the service life of heating element.

4. This product has a unique active safety protection patent technology, no

spontaneous combustion, no burning handle, fault load automatically cut off,

even in unattended handle do not worry about spontaneous combustion.

5. The product has sound alarm function:

Power-on warning, constant temperature warning, sleep warning, over

temperature warning, no heating failure warning, handle off warning and

other reminders.

1. Remove the device and place it on the work table.

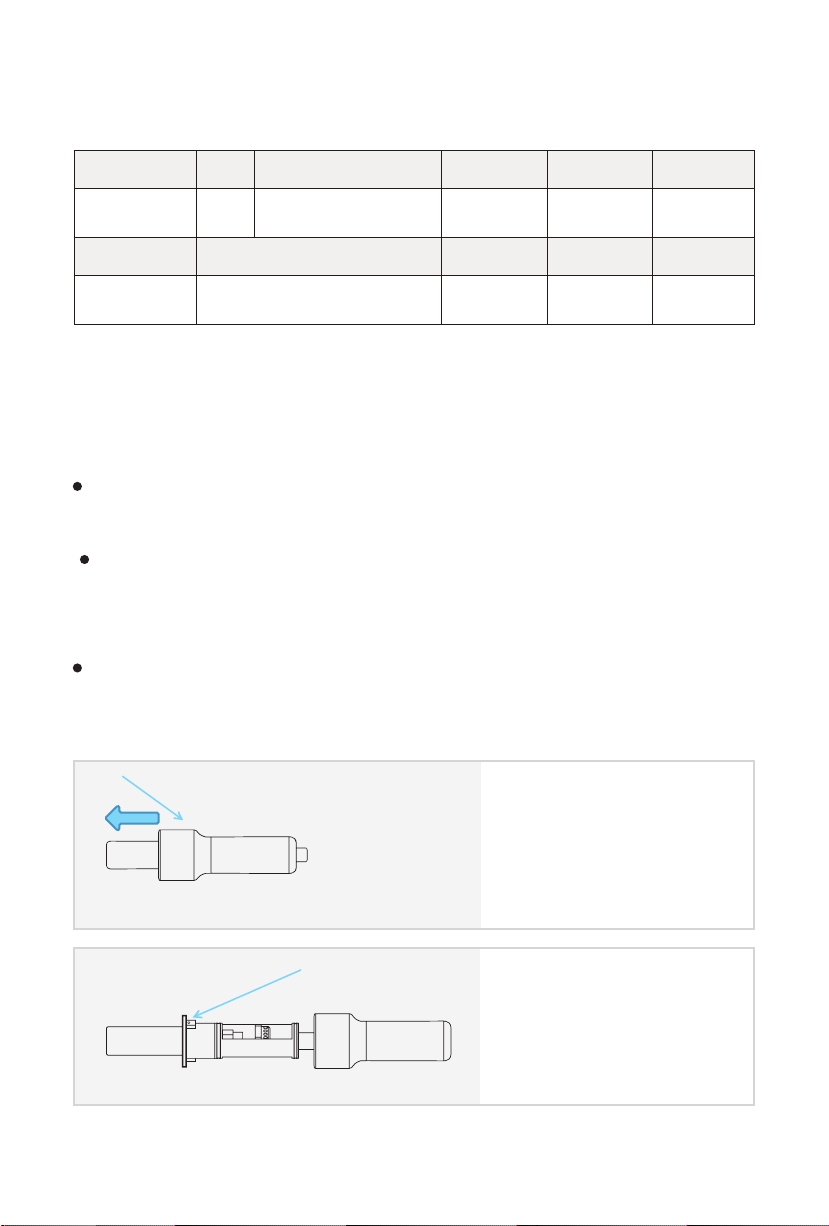

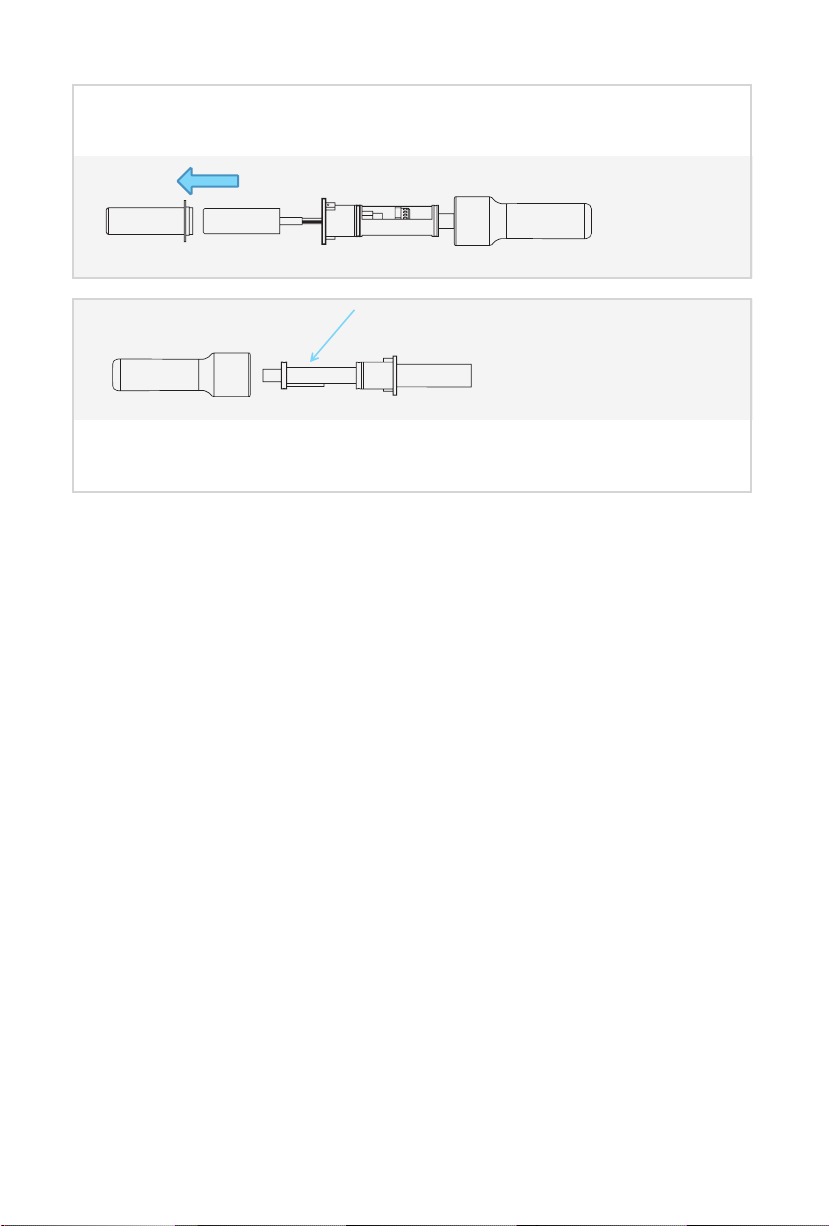

2. Install the air gun nozzle of the required specifications on the steel pipe of

the air outlet of the equipment. After assembling, place the handle on the

handle holder.

3. Connect the AC power cable into the AC seat at the rear of the device to

ensure that the power cable is properly grounded with the device.

4. Turn on the power switch of the equipment, and the display screen shows

"HOT SLEEP".

5. Adjust the "AIR" and "HOT" buttons "▲" and "▼" to achieve the required

AIR volume and temperature.

6. Pick up the handle of the welding table, the welding table is heated

normally. Disassembly and welding can be carried out after the temperature

is constant.

7. After the work is finished, the handle must be placed in the handle frame.

At this time, the welding platform will automatically cut off the power supply

and enter the mode of sending cold air to cool the heating device. When the

temperature is below 70℃, the welding table enters standby mode. At this

time, the fan stops supplying air and the heating wire does not work.

8. Choose two-in-one welding platform, the use of soldering iron is the same,

no longer explain here.

9. The main power switch of the equipment must be turned on and off when

it is not working for a long time.

10. The device has pre-regulated memory working mode: "CH1, CH2, CH3".

You can call the pre-set working channel to work, and you can also pre-set

the selected channel "temperature" and "fan flow".

The default operating mode is the current operating mode. If you need

to invoke any working mode of CH1, CH2, or CH3, press the button once to

check whether the required working mode is available. Press the button

again to invoke the parameters of the current channel. When you view a

channel, the channel number is displayed on the right of the screen.

Save working mode: In the current working mode, double click the key

corresponding to the channel to save.

IV . Operation instructions