RP-II-CS8G [C]

18

Sheet 3 of 16

www.richards-mfg.com

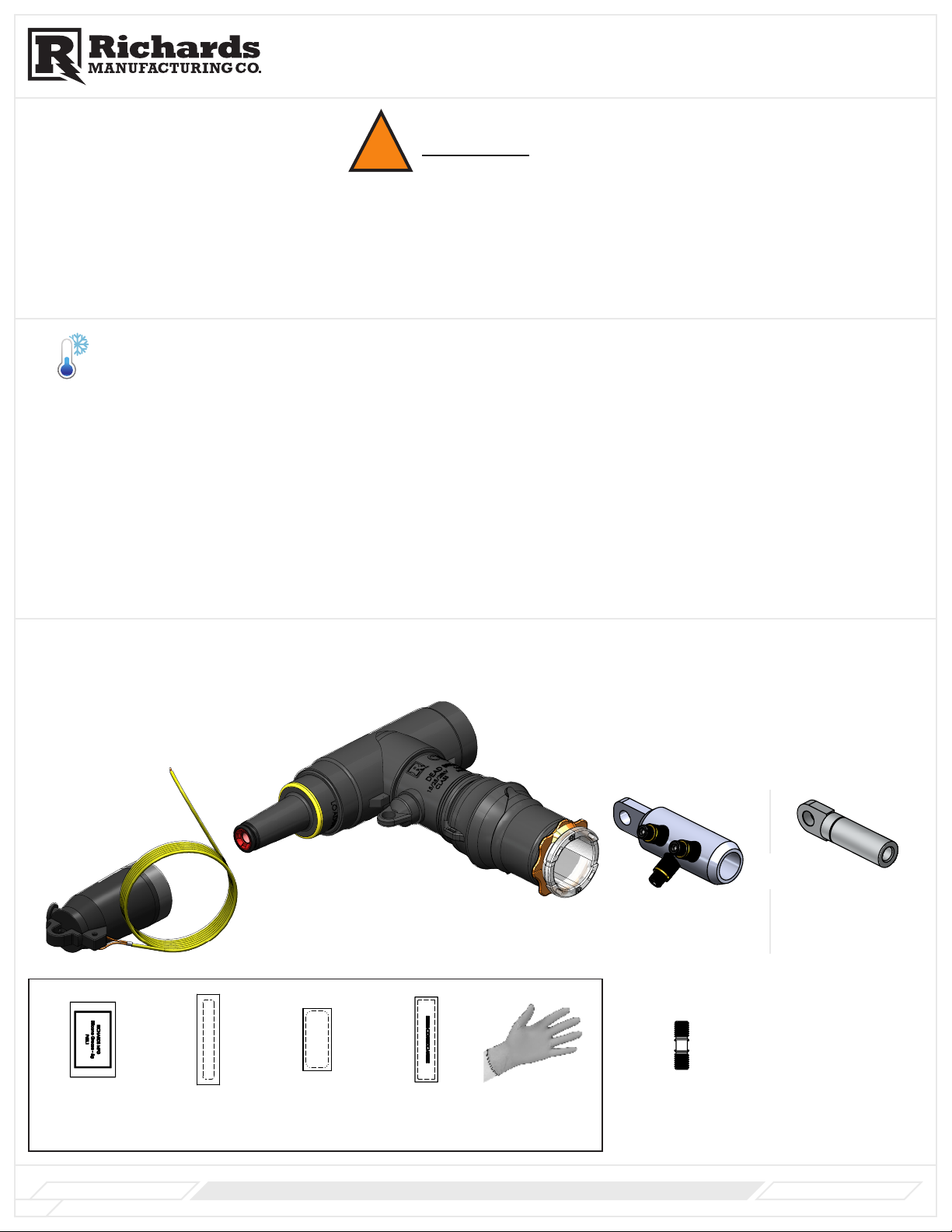

Product Family

CS8

TIP: Use To-Scale Cable Cutback Template as aid to prepare cable.

