Please note: Drawings are not shown to scale

You will need the following:

Someone to assist you

Sturdy stepladder

10mm spanner

10mm nut driver

13mm spanner

Hacksaw-preferably small

Tape measure

Skeleton gun for silicone

Spirit level

Drill (drill bits HSS 4.5 & 7mm. Masonry 6mm)

plus a few common tools

Bags of readymix for the anchors if erecting

on a soil site

In addition there are a few tools which are

useful but not essential:

Glass sucker (for handling and adjusting the

large panes of glass) a rubber mallet and a

glazing paddle

These, more specialist tools, are available from

Greenhouses Direct if you wish to buy them.

Thoughts & considerations

Where you choose to site your greenhouse will

usually be dictated by the design of your garden

and personal choice so we will conne ourselves

to considering the different types of ground that

it is built on. Rhinos can be sited on either soil or a

hardstanding. Either way the main requirements

are that the greenhouse is erected both square

& level.

Soil bases are perfect provided that the soil is

compactedsothatitdoesn’tsubsideorgetwashed

away, avoid freshly dug soil for this reason. If

siting on a lawn we would recommend that the

turf is cleared from an area at least 300mm (1ft)

greater than the size of the greenhouse - you

won’t want grass inside and this will allow an

edge to mow over rather than cut right up to the

greenhouse base.

General Points

before you start

1st of 6 pages

Rhinos all include integral aluminium bases

which sit directly onto the soil and have sturdy

ground anchors which can be concreted in to

the ground at strategic points. The concreting is

done last of all once the greenhouse is glazed.

Hardstanding bases are no problem for the

Rhino as the integral base has a wide lip.

Brick plinth bases are perfect for the Rhino,

but please make sure you study the specic

base plan on page 4.

Please also consider the following points:

Is the site level?

If not nd some means of packing underneath

the aluminium base it must be level.

Is the area likely to ood?

Water on the outside of an oversize concrete pad

is likely to make its way under the aluminium

base and settle inside the greenhouse unless

steps are taken to seal the base or drain the

water away.

How will you x it down?

Please see the next page

Proximity to fences, buildings etc

If at all possible leave adequate room all round

the Rhino to ease initial construction and any

subsequent maintenance for the greenhouse

and adjacent walls or fences.

Construction order

It is important to construct the Rhino in the

correct order. You may expect to have to position

the integral base as the rst job but this would

in fact greatly complicate matters later on.

Once again it will help to have read the plans in

advance.

Open & identify the parts

We suggest that you are careful to lay out parts

in an orderly fashion - grouping sections that

are made of the same prole together but in

their different lengths.

Most sections either have a sticker containing

the part number on them or are grouped with

identical sections which include a sticker. This

will help you greatly in identifying the various

parts.

Consider the weather

Erecting a large greenhouse will take more than

a day. Before you start please consider what

steps you will take to protect the greenhouse

if you are leaving it overnight or for a few

days without the frame being fully glazed and

anchored. Even a completely unglazed frame

will need to be anchored down in some way if

there is a possibility of strong winds.

Colour powdercoat nish

The optional powdercoated nish is strong and

durable. Unlike traditional paint nishes it will

not ake and is very resistant to fade. Don’t be

concerned if you notice some areas on a few

proles where the paint is less dense. This is

due to some of the proles being very intricate

with channels & cavities on both sides. The

decision of where the primary and secondary

painting surfaces and jig points are situated is

deliberate. This takes into account how visible

the prole will be on the nished greenhouse.

Caution

The edges of the extrusion can be extremely

sharp. You may wish to consider wearing thin

gloves at certain stages.

During glazing and handling glass we advise

you to wear protective eye goggles.

Handling glass

While you are moving & handling the glass be

aware that the toughening process makes it

vulnerable to knocks on its edges. Catching an

edge on concrete or brickwork whilst carrying it

can easily cause it to break. Of course, when it

is installed in the greenhouse the edges are all

well protected.

Step ladders

Take care when working on your stepladder,

especially when the ground is soft.

Is your level, level?

Thismay sound a daftquestion butit issurprising

how often it crops up. You will have real difculty

erecting your greenhouse if your level is giving

the wrong readings.

Check it before you start:

Try it on a surface you believe to be level, note

the position of the bubble, turn it round (180

degrees) and check that the bubble gives the

same reading. If it doesn’t buy a new one quickly

–you’ve just saved yourself a lot of work!

Introduction

Plan ahead

See page 24 point 12. The roof vents are slid into

the end of the ridge section so enough clearance

must be allowed when siting the greenhouse.

Construction method

The greenhouse is assembled using aluminium

bolts & nuts because they will not rust. These

can be tightened reasonably tight but be careful

not to over-tighten, as being much softer than

steel they will eventually sheer.

