LabRAM II Jacketed Vessel Users’ Manual

INTRODUCTION

Resodyn Acoustic Mixers, Inc. 3 010320

1 Introduction

The Resodyn Jacketed Vessel is a processing accessory designed for use with the

Resodyn LabRAM II mixing platform. The Jacketed Vessel allows heating or cooling

before, during, or after the mixing process via heat transfer fluid or “jacket” flowing through

the outer fixture h=enclosing the mixing vessel.

ResonantAcoustic®Mixing (RAM) utilizes acoustic energy to mix liquids, powders,

slurries, and pastes rapidly, efficiently, and thoroughly. Please refer to the Users’ Manual

provided with the LabRAM II mixer for more detailed information about RAM technology

and visit www.resodynmixers.com.

This manual will provide vital LabRAM II Jacketed Vessel information on the following:

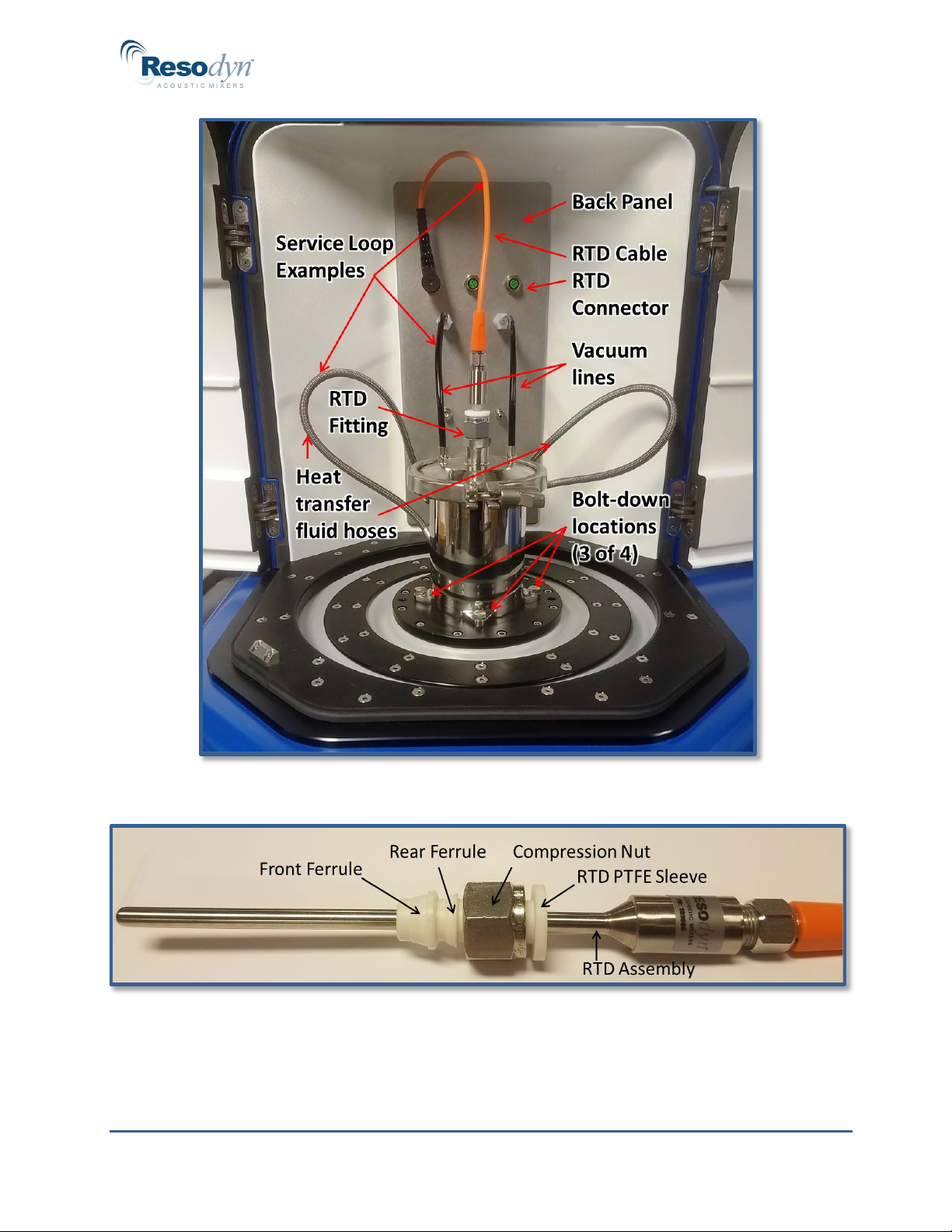

•Understanding the major components

•Setting up the Jacketed Vessel hardware

•Safe operation of the Jacketed Vessel using a LabRAM II

•Cleaning and maintenance of the equipment

•Obtaining additional accessories or replacement parts

Key features of the LabRAM II Jacketed Vessel:

•Control of fluid temperature from 0°F cooling to 302°F heating (-18°C to 150°C)

•Facilitates mix quality when temperature control is required

•Access ports to enable use of the vacuum processing option

•Enables temperature monitoring with access port for RTD hardware

•Removable, replaceable mixing vessel liner in multiple sizes

The Jacketed Vessel system provides the following processing advantages:

•Improved mixing results via constant or ramped temperature operation before,

during, or after mixing

•Control of heating/cooling fluid using LabRAM< II’s integrated Operating System

•Recording of vacuum and temperature measurements

•Durable stainless steel construction is compatible with most mixing materials and

coolants, including steam, water, antifreeze, hot oil, etc.

Not covered in this manual are:

•Details, use, operation, or repair of LabRAM II, Pharma RAM II, or LabRAM II H

mixers. Please refer to those manuals for more information

•Heat transfer fluid heating, cooling, circulation, and control systems.

Call 406 497-5333 for more information about heater chiller cooling options