NOTE: Certain items used, such as PVC tape, may not be included.

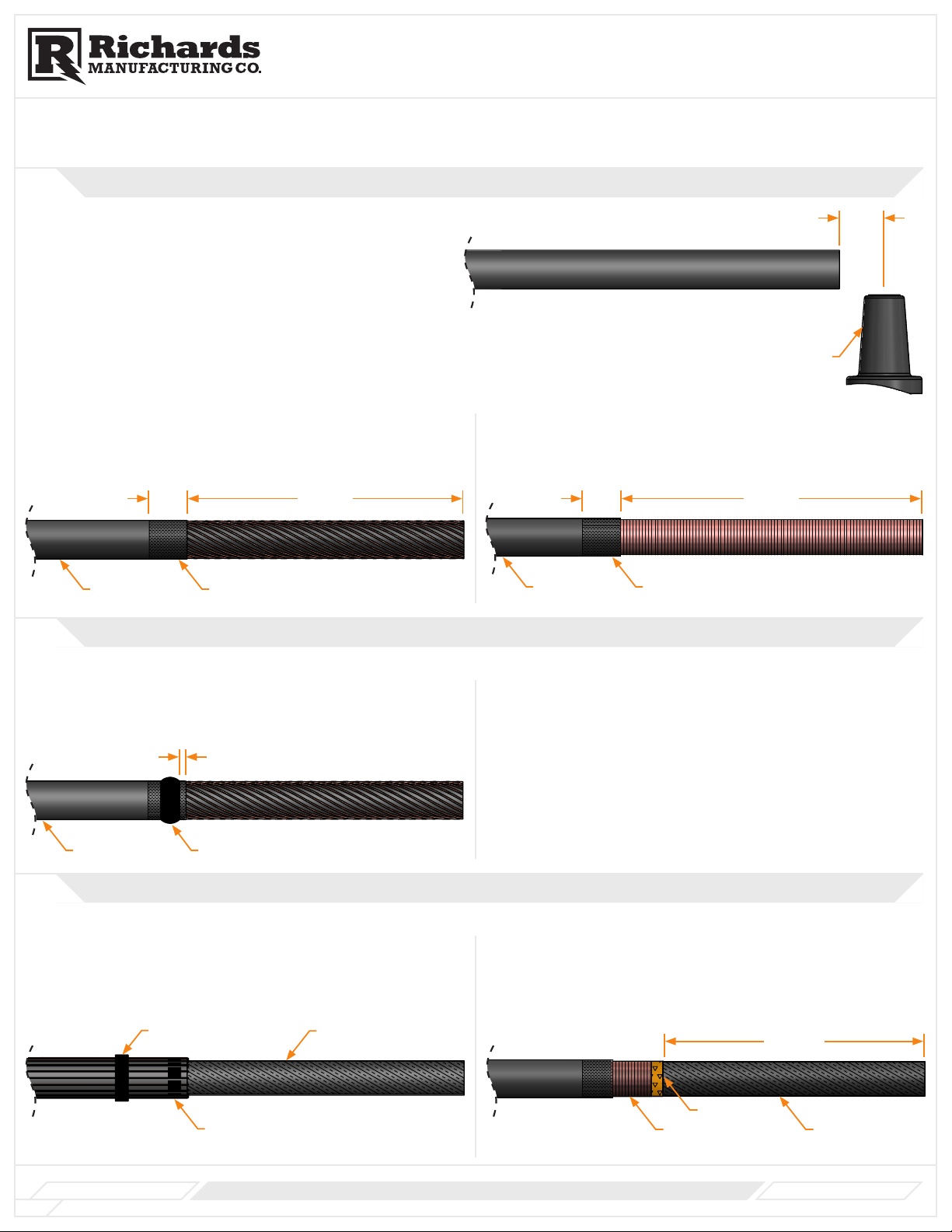

1Positioning Cable & Exposing Metallic Shield

A. Straighten and train cable end. Cable should be free to move

approximately 2" in either direction.

