Falk Quadrive Shaft Mounted Drives Model A • Owners Manual

Sizes 5107-5315 (Page 7 of 52)

Rexnord (PN-2128394) 378-200

3001 W. Canal St., Milwaukee, WI 53208-4200 USA January 2019

Telephone: 414-342-3131 Fax: 414-937-4359 www.rexnord.com Supersedes 04-17

Remove packing rings from the drive shaft and slide

the drive shaft through the seal housing. Install seal

rings into the seal housing. Stagger the seal joints

approximately 90° apart. Slip the compression ring

into place. Use fasteners with flat washers to hold the

ring but DO NOT tighten at this time. Install key in the

drive shaft keyway and then install the drive shaft into

the hollow shaft. Use the thrust plate fastener, Figure

7, to secure the drive shaft. Refer to Table 3 for torque

value. Use the seal housing fasteners to secure the

seal housing to the basic drive. Refer to Table 4 for the

torque value. Reinstall the hollow shaft cover. To adjust

packing seal, rotate input shaft to test the resistance.

Tighten the compression ring fasteners evenly until

an additional resistance can be detected when the

high-speed shaft is rotated. DO NOT OVERTIGHTEN

– this can cause premature seal wear and possible

overheating. Proceed to Step 5.

5. JSC — Fasten the trough end to the seal housing using

the hex head cap screws included in the drive shaft kit.

Refer to Table 4 for torque value. Proceed to Step 7.

6. JF — Install backstops prior to installation of the drive

(refer to Appendix B). If an adapter flange is provided,

assemble it to the drive using fasteners provided with

the flange. Refer to Table 5 for fastener selection and

torque value. Remove the input side hollow shaft cover.

The standard method for connecting a flange-mounted

drive to the driven shaft is to prepare the driven shaft

per Appendix H and mount the drive to the tapered

shaft using a thrust plate kit with fastener as shown in

Table 3. An optional method of connection should be

used when replacing existing drives with special shafts

or when producing tapered shafts is impractical.

This optional method uses a TA tapered bushing as

outlined in Appendix J.

