Resodyn Acoustic Mixers 3 rev 111519

Table of Contents

1Introduction .................................................................................................................... 4

2Definitions ...................................................................................................................... 5

3Safety............................................................................................................................. 6

3.1 General Safety Considerations .................................................................................... 6

3.2 Warnings and Cautions................................................................................................ 6

3.4 Component Replacement ............................................................................................ 7

3.5 Customer Responsibility .............................................................................................. 7

3.6 Handling/Lifting ............................................................................................................ 7

3.7 Mounting...................................................................................................................... 8

3.8 Guards and Safety Devices ......................................................................................... 8

3.9 Technical Support for Mixer Operation:........................................................................ 8

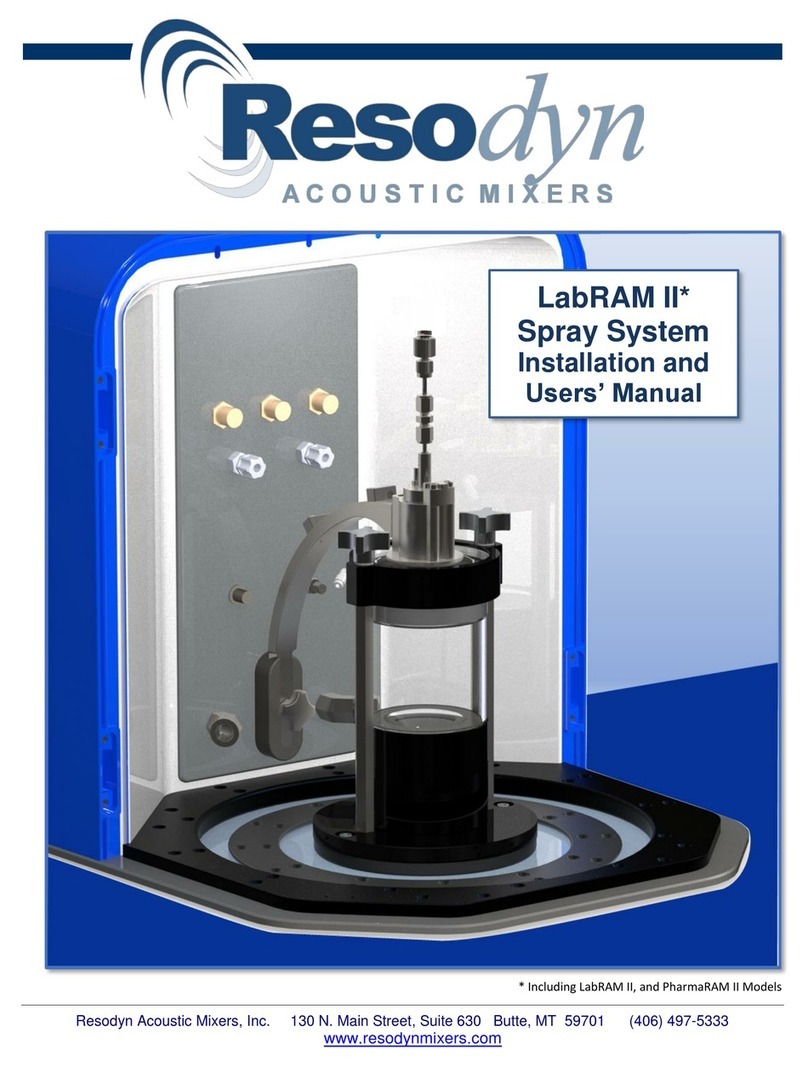

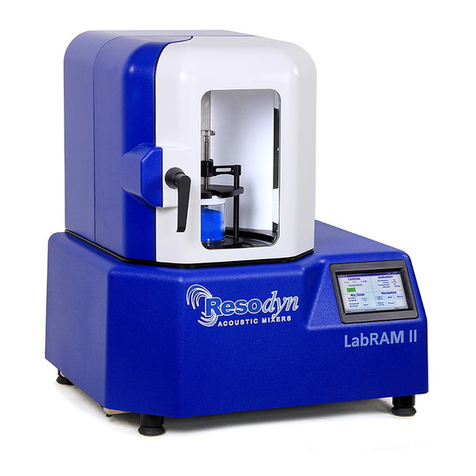

4System Overview ........................................................................................................... 9

4.1 Enclosure..................................................................................................................... 9

4.2 Human Machine Interface (HMI) Control Panel............................................................ 9

4.3 Vacuum Lines and Filters............................................................................................. 9

5System Specifications ...................................................................................................10

5.1 Voltage Requirements ................................................................................................10

5.2 Power Consumption....................................................................................................10

6Installation and Support.................................................................................................11

Unpacking, Lifting, and Placing the Automatic Vacuum System ............................................11

6.1 Connecting Vacuum System to LabRAM I and LabRAM II..........................................11

6.2 Electrical Connections ................................................................................................12

6.3 Filter Cartridge Replacement ......................................................................................13

7Quick Start ....................................................................................................................14

7.1 Setup ..........................................................................................................................14

7.2 Power-Up....................................................................................................................14

8HMI (Human Machine Interface) – Overview .................................................................15

9Care and Maintenance ..................................................................................................16

9.1 Maintenance ...............................................................................................................16

9.2 Cleaning Procedures ..................................................................................................16

9.3 Repairs and Replacement Parts .................................................................................16

9.3.1 Major Repairs...................................................................................................16

9.3.2 Recommended Spare Parts .............................................................................17

9.3.3 Fuse Replacement ...........................................................................................17

9.3.4 Technical Support: ...........................................................................................17

10 Troubleshooting and Service .........................................................................................18