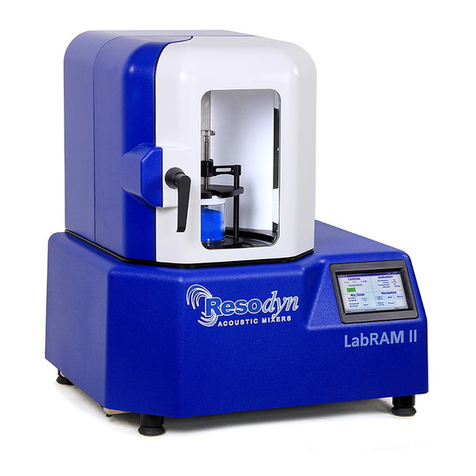

LabRAM II Spray System Instruction Manual

Rev. 042618

Resodyn Acoustic Mixers, Inc. 3 www.resodynmixers.com

Table of Contents

1Introduction .....................................................................................................................................4

2Definitions........................................................................................................................................5

3Safety Information...........................................................................................................................6

3.1 General Safety and Assembly Considerations........................................................6

3.2 Warnings and Cautions...........................................................................................7

3.3 Important Safety Notes...........................................................................................8

4General Notes................................................................................................................................11

4.1 System Description...............................................................................................11

4.2 Voltage Level and Power Consumption ................................................................13

5Installation .....................................................................................................................................14

5.1 Spray System Overall Assembly Pictures.............................................................14

5.2 Spray System Installation......................................................................................16

5.3 Installing the Ultrasonic Atomizer Nozzle Generator .............................................19

5.4 Connect Peristaltic Pump Options to Ultrasonic Nozzle ........................................19

5.5 Connecting Syringe Pump to Ultrasonic Nozzle....................................................20

6Operating Instructions..................................................................................................................21

6.1 Power-up Equipment ............................................................................................21

6.2 LabRAM II Spray System Operation .....................................................................22

6.3 Power-Down.........................................................................................................28

6.4 Maintenance and Cleaning ...................................................................................29

6.5 General Cleaning Instructions...............................................................................32

7Warranty and Service ...................................................................................................................33

7.1 Limited Warranty...................................................................................................33

7.2 Maintenance and Service......................................................................................33

8Supplemental Information............................................................................................................34

8.1 Other Operating Manuals......................................................................................34

8.2 Replacement Parts ...............................................................................................35