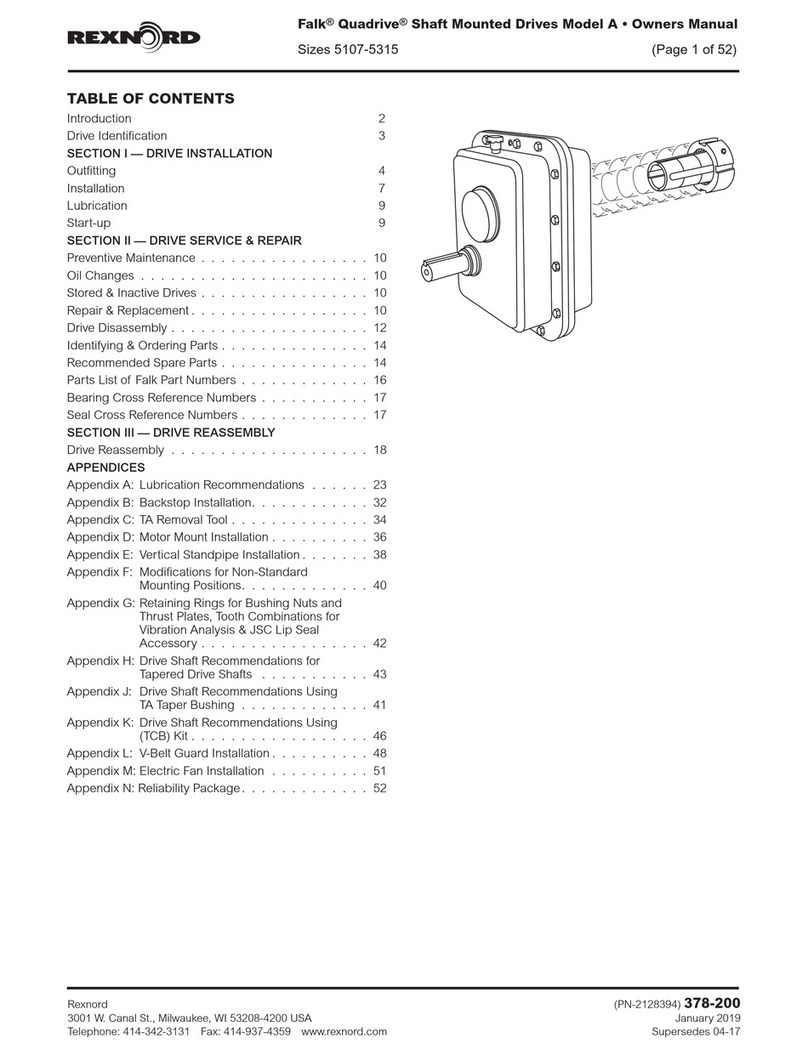

Instructions

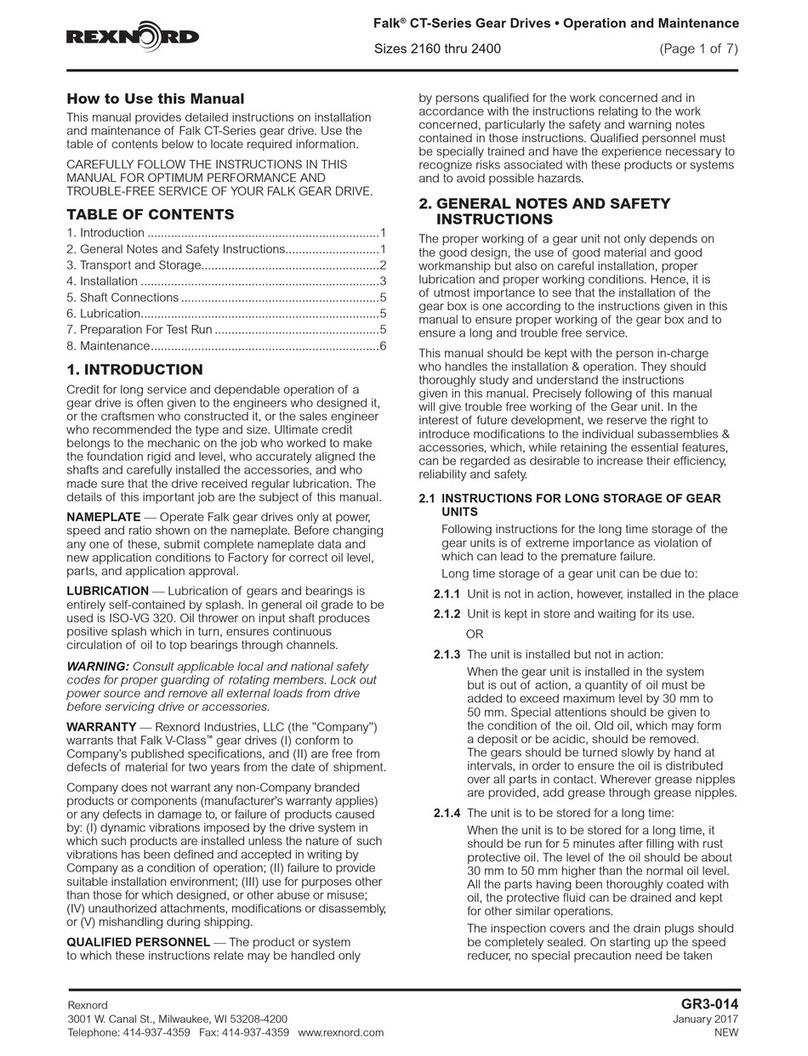

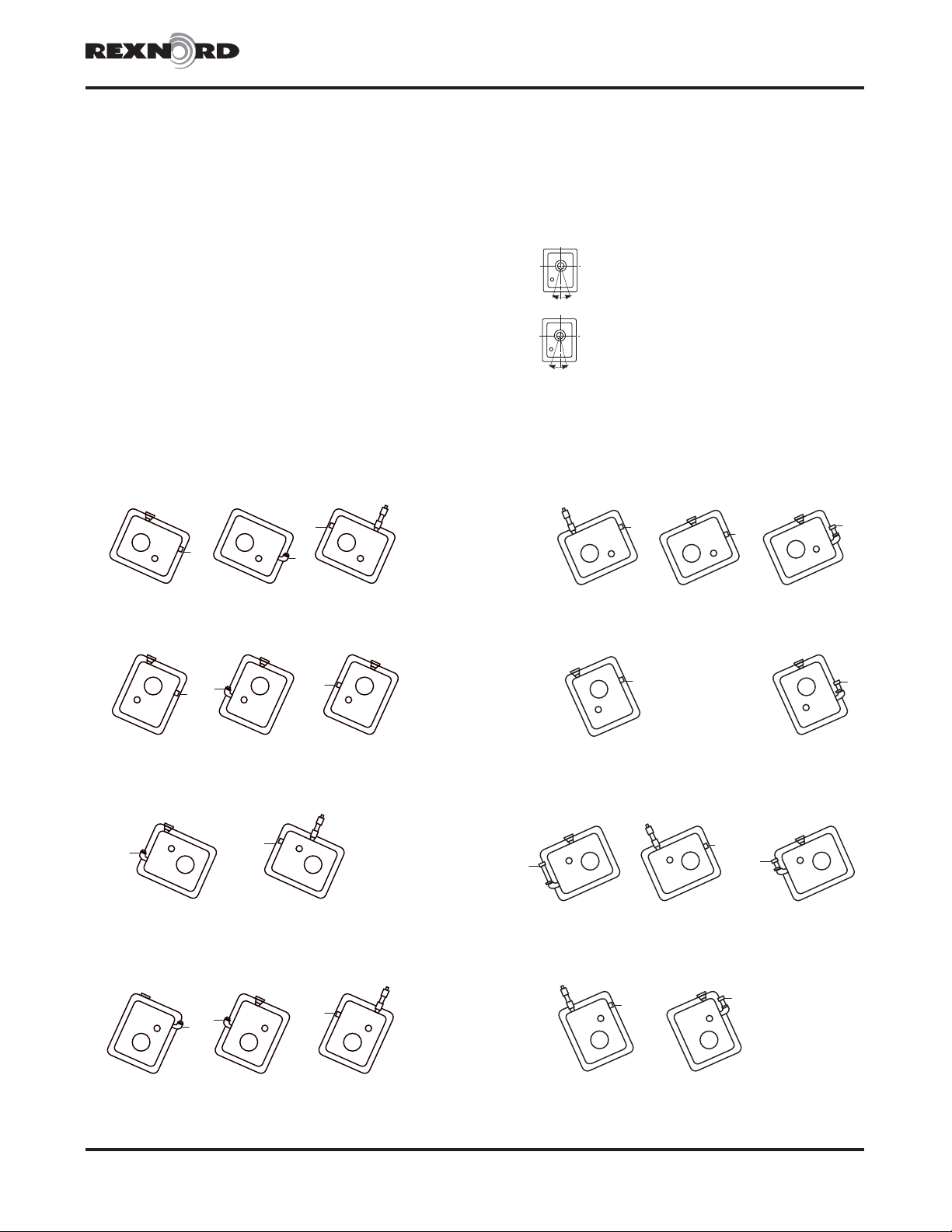

