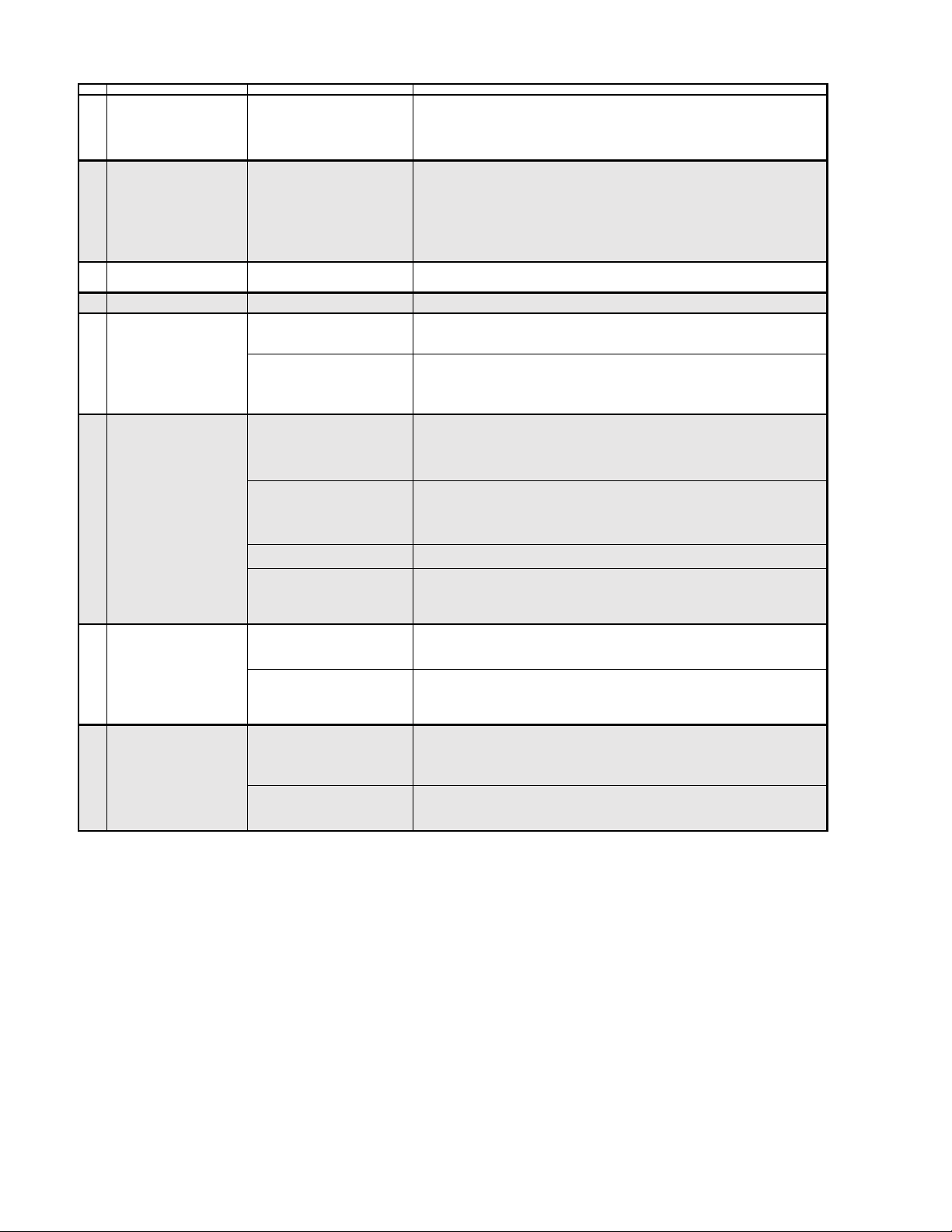

# Remedy

Closedoortothebox.Makesuredoorremainsclosedunless/untilaccesstoboxisneeded.

Verifyatcontrollerdisplaythecurrentsuperheatandvalveposition;goto Status →Superheat/EXVCurrentPos. Ifsuperheatis

consistentlyhighandvalveisconsistentlyrunningatorcloseto100%,thesystemcouldbelowonrefrigerant.Verifyifsight

glassatcondensingunitisclear.Verifysuctionpressurewithasetofgauges.Rechargesystemasneeded,verifyifanyleaksare

presentandfixasneeded.

Verifyatcondensingunitifcompressorisshuttingdownintermittently.Troubleshootcondensingunitandverifyifhighhead

pressure,phaseloss,etc.