B. Cut cable to dimensions shown.

C. Clean cable jacket approximately 24" from end of cable.

TIP:

Use to-scale cable cutback template on last page as aid to prepare cable.

NOTE:

Certain items used such as mastic, PVC tape, shrink tube, etc. may not be included.

Product Family

LCN/LCT

Installation Instructions

www.richards-mfg.com

RP-II-62LCN [E]

Rev. E

Sheet 9 of 9

517 Lyons Ave.

Irvington, NJ 07111

Phone (973) 371-1771

Fax (973) 371-4304

www.richards-mfg.com

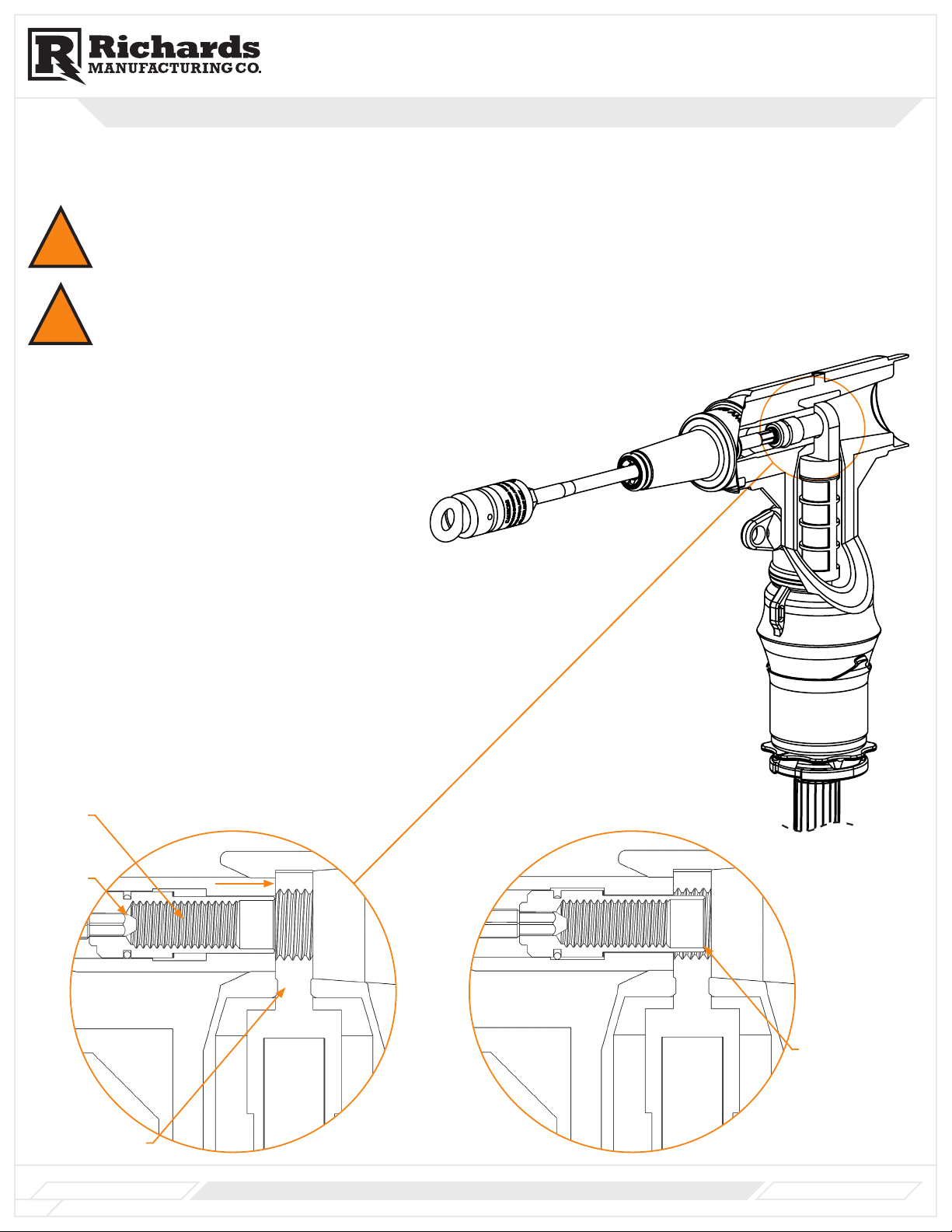

1 3/4”

Bushing or

Mating Part

For Strap/Wire Shielded Cable

D. Remove cable jacket to dimensions shown.

E. Abrade area as shown.

For Metallic Tape/LC Shielded Cable

D. Remove cable jacket to dimensions shown.

E. Abrade area as shown.

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

Cable Jacket Abraded Area

1 1/2” REF. 11”

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

1 1/2” REF. 12”

Cable Jacket Abraded Area

A. Straighten and train cable end. Cable should be free to move

approximately 2" in either direction.

B. Cut cable to dimensions shown.

C. Clean cable jacket approximately 24" from end of cable.

TIP:

Use to-scale cable cutback template on last page as aid to prepare cable.

NOTE:

Certain items used such as mastic, PVC tape, shrink tube, etc. may not be included.

Product Family

LCN/LCT

Installation Instructions

www.richards-mfg.com

RP-II-62LCN [E]

Rev. E

Sheet 9 of 9

517 Lyons Ave.

Irvington, NJ 07111

Phone (973) 371-1771

