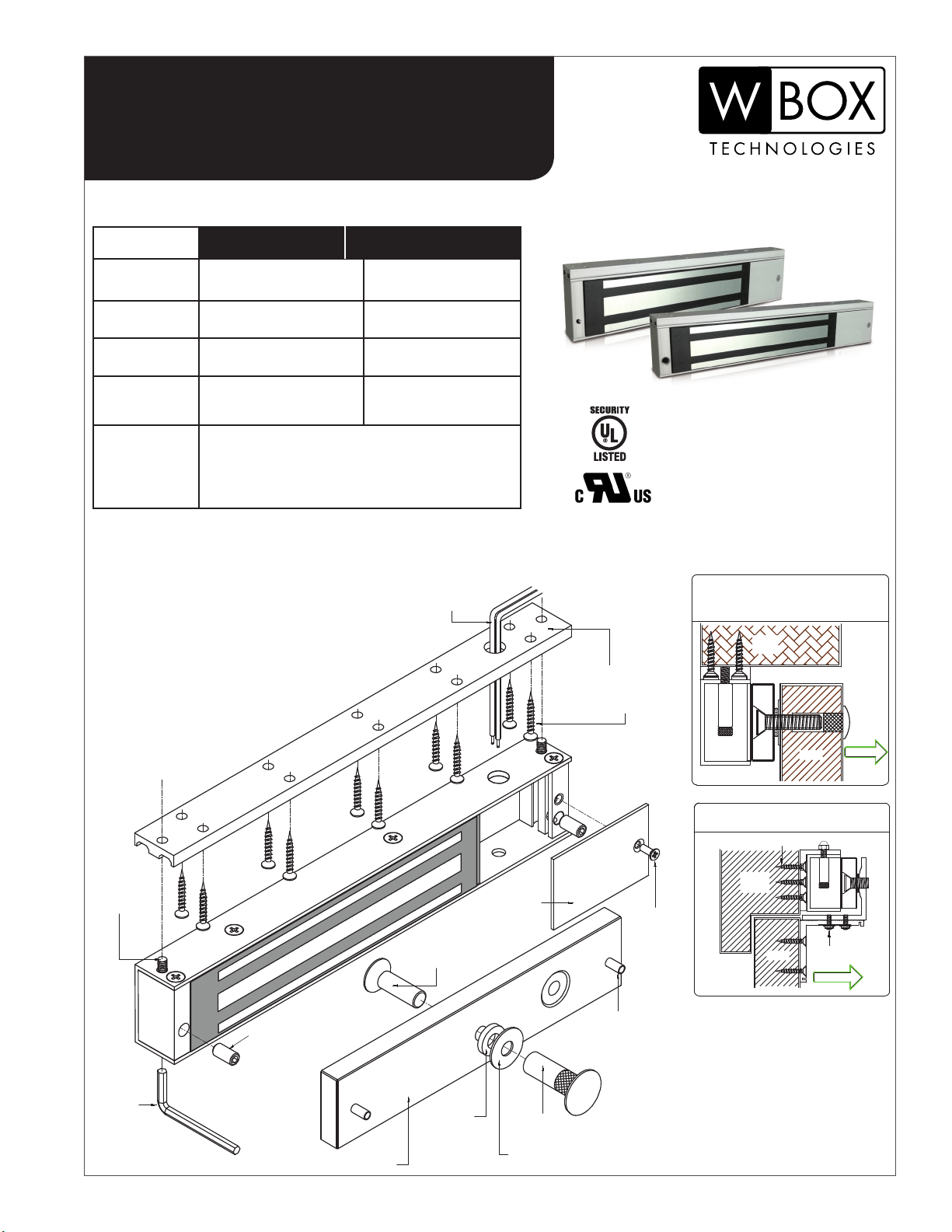

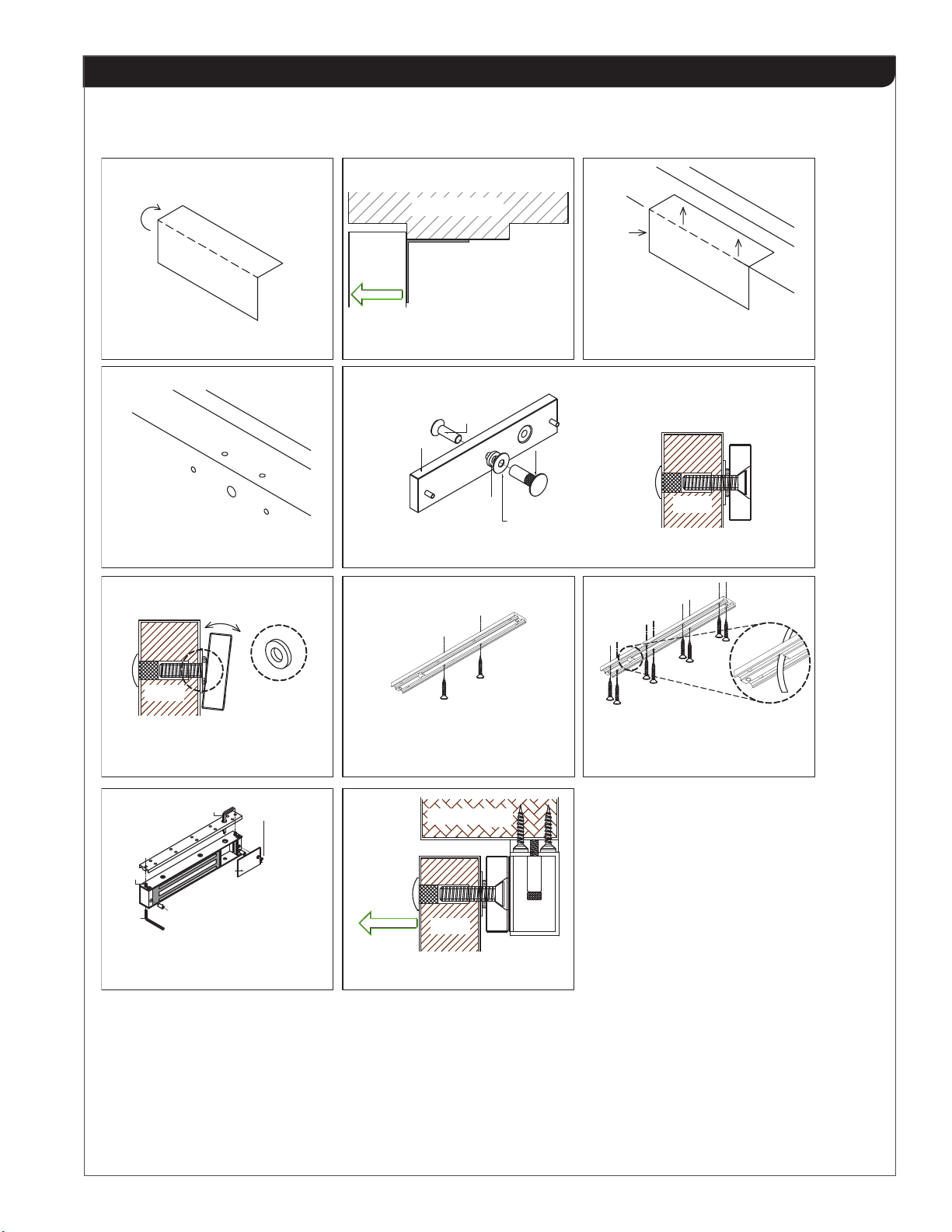

1. Drill the armature plate holes in the door using the sticker

template provided.

2. Attach the armature plate to the door with the hardware

provided as per Figure 5 on page 3.

3. With the door closed, mark the door frame at the edge of

the armature, in order to properly align the electromagnet

to the armature.

4. Attach the mounting plate to the door frame using the

self-tapping screws provided.

Align the mounting plate with the mark from Step 3.

5. Insert the wires through the hole in the mounting plate

and into the electromagnet. Attach the electromagnet

to the mounting plate with the Allen head xing screw.

6. Screw in the anti-tamper nuts to prevent unauthorized

access and make sure to fully tighten the xing screw with

an Allen Key.

7. Connect the power wires in accordance with NFPA 101.

8. Typical wiring method shall be in accordance with CSA

C22.1, Canadian Electrical Code, Part I, Safety Standard

for Electrical Installations, Section 32.

9. It is recommended to apply a light coating of silicon

lubricant to the mating surfaces on a monthly basis to

inhibit rust.

Notes:

Install in an Indoor Dry Location.

Use Caution when Changing Factory Default Setting.

4. TROUBLE SHOOTING

1. Door not locked:

- Incorrect wiring or no power from power supply

2. Reduced holding force:

- Poor contact of electromagnet and armature.

- Be sure armature is loose enough so that it can fully

contact electromagnet along it is the entire length

- Mating surfaces are dirty or damaged.

- Improper input voltage or wire size.

IMPORTANT!

12 / 24 VDC

Power Output

12 VDC

Setting

24 VDC

Setting

12 / 24 VDC

Power Input

+

-

Set the jumper position according

to the power input before

switching ON the power.

600Lb. / 1200Lb. Magnetic Locks Installation Instructions

Page 2 of 4