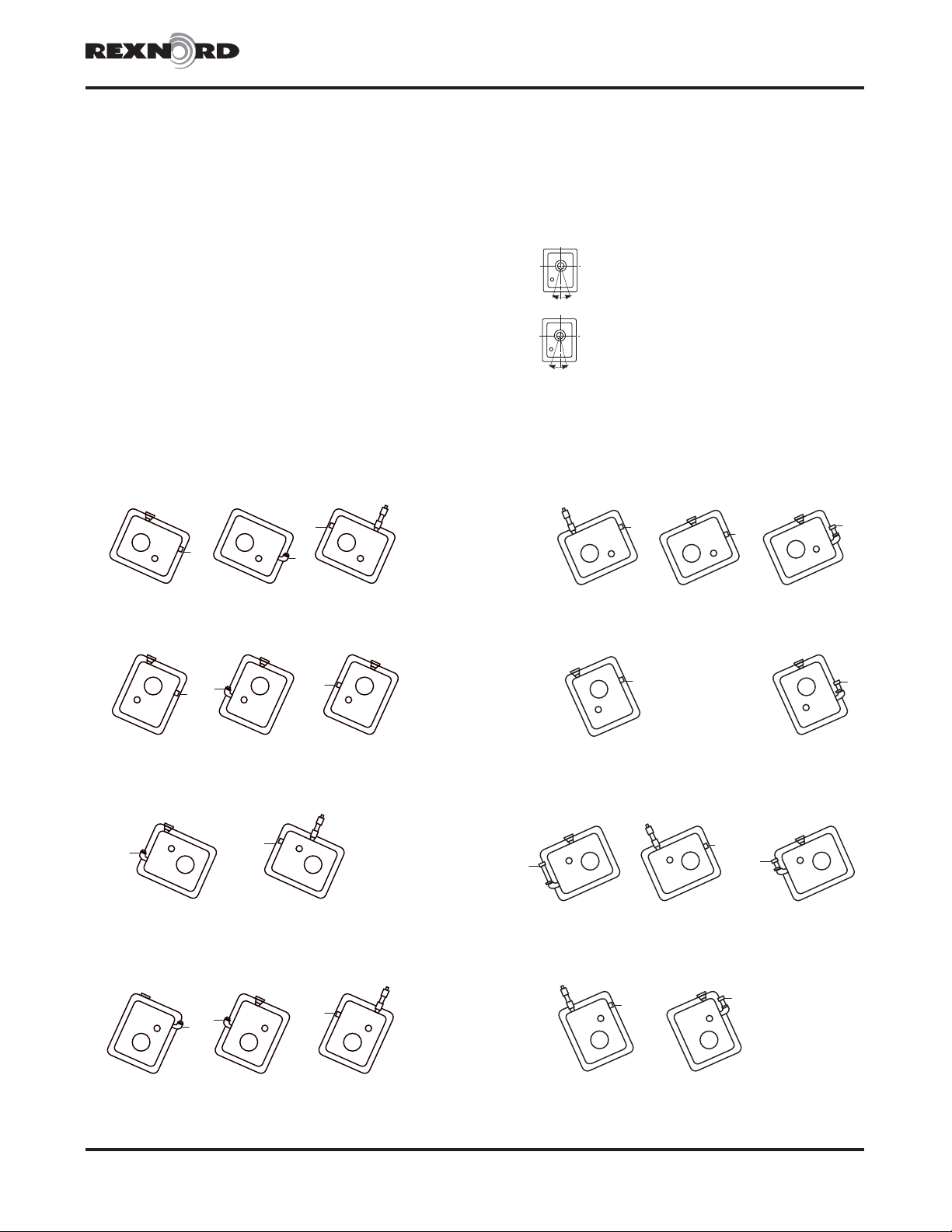

For non-standard mountings, modify drives as illustrated

below and on Page 2 to assure satisfactory lubrication. For

applications that exceed the limits shown, drives that are both

rotated AND tilted and drives with backstops, consult Factory.

