flushing.

6.0 OPERATION

6.1 INJECTIONS (MODEL 7010 ONLY)

Before connecting the column to the

injector, flush the injector with mobile phase

in both the LOAD and INJECT positions.

After flushing the injector, turn to LOAD,

and connect the column.

6.1.1 LOADING THE SAMPLE LOOP

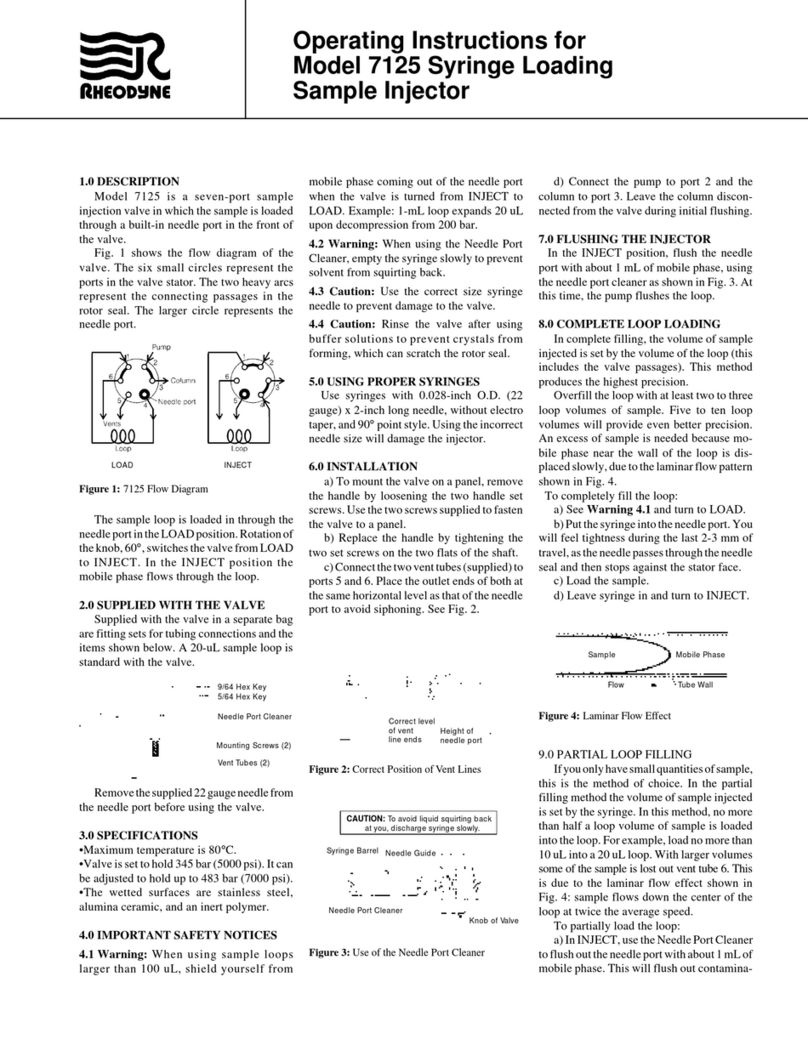

Overfill the loop with at least two to five

loop volumes of sample. Six to ten loop

volumes will provide even better precision.

An excess of sample is needed because

mobile phase near the wall of the loop is

displaced slowly due to the laminar flow

effect shown in Figure 2.

To completely fill the loop (see Figure 3):

a) See Warning 4.1 and turn to LOAD.

b) Insert the syringe into the accessory

injection port.

c) Load the sample.

d) Leave the syringe in position and turn to

INJECT.

6.2 SUGGESTED APPLICATIONS FOR

SWITCHING VALVES

Flush the valve with mobile phase before

connecting the valve to system components.

Suggested applications for switching valve

applications are shown in Figures 7, 8, 9, and

10.

