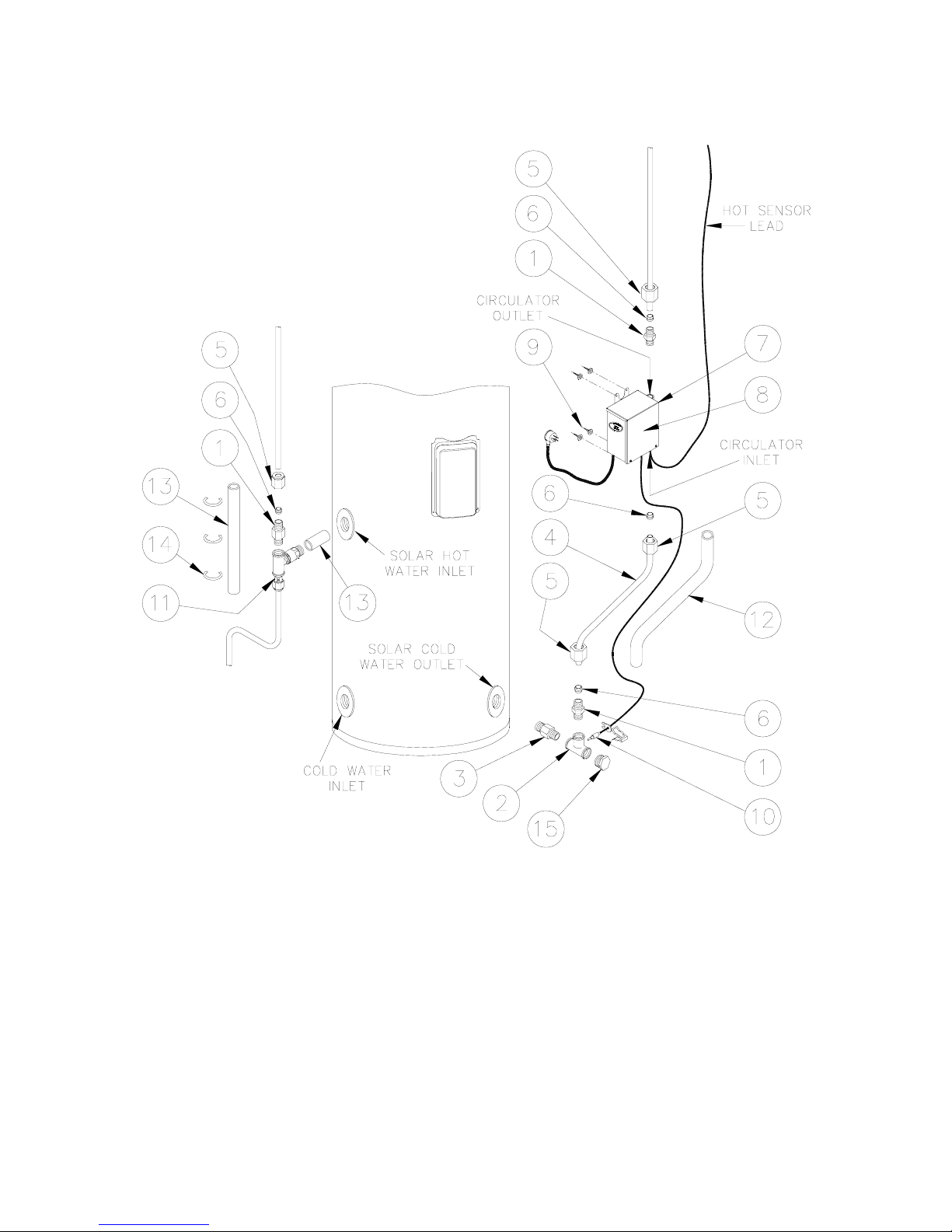

INSTALLATION – SOLAR CONTROL UNIT

The solar control unit is designed to be mounted on the side of the solar

storage tank, with its location above and offset from the solar cold water outlet.

The solar control unit, supplied with a 1.8 metre power cord, requires a 240 V

50 Hz general purpose outlet (GPO) located within 1.2 metres of its installation.

The GPO must have a continuous power supply originating from a circuit other

than the water heater circuit. The GPO is required to be weatherproof if

installed outdoors (refer to “Connections – Electrical” on page 8).

