1.0 Genera Information

2.0 Fixing

LST radiators are for use on indirect systems only. The system

should be designed to follow the recommendations of BS5449

or BS6880, as appropriate, with particular care taken to avoid

air entry or water discharge through an open vent. The

installation work must be done in accordance with recognised

good practice and precautions taken to avoid contamination,

which could lead to corrosion. If a corrosion inhibitor or other

water treatment is to be used, the manufacturer’s instructions

must be strictly followed.

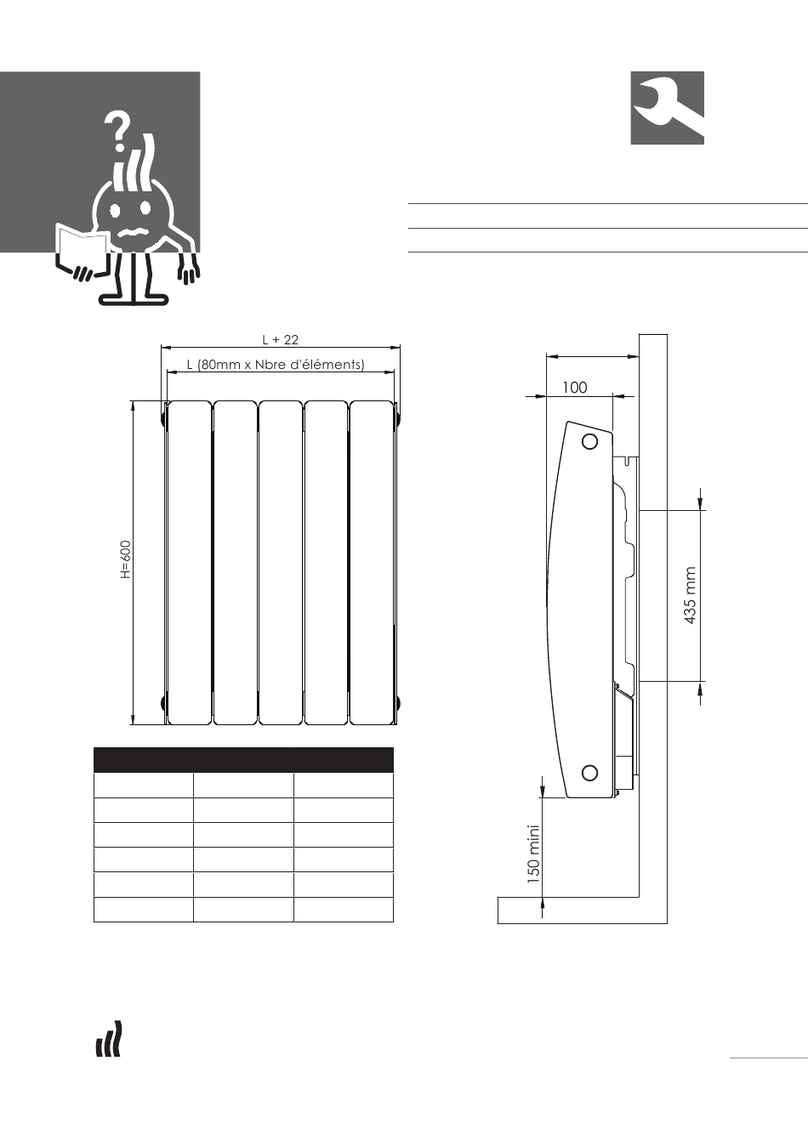

lA pair of templates are supplied with the product to ensure the correct positioning of the wall brackets for the emitter

and the enclosure (see fig. 1).

Emitter Height - B (mm

Enclosure Height - A (mm

LST SUPER

SIDE ELEVATION

LST SUPER EXTRA

SIDE ELEVATION

LOOKING TOWARDS WALL LST SUPER PLUS

SIDE ELEVATION

572 672 872 972

300 400 600 700

Fig. 1 (All measurements are in mm)

IMPORTANT: It is advisable to leave a further 5mm

clearance above any final floor covering to allow for

easy fitting and removal.

3.0 Water Connections

lIf surface mounting pipework is being used, this must be

routed and mounted to run within the rectangular cut-outs

provided at each end of the enclosure. To remove the

cut-out, flex from side to side until the connection is broken.

If pipework enters one side only, the other cut-out should be

left intact.

lCarry out the plumbing connections in the usual way. Fig 1

shows the clearances between the heat emitter and the

enclosure. Ensure that pipework and valves are within these

limits to enable correct fitting of the enclosure.

LST radiators may be fitted with the following types of thermo-

static radiator valves:

4.0 Thermostatic Radiator Va ves

Valve Type Order Code

Connection Options

Close coupled TRV kit CCKTC 333

Remote Adjusting TRV 2TRVADJHEAD2 333

Remote Sensing TRV 2TRVRSHEAD2 3

Direct Fit TRV Kit DIRECTFIT 33

lRemove both security screws.

lLift the LST enclosure out of the wall bracket slots and pull

forward.

lTo reposition the enclosure, lift the enclosure onto the

brackets ensuring correct engagement with the bracket slots.

Replace the security screws.

lIf the unit is fitted with a Close Coupled or Remote TRV kit

then excessive movement of the casing will be restricted by

a safety chain.

5.0 C eaning and Maintenance - LST Enc osure

TBSE TBOE BOE

IMPORTANT: For the correct installation of radiators it is essential that the fixing of the radiator is carried out in such a way

that it is suitable for intended use AND predictable misuse. A number of elements need to be taken into consideration

including the fixing method used to secure the radiator to the wall, the type and condition of the wall itself, and any additional

potential forces or weights that may happen to be applied to the radiator, prior to finalising installation.

LST

*60mm for the 420mm wide version.

Not available for the 420mm wide model.

Order code CCKTC420 = 420 wide model and only available as BOE.