ii

TABLE OF CONTENTS

1.0 Installation Manual Revision Management........................................................................ 1-1

2.0 Safety................................................................................................................................2-1

Warnings and Cautions ................................................................................................. 2-1

Component Replacement..............................................................................................2-2

Technical Support for Mixer Installation......................................................................... 2-2

3.0 System Installation Overview ............................................................................................ 3-1

Specifications ................................................................................................................ 3-4

4.0 Installation.........................................................................................................................4-6

Shipping ........................................................................................................................ 4-6

Moving the Equipment................................................................................................... 4-6

Leveling the OmniRAM.................................................................................................. 4-6

Installing the Hoist (Optional accessory skip Section 4.4 if not purchased.)................. 4-14

Mounting the Auxiliary Communications Enclosure (ACE)........................................... 4-19

Connect Machine Chilling System ............................................................................... 4-21

Connect Process Heater/Chiller and Process Module (Optional Items)........................ 4-24

Connect Vacuum Module (Optional System) ............................................................... 4-26

Vacuum Pump and Starter Box (Optional System) ...................................................... 4-27

Removing the Shipping Bracket................................................................................. 4-29

Connect Facility Air to the OmniRAM......................................................................... 4-30

Connecting Facility Power to the OmniRAM .............................................................. 4-30

5.0 RAM Basics ...................................................................................................................... 5-1

Operating the OmniRAM ...............................................................................................5-1

LIST OF FIGURES

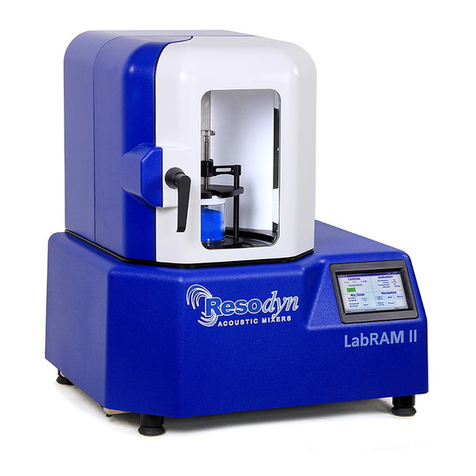

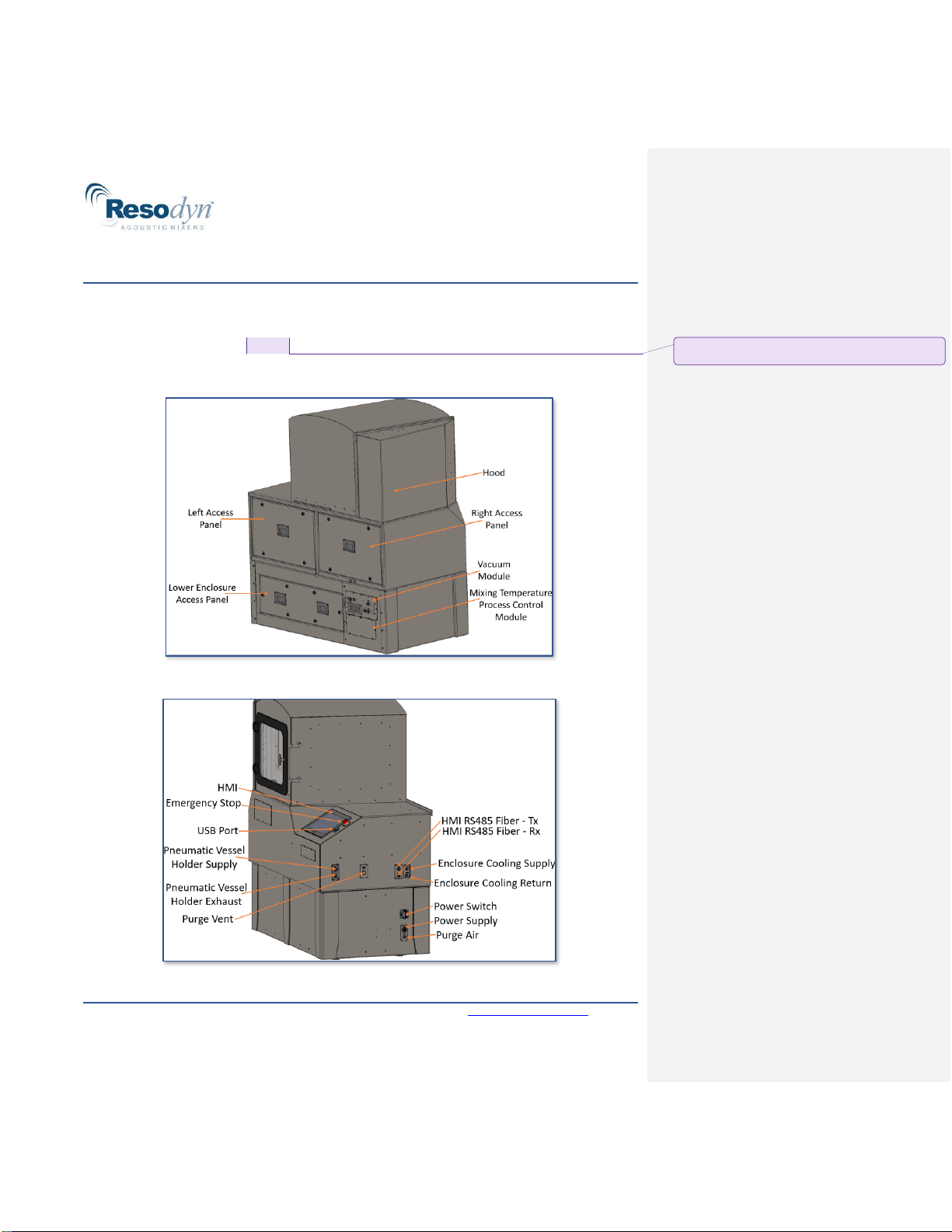

Figure 3-1: OmniRAM Mixer, Rear View, Hood Closed........................................................... 3-1