Part No Kit Components and Description - Controller Kit 299121

126554 Installation instructions solar controller kit 1

052104 Control unit solar pumped assembly 1

220342 Valve assembly air bleed and check

consisting of:

1 x 088058 fitting tee brass ½” screwed Rye 4203

1 x 088071 solar non return valve RMC ½” x ¾” SNR502

1 x 088069 fitting adaptor brass 1” F x ½” M

1 x 220340 air bleed ball valve

1 x 080123 washer 30 OD x 20 ID x 2 Salmson

1

088064 Sensor tee / nipple assembly solar pumped

consisting of:

1 x 088061 tee 3 way / cold sensor

1 x 088062 sensor nipple – solar pumped

1 x 087026 O ring 5/16” ID x 1/16” BS011 silicone

1

223603 Pipe preformed tube ½” x 240 mm long 1

080031 Screws No 8 x 13 mm 4

088063 Fitting union male ½” x ½” Rye 4910 3

088039 Fitting nipple brass ¾” x ½” 1

080079 Plug ½” BSP brass 1

Cable tie black 150 mm x 3 mm 3

Insulation pipe 12 mm ID x 280 mm long 1

Insulation pipe 35 mm ID x 150 mm long 1

Insulation pipe 35 mm ID x 50 mm long 1

Notes:

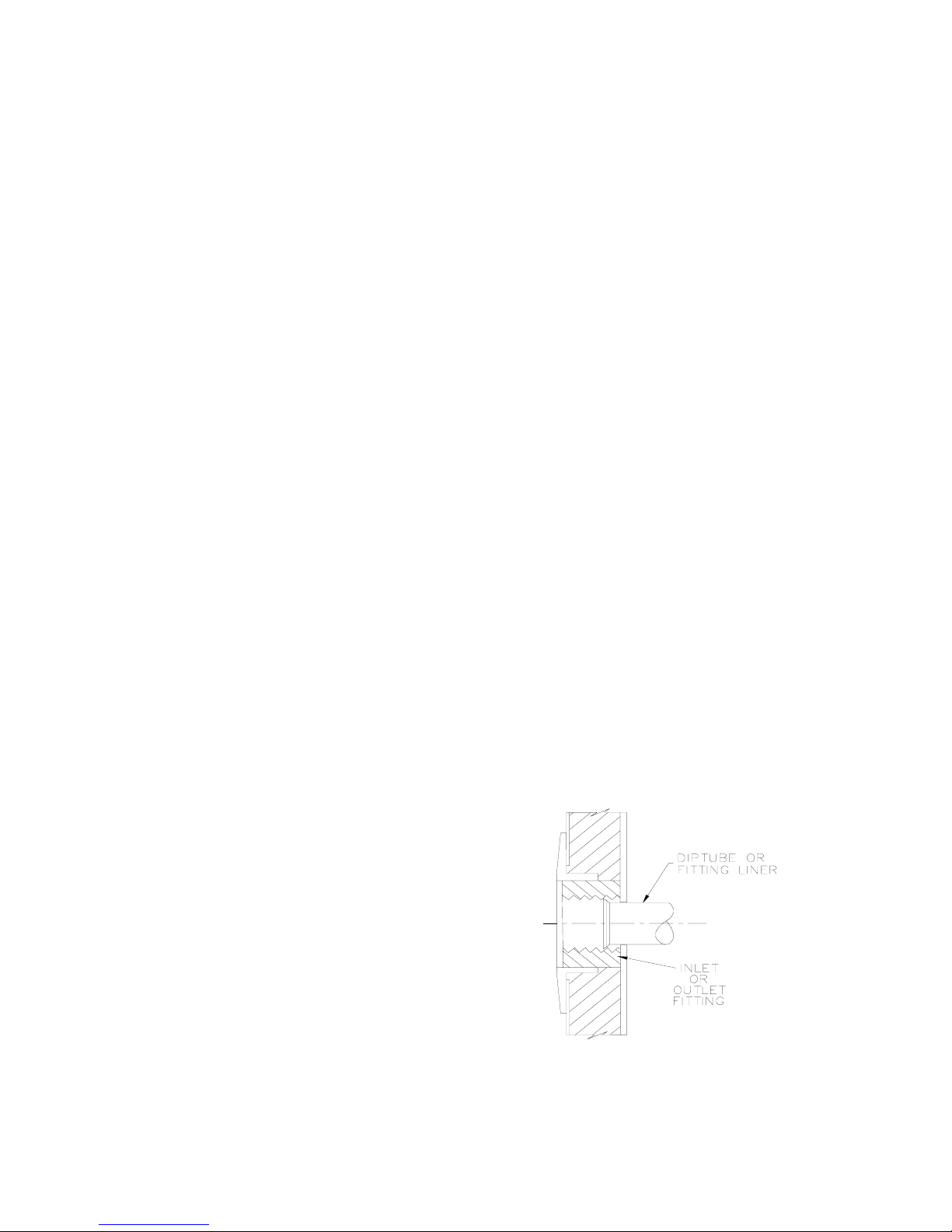

•Care must be taken when mounting the solar control unit to the side of the

solar storage tank. Damage to the cylinder as a result of mounting the solar

control unit to the jacket will void the warranty (refer to “Saddling - Pipe

Work” on page 7).

•Use thread sealing tape or an approved thread sealant on all fittings.

2