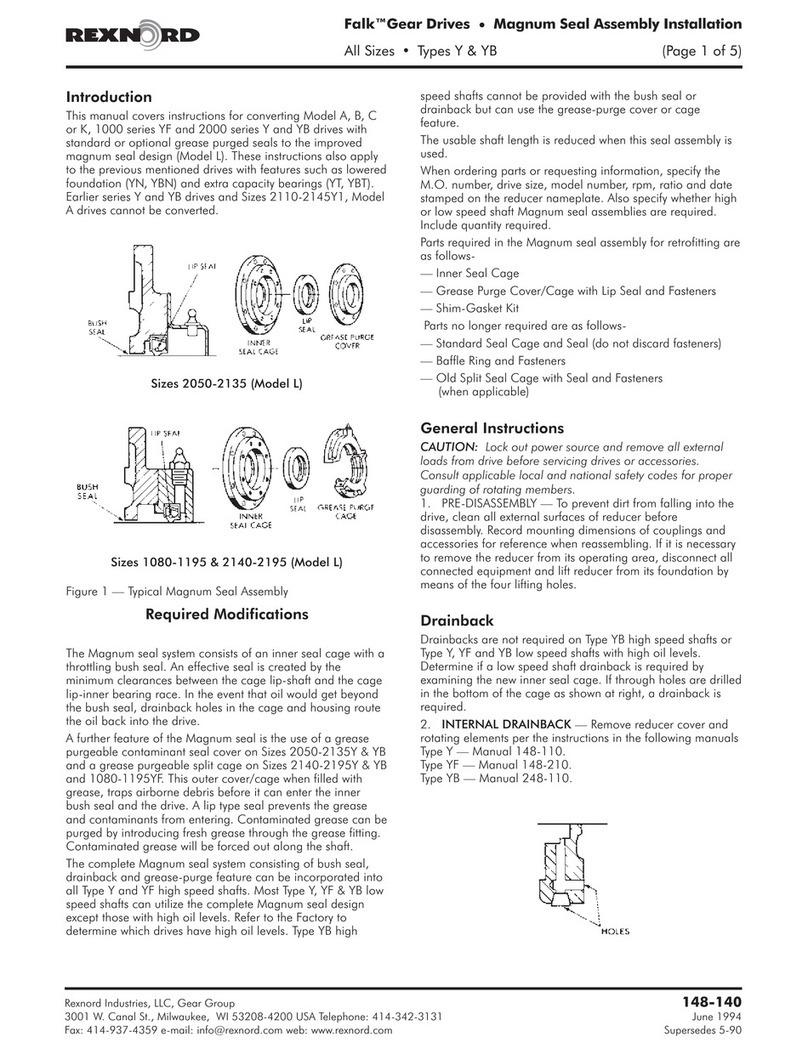

SLING FROM

LONG FASTENER

WITH NUT

SLING AROUND

SEAL HOUSING

ANDINPUT SHAFT

SLING FROM

EYEBOLTS

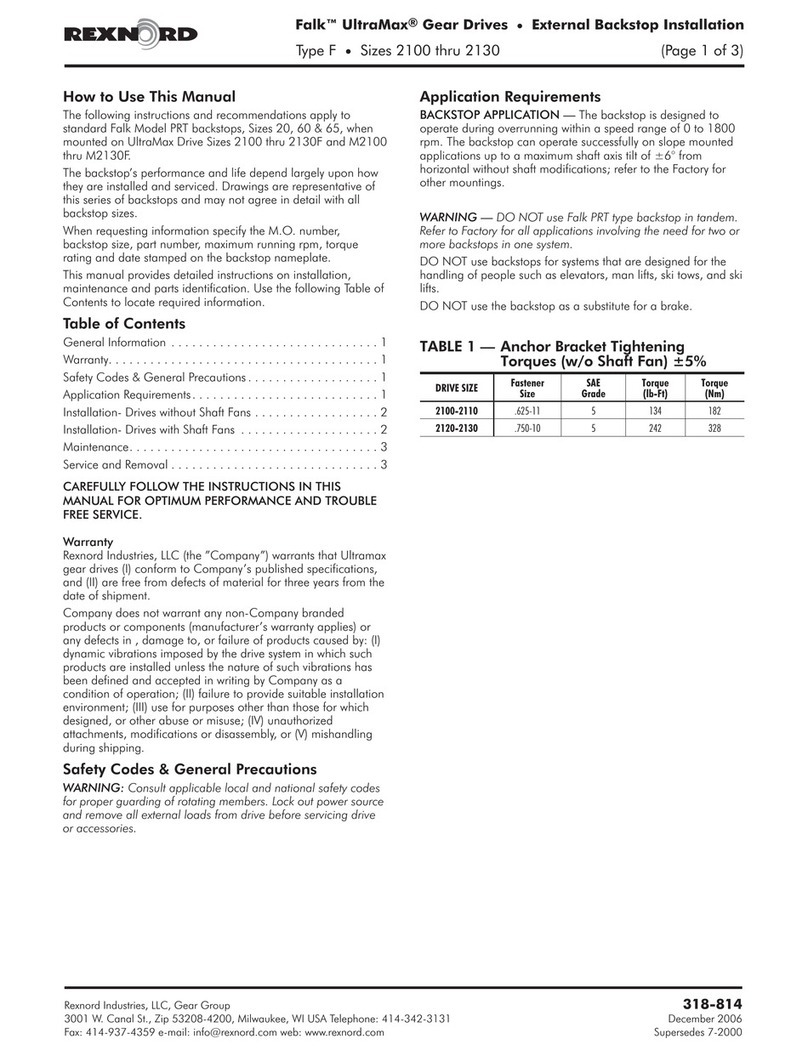

TABLE 5 — Flange-Mounted Drive – Foundation

Fastener Size & Tightening

Torque (Non-Lubricated Fasteners)

DRIVE

SIZE Fastener Size and Grade

Torque

lb-ft

(Nm)

Min Fastener

Engagement

Into Drive

Housing

Inches (mm)

5107 .500-13UNC, GR.5 69 (94) .76 (19.3)

5115 .625-11UNC, GR.5 137 (186) .94 (23.9)

5203 .750-10UNC, GR.5 245 (332) .76 (19.3)

5207 .875-9UNC, GR.5 380 (515) .88 (22.4)

5215 1.000-8UNC, GR.5 567 (769) 1.00 (25.4)

5307 1.000-8UNC, GR.8 792 (1074) 1.24 (31.5)

5315 1.000-8UNC, GR.8 792 (1074) 1.24 (31.5)

