EON Field Replacement Kit

EON Control for Replacing ECM 2.3 or EON motor Control

This control cannot be used on ECM2.0 motors. For ECM2.0

motors replace entire motor with specified Eon Motor/module

assembly.

NOTE: Read the entire instruction manual before starting the

installation.

SAFETY CONSIDERATIONS

ENERAL WARNIN S

Installing and servicing of heating and air conditioning

equipment can be hazardous due to gas, system pressures, and

electrical components. Only trained personnel should install or

service heating and air conditioning equipment. The qualified

installer or agency must use factory authorized kits or

accessories when modifying this product. Refer to individual

instructions packaged with kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves.

Have a fire extinguisher available. Read these instructions

thoroughly and follow all warning or cautions attached to the

unit. Consult local building codes and National Electrical Code

(NEC) for special requirements. Recognize safety information.

This is the safety-alert symbol When you see this symbol

on the unit and in the instructions or manuals, be alert to the

potential for personal injury.

WARNING ELECTRICAL SHOCK AND

NATURAL GAS EX OSURE

Before installing or servicing unit, always turn off all gas and

electrical supplies to unit. There may be more than one

disconnect switch. Turn off accessory heater power if

applicable. Electrical shock can cause personal injury or death.

WARNING RO ER TOOLS AND

SKILLS

The ability to properly perform service on this equipment

requires certain expertise, mechanical skills, tools, and

equipment. If you do not possess these, do not attempt to

perform any service on this equipment other than those

procedures recommended in the User’s Manual. A failure to

follow this warning could result in possible damage to this

equipment, serious personal injury, or death.

WARNING ELECTRICAL SHOCK

Wait at least 5 minutes after disconnecting line voltage from

equipment before opening motor to prevent electric shock which

can cause personal injury or death.

CAUTION FAILURE MAY RESULT

Installing connectors incorrectly may result in immediate failure

of control module.

Included: EON Control

Two 2.45-inch Bolts

Two 2.76-inch Bolts

Adapter Ring

Instructions:

Before you begin, verify control is non-functional using unit

troubleshooting instructions. See below for instructions.

1. Disconnect main power. Detach 5-pin power cable and

16- pin signal cable from the existing control.

2. Determine motor type by comparison to Figures 1a and 1b.

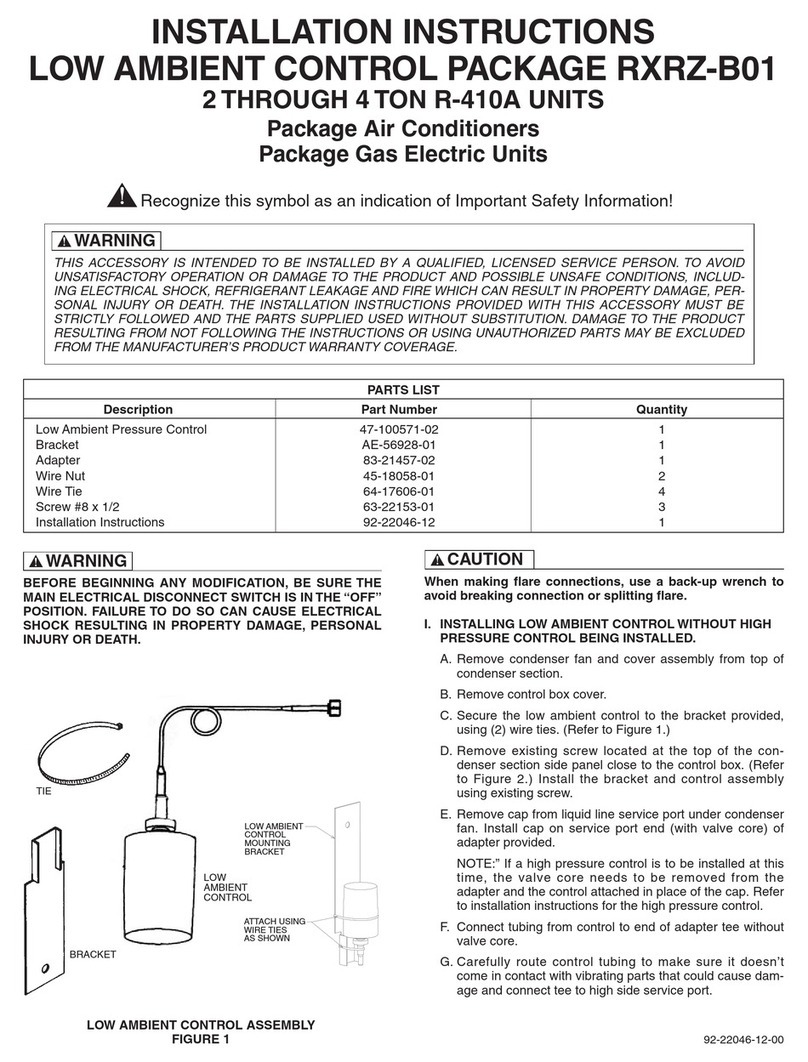

Figure 1a: Figure 1b:

EON connector ECM 2.3 connector

3. Wait at least 5 minutes to remove the

installed control. Unscrew and remove 2 bolts from the end

of the installed control attaching it to the motor. Separate the