7.0 ADJUSTING FOR LEAKAGE OR

HIGHER PRESSURE OPERATION

The three small set screws in the stator (see

Figure 4) have been factory set so that when

the three stator screws are fully tightened, the

spring force between the valve rotor and

stator is sufficient to hold the indicated

pressure. If leakage is to be corrected, or if

operation at a higher pressure is to be done,

proceed as follows: The three set screws

should be loosened about 1/20 turn each (18°

of rotation) and the three stator screws

tightened an equal amount. If this new

setting fails to accomplish leak-free

operation at the desired pressure, repeat the

procedure by an additional 1/20 turn. Avoid

excessive tightening which will only

increase wear of the rotor seal. If it is

necessary to loosen spring tension, either to

lower the operating pressure, or to adjust for

a new rotor seal, which may be thicker than

the one being replaced, reverse the above

procedures. For example, first loosen the

stator screws, then tighten the set screws.

If leakage cannot be stopped by tightening

the valve, or if, as a result of tightening to

stop the leakage, the handle is too hard to

turn, the rotor seal needs replacing. See next

section.

8.0 MAINTENANCE

The only parts that may need eventual

replacement are the rotor seal and isolation

seal. Abrasive particles in the sample can

damage the rotor seal.

Genuine Rheodyne parts are easily replaced

by the following instructions.

8.1 DISASSEMBLY

To disassemble the valve, refer to Figure 4

and proceed as follows:

a) Remove the three stator screws.

b)Remove stator and stator ring from

valve body.

c) Pull the rotor seal off of the pins.

d)Remove the isolation seal.

8.2 REASSEMBLY

8.2.1 TWO-POSITION VALVE REASSEMBLY

To reassemble Models 7010, 7000, 7030,

and 7040, refer to Figures 4 and 6 and

proceed as follows:

a) Mount the new isolation seal onto the

shaft with the open side facing the handle.

b) Be sure that the rotor seal is correctly

oriented as shown in Figure 6 with rotor seal

grooves facing the stator and with the notch

in the metal rim of the rotor seal in line as

shown (the notch also faces the stator).

c) In replacing the stator ring, be sure that

the two stop pins are still in their holes in the

stator ring, then push the stator ring squarely

onto the shaft assembly allowing the stop

pins to enter the mating holes in the body. Be

sure the rotor pin is located between the two

stop pins (Model 7060 does not have a rotor

pin so the rotor can be in any position).

d) Replace the stator by first pushing it

onto the two pins on the stator ring and then

adding the three stator screws. Tighten each

screw a little at a time to keep the stator

surface parallel to the stator ring surface. If

the three set screws in the stator were left

unchanged, tighten the three stator screws a

1/2 turn past fingertight. The three set screws

will ensure that the gap between stator and

stator ring is uniform and in the original

position before disassembly.

e) If the set screws need adjusting because

a new rotor seal was installed or because

leakage has to be stopped, each set screw

should be turned an equal amount to ensure

that after the stator screws are retightened,

the gap between the stator and stator ring is

uniform all around. Refer also to Section 7.0.

8.2.2 MODEL 7060 REASSEMBLY

An arrow has been engraved on the knob

end of the shaft. Orient the rotor seal on the

rotor as shown in Figure 6 relative to this

arrow (with the grooves in the rotor seal

facing the stator).

Follow the steps in Section 8.2.1.

8.3 ATTACHING HANDLE

The knob for the Model 7060 has a single

set screw located opposite the black handle.

The knob should be oriented on the Model

7060 shaft so that the knob pointer points in

the same direction as the arrow on the end

of the shaft. The set screw should be

tightened on the flat of the shaft with the tip

of the set screw centered on the hole in the

shaft. Confirm this centering before final

tightening of the set screw.

The knob for the two-position valves has

two set screws, both at 90° from the black

handle. It is best to tighten only the one set

screw on the flat of the shaft although both

set screws can be tightened. Confirm that

the set screw tip is centered on the hole in

the shaft before tightening (remove one set

screw to observe alignment while tightening

the other).

Fig. 2. Laminar flow effect.