PLEASE NOTE! BEFORE USING THESE

FIXINGS IT IS ESSENTIAL THEY ARE

LUBRICATED WITH WD40 OR EQUIVALENT.

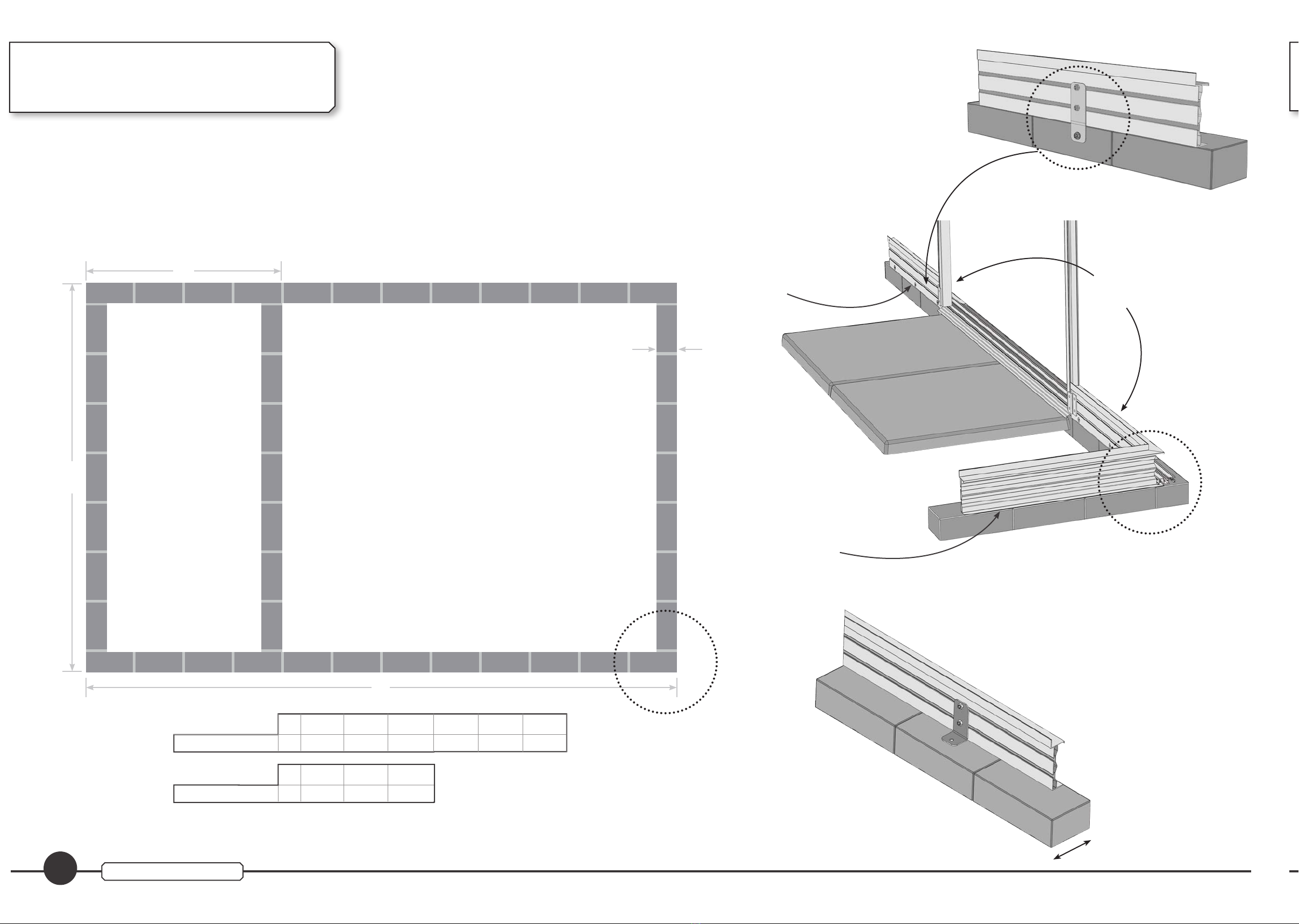

The method used mostly in the construction of

your greenhouse is shown below. The head of a

bolt is slid in to the channel in the glazing bar

where it is held captive and cannot turn.

Generally it is best to leave nuts reasonably loose

in the early stages of assembling the frame as it

is possible to tighten them in slightly the wrong

position and then nd that the various parts will

not t together correctly. Certainly where the

bolt is passing through two holes such as at the

eave and ridge plates it is best to leave them

loose. Where the bolt slides in a captive nut

channel such as when tting the glazing bars

you will have to partly tighten the nut so that

the bolt doesn’t slide out.

The instructions will tell you when to go round

and tighten the bolts.

1

Rhino Premium 10ft wide