d) Remove the two hex screws in the stator

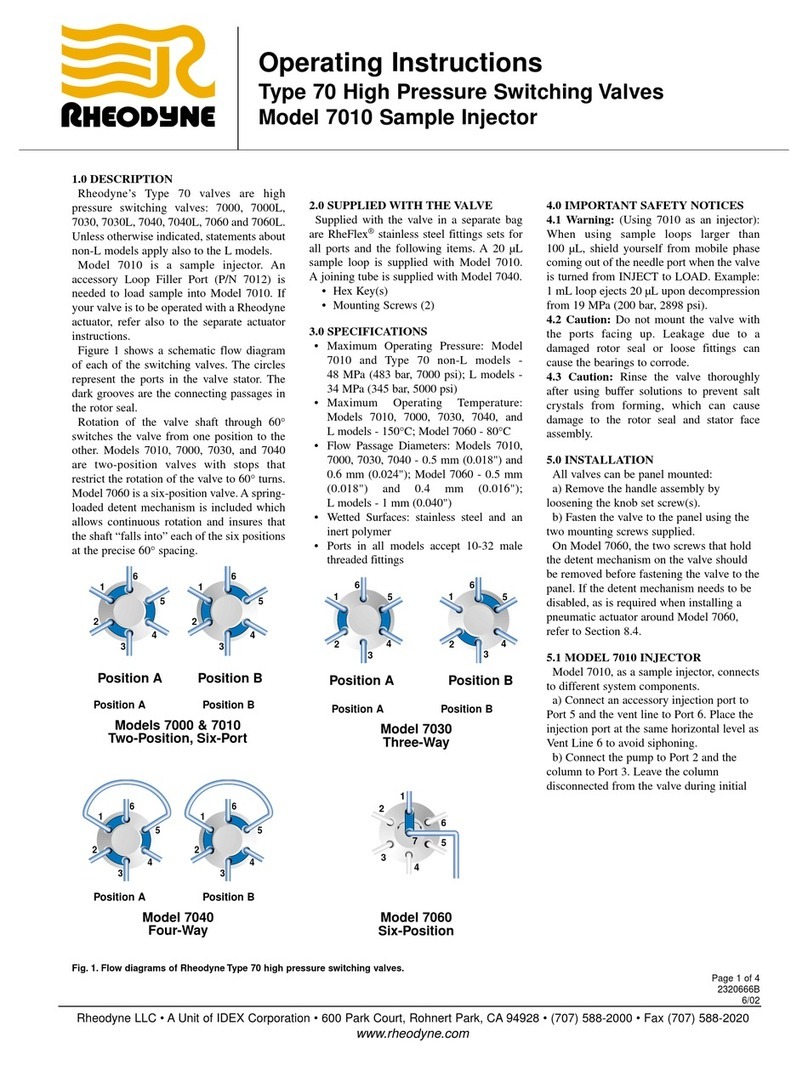

ring. To make it easier to pull the stator ring

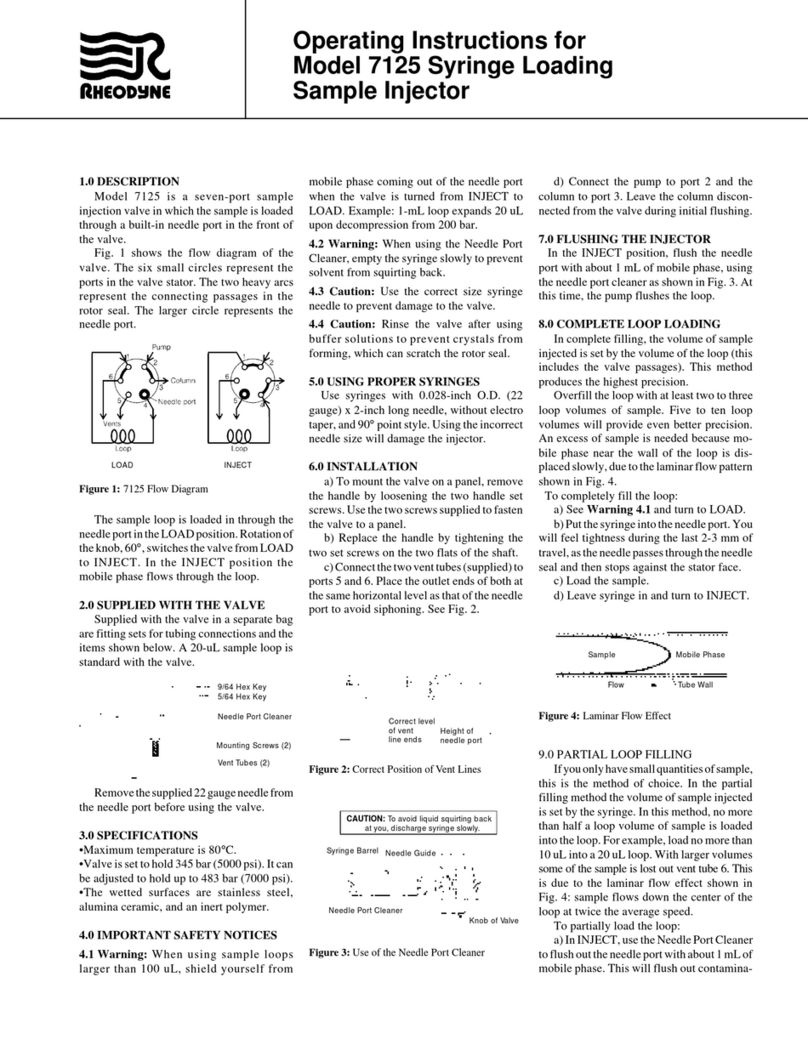

off, screw the two hex screws into two of the

three stator screw holes. Take the stator ring

off by pulling on the two hex screws while

rocking the stator ring back and forth (see

Figure 13). Pull the rotor seal off the four

pins.