Fax (973) 371-4304

www.richards-mfg.com

1 3/4”

Bushing or

Mating Part

For Strap/Wire Shielded Cable

D. Remove cable jacket to dimensions shown.

E. Abrade area as shown.

For Metallic Tape/LC Shielded Cable

D. Remove cable jacket to dimensions shown.

E. Abrade area as shown.

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

Cable Jacket Abraded Area

1 1/2” REF. 11”

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

1 1/2” REF. 12”

Cable Jacket Abraded Area

A. Straighten and train cable end. Cable should be free to move

approximately 2" in either direction.

B. Cut cable to dimensions shown.

C. Clean cable jacket approximately 24" from end of cable.

TIP:

Use to-scale cable cutback template on last page as aid to prepare cable.

NOTE:

Certain items used such as mastic, PVC tape, shrink tube, etc. may not be included.

Product Family

LCN/LCT

Installation Instructions

www.richards-mfg.com

RP-II-62LCN [E]

Rev. E

Sheet 9 of 9

517 Lyons Ave.

Irvington, NJ 07111

Phone (973) 371-1771

Fax (973) 371-4304

www.richards-mfg.com

1 3/4”

Bushing or

Mating Part

For Strap/Wire Shielded Cable

D. Remove cable jacket to dimensions shown.

E. Abrade area as shown.

For Metallic Tape/LC Shielded Cable

D. Remove cable jacket to dimensions shown.

E. Abrade area as shown.

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

Cable Jacket Abraded Area

1 1/2” REF. 11”

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

1 1/2” REF. 12”

Cable Jacket Abraded Area

11” 11 3/4”

