Table of Contents

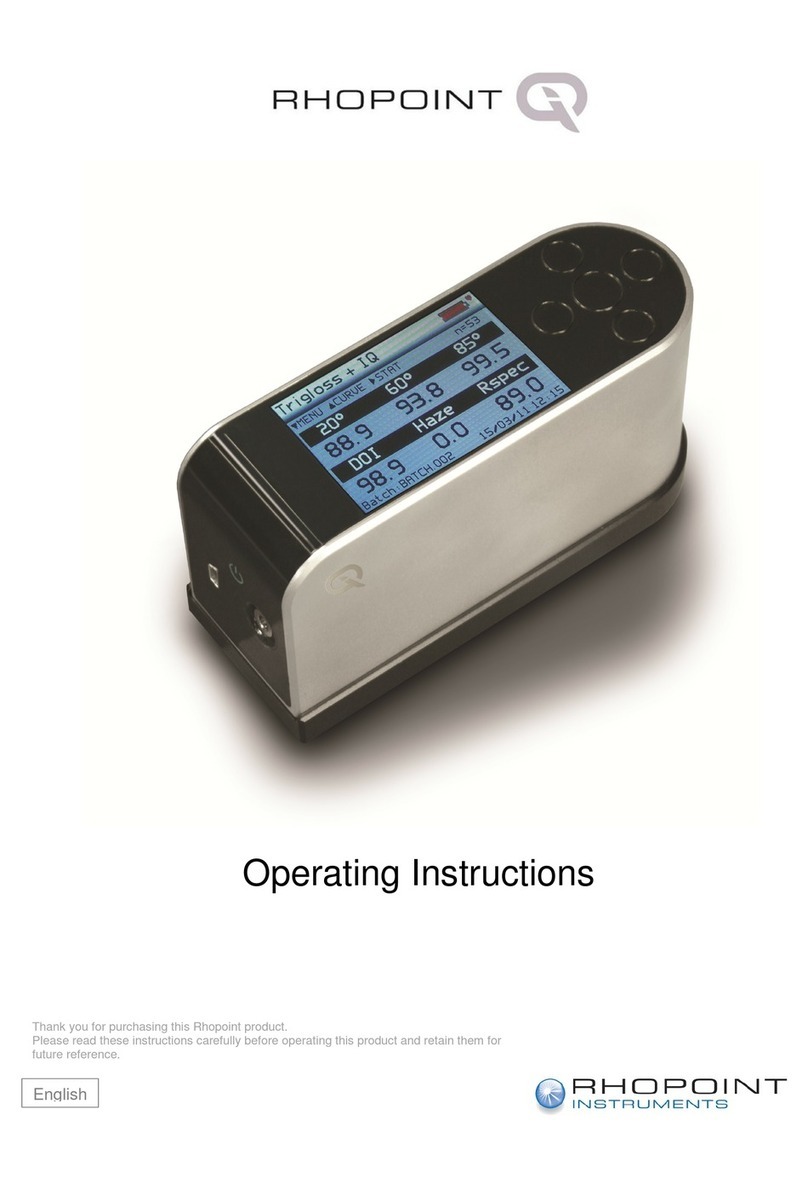

Novo-Gloss IQ -Specular Goniophotometer .......................... 1

Why is specular appearance important? .................................. 2

Disadvantages o standard gloss measurement....................... 3

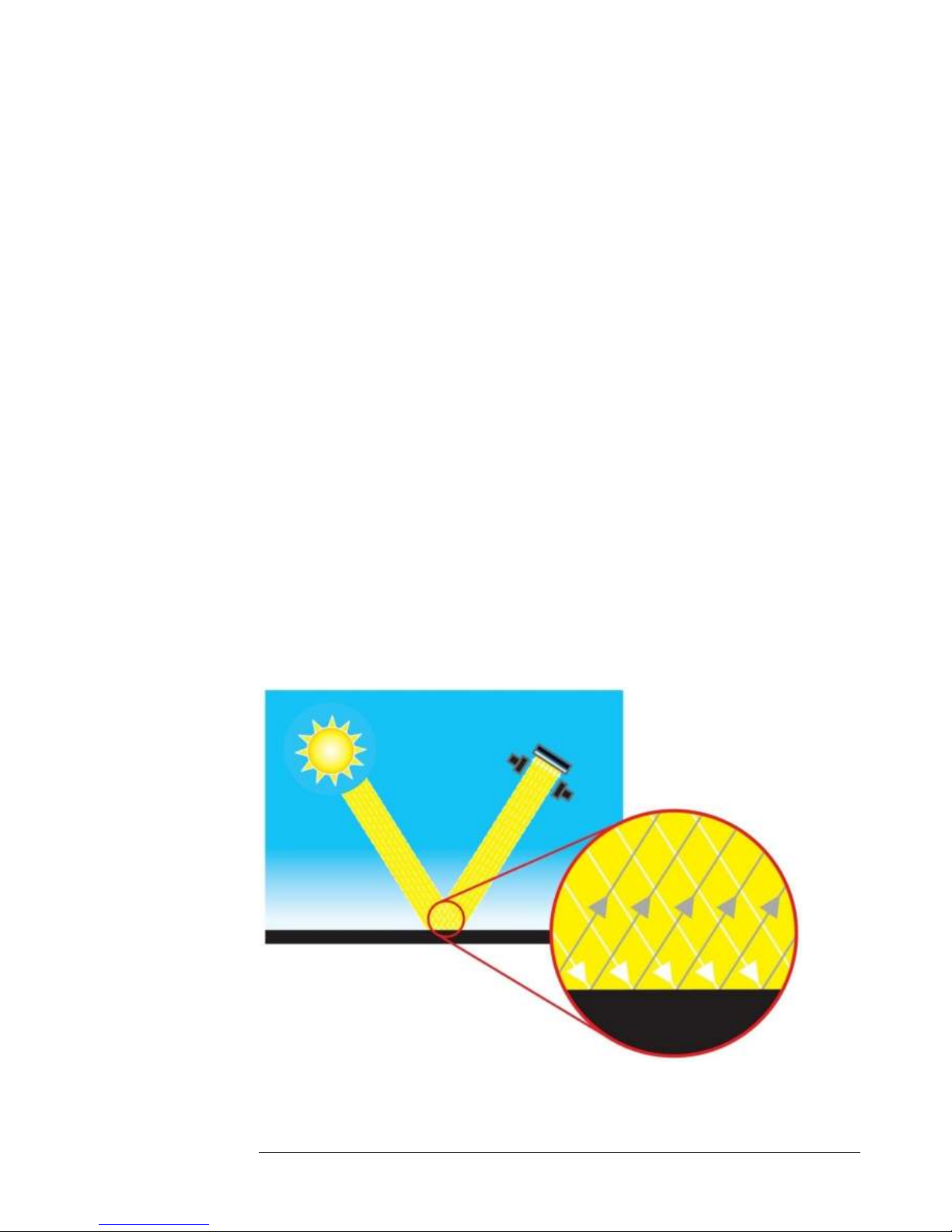

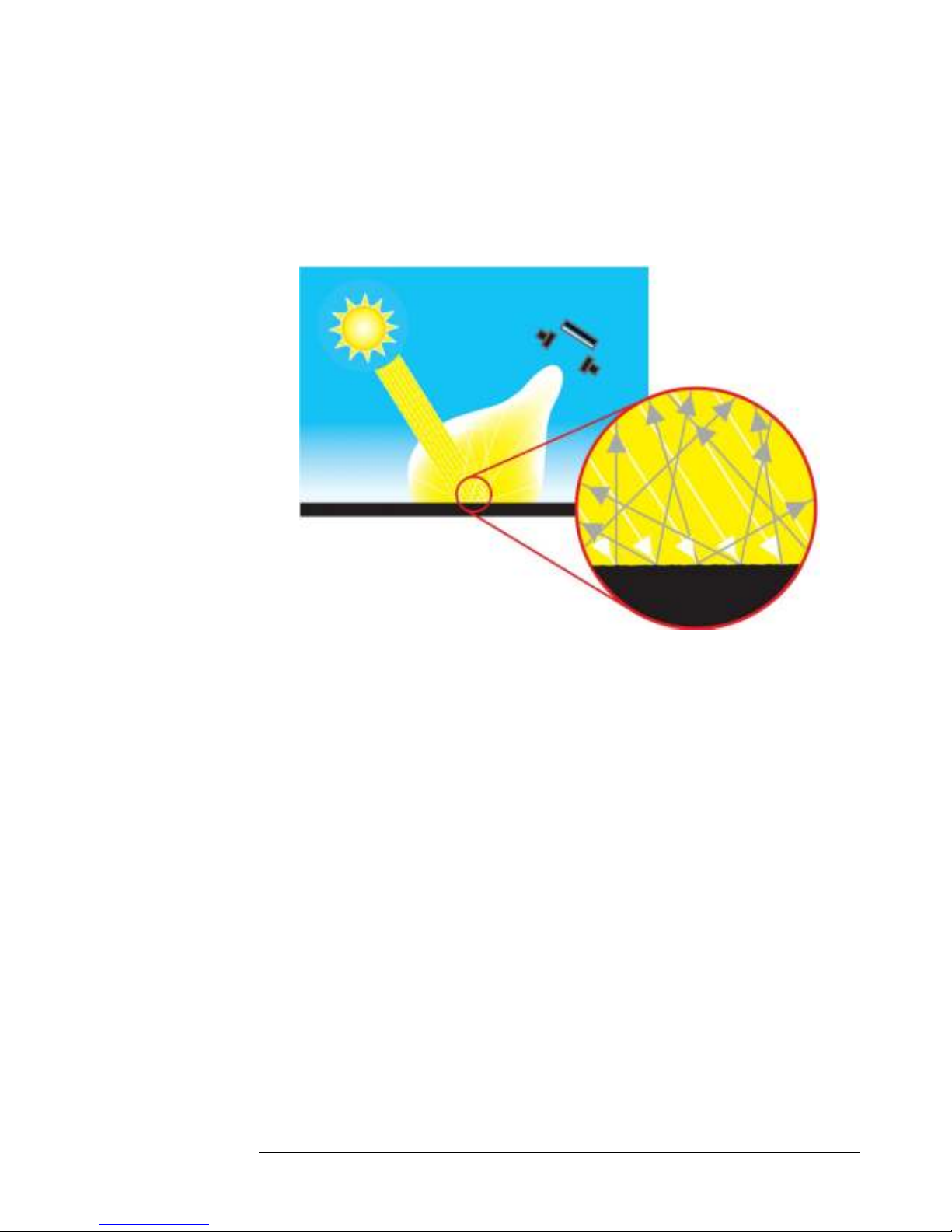

Specular re lection and sur ace texture .................................... 4

Measuring Standard Gloss with the Novo-Gloss IQ.................. 6

Haze ........................................................................................ 6

Distinctness o Image (DOI) ..................................................... 8

RSpec- Peak Specular Re lectance ......................................... 9

Goniophotometric Pro ile........................................................ 10

Accessories............................................................................ 12

Power..................................................................................... 13

Control Panel ......................................................................... 14

Navigating the Menus............................................................. 15

Accessing the Main Menu ...................................................... 15

Using Short Cuts .................................................................... 16

Measurement Screen............................................................. 17

Statistics and Memory............................................................ 17

Calibration.............................................................................. 18

Taking a measurement........................................................... 21

Instrument set up options ....................................................... 22

Set up menu 1........................................................................ 22

Adjusting the stored calibration values ................................... 22

Switching the Memory on/o .................................................. 22

Set up menu 2........................................................................ 23

Switch the Goniophotometric curve on/o .............................. 23

Switch the Log Haze scale on/o ........................................... 23

Data Menu ............................................................................. 24

Delete the last reading rom statistics memory ....................... 24

Delete the all readings rom statistics memory ....................... 24

Output the saved memory to PC ............................................ 24

Index ...................................................................................... 25

www.64817.com TEL:0756-2236929