Note: If the shaft assembly comes out with

the stator ring, ensure that the gear goes back

into the actuator body and lines up correctly

with the two racks on either side. The racks

can be moved up and down to align the

punch marks on the racks with the punch

marks on the gear (see Figure 14).

e) Remove the isolation seal (it may have

come off with the stator ring).

9.2.2 REASSEMBLY

To reassemble Model 8126, refer to Figures

11, 12, 13, and 14 and proceed as follows:

a) Mount the new isolation seal with the

open side facing the handle.

b) Line up the new rotor seal as shown in

Figure 11. The rotor seal grooves face the

stator. The notch on the rotor seal's metal

band is at 12 o'clock.

c) Replace the stator ring so that the two

pins in the stator ring enter the mating holes

in the actuator body. The two drain slots on

the stator ring must be in the down position.

Replace the two hex screws in the stator ring.

d) Follow steps d-g from Section 9.1.2.

9.3 POSITION SENSING SWITCH IN

MODEL 8125

The position sensing switch is standard in

Model 8125. The switch is a magnetic reed

switch actuated by a magnet sealed inside the

shaft. The switch is rated for 100 V at 200

mA.

To replace or remove the switch:

a) Remove the handle assembly.

b) Remove the three stator screws.

c) Remove the stator, stator ring, and stop

ring.

d) Pull the switch out of the stop ring.

e) Replace with new switch, or leave the

hole empty if the switch is not needed.

f) Follow the steps in Section 9.1.2 to

reassemble.

10.0 OPERATING SUGGESTIONS AND

TROUBLESHOOTING

10.1 LEAKAGE

If you see liquid between the stator and

stator ring, or from the needle port or a vent

tube, tighten the pressure adjusting screw as

explained in Section 8.0. If this fails to stop

the leak then replace the rotor seal and/or

stator face assembly.

10.2 NEEDLE SEAL LEAKAGE

Since the outside diameter of syringe

needles can vary, the needle seal (Teflon1

sleeve in the rotor seal) may not seal

correctly around a needle that is smaller than

average. This will result in the loss of

accuracy in loading the sample. To make a

good seal, remove the needle from the needle

port and push in on the plastic needle guide

with the eraser end of a pencil. Repeat if

necessary.

10.3 USE OF AQUEOUS BUFFERS OR

SALT SOLUTIONS

To prevent the formation of salt crystals in

the valve which can scratch the rotor seal,

flush out the flow passages and the needle

port with water after using salt solutions.

10.4 USE OF HIGH pH SOLUTIONS

The standard rotor seal in Models 8125 and

8126 is Vespel1, a polyimide with good wear

resistance. Vespel is sensitive to alkaline

attack when exposed to solutions having a

pH of 10 or more. Use a PEEK or Tefzel1

rotor seal for alkaline solutions.

10.5 ACCURACY OF SAMPLE LOOPS

Sample loop sizes are not actual values.

Actual volumes can differ by ± 10% for a 20

µL loop. Smaller loops show greater

differences. For actual injection volume, use

the partial-filling manual sample loading

method.

11.0 RECOMMENDED SPARE PARTS

Rheodyne offers a RheBuild™ Kit for

maintaining the quality performance of your

valve. The kit includes all the necessary

parts, tools, and instructions.

8125-999 RheBuild Kit for 8125 and 8126

12.0 WARRANTY

All Rheodyne products are warranted

against defects in materials and

workmanship for a period of one year

following the date of shipment by Rheodyne.

Rheodyne will repair or replace any

Rheodyne product that fails during the

warranty period due to a defect in materials

or workmanship at no charge to the

customer. The product must be returned to

Rheodyne’s factory in original packaging or

equivalent, transportation prepaid. Damage

occurring in transit is not covered by the

warranty. This limited warranty is

Rheodyne’s sole warranty of its products,

and all other warranties of merchantability or

fitness for any particular purpose are hereby

disclaimed. Under no circumstances will

Rheodyne be liable for any consequential or

incidental damages attributable to a claimed

failure of a Rheodyne product, even if

Rheodyne has been placed on notice of

possibility of such damages.

Fig. 13. Removing the stator ring with two hex

screws.

Set Screws (2)

Needle Guide

Handle Assembly

Shaft Assembly*

* Shaft Assembly includes Rotor, Shaft, and Pins.

Seal Pins (4)

Needle Port Tube

Rotor Seal

Stator Face Assembly

Drain Slots

Stator Ring

Stator Stator Screws

Isolation SealNotch

Fig. 12. Exploded view of Model 8126.

Page 4 of 4

2320667A

9/99

1Vespel, Tefzel, and Teflon are trademarks of E.I. DuPont.

Fig. 14. Alignment of punch marks.

Four Punch Marks

in Line

Correct Meshing of Gear

and Rack Teeth

Rheodyne LLC • A Unit of IDEX Corporation • 600 Park Court, Rohnert Park, CA 94928 • (707) 588-2000 • Fax (707) 588-2020

www.rheodyne.com