CAUTION: Inadequate lubrication will cause damage.

When replacing a pipe plug (P) with a street elbow (E), insert

the plug in the elbow (E/P). When replacing a pipe plug (P)

with a street elbow (E), pipe nipple (N) and a pipe cap (C),

discard the pipe plug. Kits consist of parts for an oil expansion

chamber. Pipe fittings and kits tabulated on Page 2are

available from Rexnord. Pipe fittings may also be purchased

locally. Use galvanized pipe fittings.

Remove all pipe plugs and coat them and the added parts, with

Permatex #3 or equivalent to prevent leakage. Install parts as

illustrated to suit the mounting position. The air vent must be in

the top of the drive or in the kit standpipe. Fill drives with oil to

the level indicated by the letter “L” in the following drawings.

Rexnord Industries, LLC, Gear Group 378-124

3001 W. Canal St., Milwaukee, WI 53208-4200 USA Telephone: 414-342-3131 June 2006

Falk™ Quadrive®Shaft Mtd. Drives Model A •Non-Std. Mounting Installation

Sizes 5107-5315 (Page 1 of 2)

LLL

LL

L

LL

L

L

L

LL

L

LL

L

L

LLL

5107 = STD 5115 = .375 E/P 5203 & 5207 = KIT 0786775

5215 thru 5315 = KIT 0786776

5107 = STD 5115 = .375 E/P 5203 thru 5315 = STD

5107 = 5-12° STD

5107 = 13-20° .375 E/P

5115 = .375 E/P

5203 & 5207 = KIT 0786775

5215 thru 5315 = KIT 0786776

5107 = .375 E/P 5115 = .375 E/P 5203 & 5207 = KIT 0786775

5215 thru 5315 = KIT 0786776

5107 = KIT 0738540 5115 = STD 5203 = .375 E/C & .375 X 1.00N

5207 = .375 E/C & .375 X 2.00N

5215 = .500 E/C & .500 X 2.00N

5307 = .500 E/C & .500 X 2.50N

5315 = .500 E/C & .500 X 2.50N

5107 & 5115 = STD 5203 = .375 E/C & .375 X 1.00N

5207 = .375 E/C & .375 X 1.50N

5215 = .500 E/C & .500 X 1.12N

5307 & 5315 = .500 E/C & .500 X 2.00N

5107 = .375 E/C &

.375 X 3.00N 5115 = KIT 0786775 5203 = .375 E/C & .375 X 1.00N 1.50N

5207 = .375 E/C & .375 X 1.00N 1.50N

5215 = .500 E/C & .500 X 1.12N 1.50N

5307 = .500 E/C & .500 X 1.50N 2.00N

5315 = .500 E/C & .500 X 1.50N 2.00N

5107 & 5115 = KIT 0738540 5203 = .375 E/C & .375 X 1.50N

5207 = .375 E/C & .375 X 2.00N

5215 = .500 E/C & .500 X 2.00N

5307 = .500 E/C & .500 X 2.50N

5315 = .500 E/C & .500 X 2.50N

3 O’Clock — CW Rotation

6 O’Clock — CW Rotation

9 O’Clock — CW Rotation

12 O’Clock — CW Rotation

3 O’Clock — CCW Rotation

6 O’Clock — CCW Rotation

9 O’Clock — CCW Rotation

12 O’Clock — CCW Rotation

5 to 20° CW Rotation – Sizes 5107 & 5115

10 to 20° CW Rotation – Sizes 5203 thru 5315

5 to 20° CCW Rotation – Sizes 5203 thru 5315

10 to 20° CCW Rotation – Sizes 5107 & 5115

Standard Drive Mounting Limits

The standard drive rotation limits from the

basic 3, 6,9&12o’clock mounting

positions are shown at left. For higher limits,

follow the instructions at the left and the

drawings below. (6 o’clock illustrated)

CODE

B — Bushing N — Nipple

C — Cap P — Pipe Plug

E — Street Elbow STD — No Modifications

L — Oil Level

Horizontal Drive Modifications 20° Max. Drive Rotation

10

MAX.

°

5°

MAX.

ROTATION

(4107 & 4115)

5°

MAX.

10°

MAX.

(4203 THRU 4315)

5-15° 16-20°