INSTALLATION

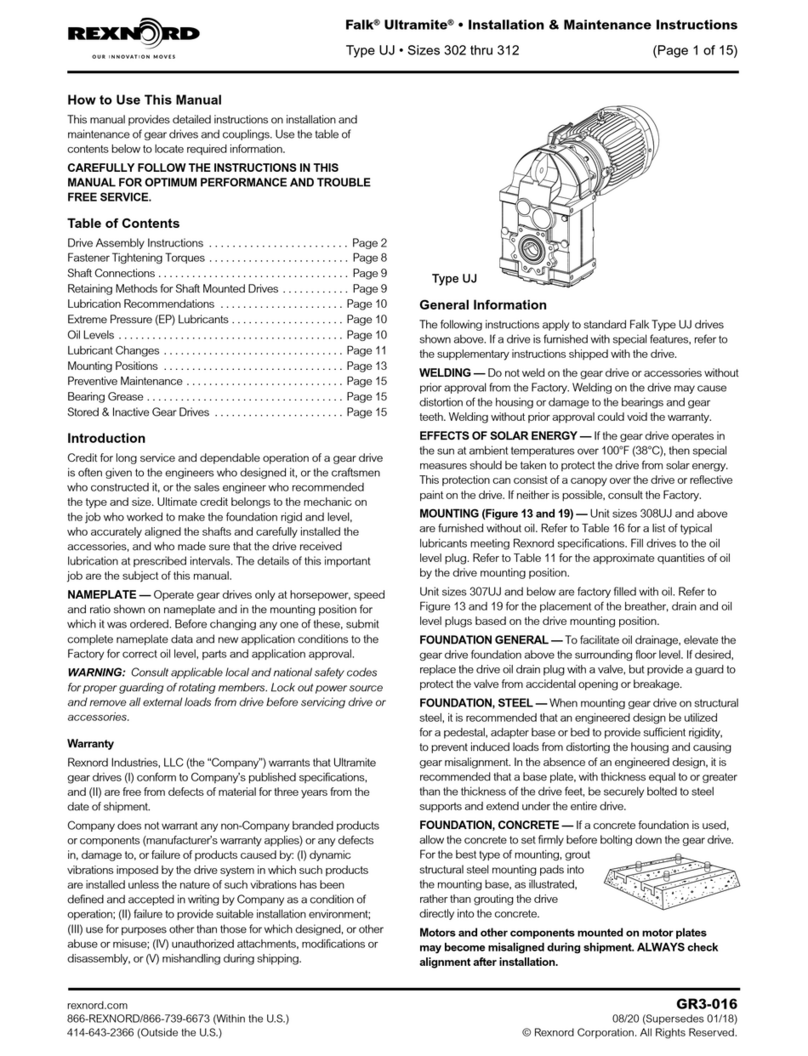

7. JR, JF, & JSC — Refer to Figure 11 for recommended lifting

method. In order to sling JR & JF as illustrated, remove

a housing flange fastener and install a long fastener with

nut. For vertical installation, use (3) eye bolts as illustrated.

Eyebolt sizes are 5/16” for 4107 and 4115, 3/8” for 4203 and

1/2” for 4207 thru 4315. DO NOT remove sling until drive is

secured to shaft. Before lifting the drive into position, rotate

the high-speed shaft until the hollow shaft keyway will be in

position to line-up with the driven shaft key. JF proceed to

Step 12; JSC to Step 13.

8. JR — If the drive was received with a backstop

installed, the backstop must be temporarily removed to

facilitate mounting.

Refer to Section II, Figure 19 and remove cover Ref.

#16 and backstop Ref. #5A1.

9. JR — Lift the drive into position and slide onto the

drive shaft taking care that the driven shaft key seats

into the hollow shaft keyway. DO NOT hammer or use

excessive force. Refer to Figure 12 for installation of

the torque arm. The exact position of the tie rod may

vary within the range shown. For torque arm mountings

other than shown, refer to Rexnord. If it is necessary

to shorten the torque arm, cut the excess from either

threaded end.

The support to which the clevis bracket is to be

fastened must sustain the torque reaction shown

in Table 8. The maximum load reaction through the

torque arm occurs when the torque arm is located

in the extreme (30°) off angle position. Use Grade 5

fasteners to anchor the clevis bracket; see Table 7 for

the fastener diameter and tightening torque.

Bolt the tie rod to both the clevis bracket and the

drive anchor bracket and tighten the bolts until seated

against the brackets. DO NOT bend the bracket as

clearance between the clevis brackets and tie rod is

necessary.

Figure 11