Figure 3-2: OmniRAM Mixer, Right-Side View......................................................................... 3-1

Figure 3-3: Required Clear Areas Around OmniRAM..............................................................3-2

Figure 4-1: OmniRAM Hoist Attachment ............................................................................... 4-14

Figure 4-2: ACE Bolt Locations............................................................................................. 4-19

Figure 4-3: Vacuum Pump Starter Box Enclosure Bolt Locations.......................................... 4-27

Figure 4-4: Facility Power Connection................................................................................... 4-32

LIST OF TABLES

Table 1-1: Manual Revision History......................................................................................... 1-1

Table 2-1: Warning and Caution Symbols............................................................................... 2-1

Table 2-2: Technical Support for Mixer Installation.................................................................. 2-2

Table 3-1: Figure 3-1 Plumbing and Cable List....................................................................... 3-3

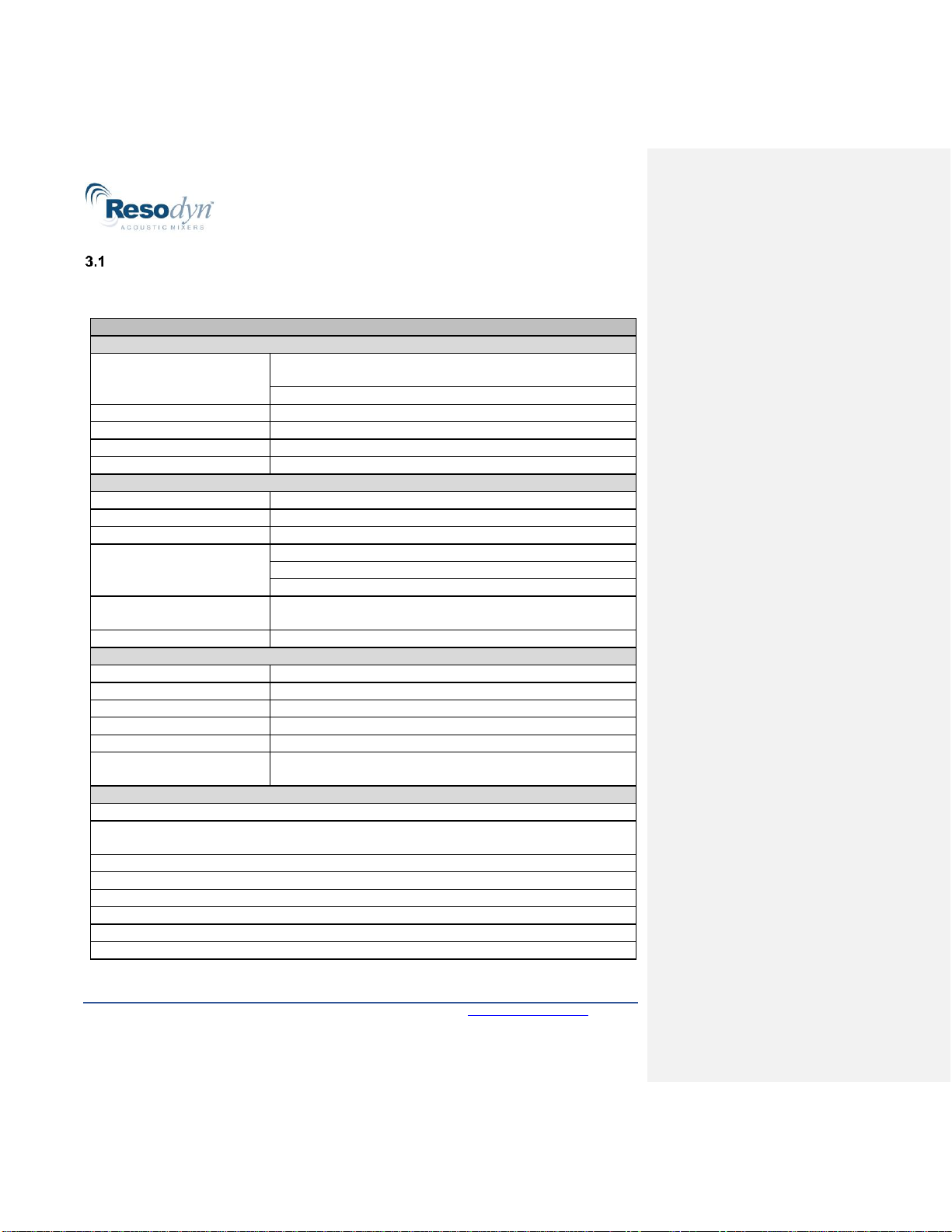

Table 3-3: OmniRAM Mixer Specifications.............................................................................. 3-4

Table 4-1: OmniRAM Pneumatic Hoist Specifications........................................................... 4-17

Table 4-2: OmniRAM Machine Chiller Specifications ............................................................ 4-22

Table 4-3: OmniRAM Process Heater/Chiller Specifications ................................................. 4-24