Verifyunderthecontrollersettingsthatthecorrectrefrigerantisselected.Onthedisplay,goto

Settings →Equipment→Refrigerant .Anincorrectrefrigerantsettingwillcauseincorrectsuperheatcalculationandthesystem

willnotoperateproperly.

VerifyifSuctionTempThermistoralarmisactive:oncontrollerdisplaygoto Service →CurrentAlarms .AlsoverifySuction

TemperaturereadingunderStatus→Sensors→SuconTemp ;ifitisreading"‐60 ⁰F",thesensorisnotmakinggoodcontactoris

missing.IfSuctionTempsensorinputismissing,theEXVwillremainatafixedpositionuntilsensorisreplaced,andalarm

"A100SuctionTempThermistorFailure" willbeactive.Ifsensorisreadingavalueotherthan‐60 ⁰F,verifythatitisnotan

erraticvalueandthatthereadingreasonablycorrespondstotheconditionsattheevaporator(forexample,ifsensorisreading

150⁰Fwhenthesuctionlineattheevaporatorisnearfreezingconditions). ReplaceSuctionTempThermistor(partno.

08219637).

VerifyifSuctionPressurealarmisactive:oncontrollerdisplaygoto Service →CurrentAlarms .AlsoverifySuctionPressure

readingunderStatus→Sensors→SuconPressure ;ifitisreading"‐14.7PSIG",thesensorismalfunctioningorisdisconnected.

Ifthecontrollerdetectsthatthepressureinputismissing,alarm "A106SuctionPressureSensorFailure" willbeactiveandthe

controllerwillattempttocalculateapproximatesuperheatbyusingEvapTemp1readinginsteadofSaturatedSuctionTempand

continuemeteringtheEXV,butthecalculatedsuperheatwillnotbeasaccurate. ReplaceSuctionPressureTransducer(partno.

08219621).

VerifyharnessconnectiontotheEXVandtothecontrollerboardissecure.SetSystemEnabletoNO,under Settings →System

Enable inordertoclosetheEXVandforceapumpdown.ConfirmthattheEXVcanbeheardmovingasitcloses.ConfirmEXV

positionunderStatus→EXV→EXVCurrentPos. is0%.Verifythatcompressorpumpsdownandshutsoffafteracoupleof

minutes;SuctionPressurereadingunderStatus→Sensors→SuconPressure shoulddecreaseasthesystempumpsdown.If

thecompressorisstillrunninganddoesnotturnoff,theEXVmaybemalfunctioningandallowingsomerefrigeranttopass

throughevenafterbeingcommandedbythecontrollertoclose. SeeAddendumAformoreinformationontroubleshootingthe

EXV.ReplaceEXVifnecessary.

Makesuredoortothefreezeriskeptclosedunless/untilaccesstofreezerisneeded.

Verifythatwhencontrollerstartsadefrost,theheatersareenergizedandoperatingproperly.Amanualdefrostcanbestarted

bygoingonthedisplaytoService →DefrostControl→StartaDefrost .VerifyatthecontrollerboardthattheLED'sforthe

defrostrelaysturnONandtheirstatusisONonthedisplay( Status→Outptus→DefrostRelay#1/#2 ).IftheunitisaLow

Profileevaporator,makesurethatCoilTypeissetto"Single" (gotoSettings→Equipment andscrolldowntoverifythese

parameters),andthatEvapTemp1sensorisconnectedandhavingavalidreading.IfEvapTemp1sensorisdisconnected,the

controllerwillalarm( "A101EvaporatorTempSensorFailure" )andtheDefrostRelayswillnotturnON.IfCoilTypeis

mistakenlysettoDual,thecontrollerwillalarm( "A102EvapTemp2ThermistorFailure" )andthemissingEvapTemp2sensor

willpreventDefrostRelay#2fromturningon;thiswouldkeepthebottomheateranddrainpanheaterfromturningonduringa

defrostandwillcauseicebuilduponthebottompartofthecoil.IfbothDefrostRelaysareturningON,verifywithameterthat

theheatersaredrawingampsandarewarmingup;iftheyarenot,verifytheheaterwiringwiththewiringdiagramatthe

evaporator.Iftheheatersarewiredproperlybutstillnotheating,theymayneedtobereplaced.

Iftheheatersareverifiedtobeworkingproperly,proceedtoverifydefrostcycleduration:onthecontrollerdisplay,goto

Status →Defrost→LastDefr.Time .Also,forceadefrostandwaitforittofinishtotakenoteoftheduration.LowProfile

Evaporatorstypicallyneedbetween20to30minutesdefrostdurationtocleartheice.Ifthedefrostcycleistooshort,the

DefrostTerminationTemperature(Def.Term.Temp )andRuntimeUntilDefrost( Def.Cmp.RunTime )canbeadjustedas

neededinSettings→Equipment .Also,thepulsingonDefrostRelay#1(topheater)canbedisabledbysetting DefrostPulse

Override toYESifneeded.Iftheunitalreadyhassomeicebuiltupinthecoil,itmaytakeseveraldefrostcyclestocleartheice

aftertheparametersmentionedaboveareadjusted.

Makesuredoortothefreezeriskeptclosedunless/untilaccesstofreezerisneeded.

Verifythatwhencontrollerstartsadefrost,theheatersareenergizedandoperatingproperly.Amanualdefrostcanbestarted

bygoingonthedisplaytoService →DefrostControl→StartaDefrost .VerifyonthecontrollerboardthattheLED'sforthe

defrostrelaysturnONandtheirstatusisONonthedisplay( Status→Outptus→DefrostRelay#1/#2 ).IftheunitisaCenter

Mountevaporator,makesurethatCoilType issetto"Dual" andDefrostPulseOverride setto"YES" (goto

Settings→Equipment andscrolldowntoverifytheseparameters),andthatEvapTemp1andEvapTemp2sensorsare

connectedandhavingavalidreading.IfEvapTemp1sensorisdisconnected,thecontrollerwillalarm( "A101EvaporatorTemp

SensorFailure" )andDefrostRelay#1willnotturnON;ifEvapTemp2sensorisdisconnected,thecontrollerwilalarm( "A102

EvapTemp2ThermistorFailure" )andDefrostRelay#2willnotturnON.IftheDefrostRelaysareturningON,verifywitha

meterthattheheatersaredrawingampsandarewarmingup;iftheyarenot,verifytheheaterwiringwiththewiringdiagram

attheevaporator.Iftheheatersarewiredproperlybutstillnotheating,theymayneedtobereplaced.

OnCenterMountevaporators(CoilType=Dual ),bothEvapTemp1(whitewires)andEvapTemp2(bluewires)areusedfor

defrosttermination.Duringadefrostcycle,whenEvapTemp1sensorreachesDefrostTerminationTemp,theDefrostRelay#1

willturnoff.SameforEvapTemp2withDefrostRelay#2;eachsidewillterminatedefrostindependently.Verifywiththe

wiringdiagramontheunitthatEvapTemp1sensorislocatedonthecoilwhoseheatersarewiredtoDefrostRelay#1.Same

goesforEvapTemp2,itshouldbelocatedonthecoilwhoseheatersarewiredtoDefrostRelay#2.

OnCenterMountevaporators(CoilType=Dual ),makesurethatDefrostPulseOverrideissettoYESsoDefrostRelay#1does

notpulseduringadefrostcycle(goto Settings →Equipment→Def.PulseOverr. andmakesureitissettoYES).

Iftheheatersareverifiedtobeworkingproperly,proceedtoverifydefrostcycleduration:onthecontrollerdisplay,goto

Status →Defrost→LastDefr.Time .Also,forceadefrostandwaitforittofinishtotakenoteoftheduration.CenterMount

Evaporatorstypicallyneedbetween20to30minutesdefrostdurationtocleartheice.Ifthedefrostcycleistooshort,the

DefrostTerminationTemperature(Def.Term.Temp )andRuntimeUntilDefrost(Def.Cmp.RunTime )canbeadjustedas

neededinSettings→Equipment .Iftheunitalreadyhassomeicebuiltupinthecoil,itmaytakeseveraldefrostcyclestoclear

theiceaftertheparametersmentionedaboveareadjusted.

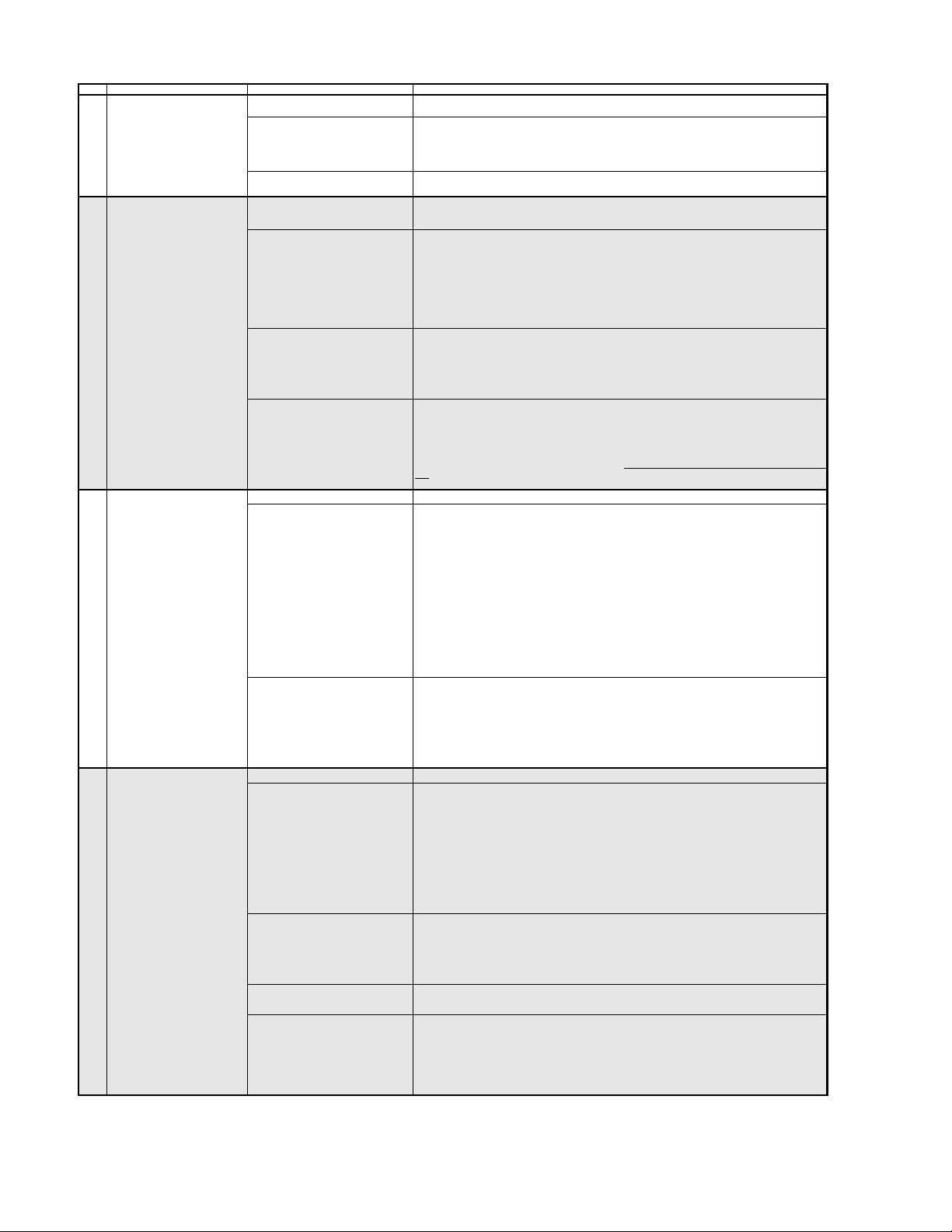

Compressorcouldbeshuttingdown

intermittently.

Verifythatthecorrectrefrigerantisselected.

Doorisopen.

SuctionTempsensordisconnected(controllerwill

alarm;redLEDoncontrollerwillbeblinking),or

sensorcouldbemalfunctioning/readingerratic

value.

SuctionPressuretransducerdisconnected

(controllerwillalarm;redLEDoncontrollerwillbe

blinking),ortransducercouldbemalfunctioning.

9

10 Suctionlineatcompressorisicingup

excessively.

Systemcouldbeundercharged/leakpresentinthe

system.

12 Evaporatorcoilisicingup(CenterMount

FREEZER,electricdefrost).

UnitiscoolingbutSpaceTempnever

reachessetpoint.

Verifythatheatersareworkingwhencontroller

goesintodefrost.

Verifydurationofdefrostcycle/runtimebetween

defrosts.

Doorisbeingleftopen.

11 Evaporatorcoilisicingup(LowProfile

FREEZER,electricdefrost)

VerifyEXVisfunctioningproperly,closing

completelyforpumpdown.

VerifyEvapTemp1andEvapTemp2sensor

locations.

VerifyDefrostPulseOverrideissettoYES.

Doorisbeingleftopen.

Verifythatheatersareworkingwhencontroller

goesintodefrost.

Verifydurationofdefrostcycle/runtimebetween

defrosts.

Problem PossibleCause

Page2of4