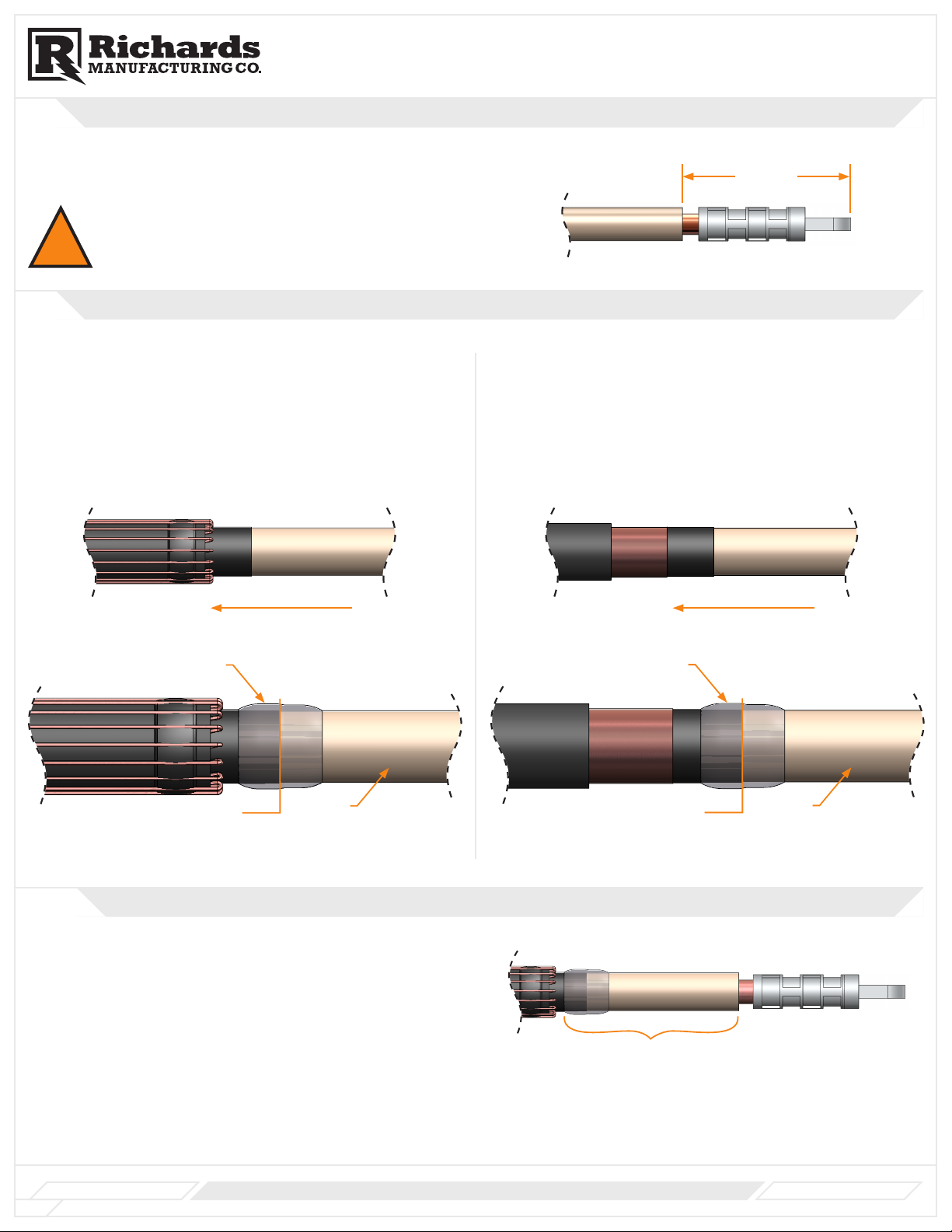

2Applying Jacket Mastic

For Strap/Wire Shielded Cable

A. Apply one piece of jacket mastic at position shown by stretching and

wrapping with light tension fully around outer jacket.

For Metallic Tape/LC Shielded Cable

Go to Step 3

NOTE: Jacket mastic will be applied in Step 10.2

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

Cable Jacket Jacket Mastic

1/4”

3Exposing Cable Semi-Conductive Shield

For Strap/Wire Shielded Cable

A. Fold back strap/wire shields and press firmly into jacket mastic.

B. Secure strap/wire shields 3” back from jacket mastic with binding wire

or zip tie as shown.

For Metallic Tape/LC Shielded Cable

A. Wrap 2 layers of PVC tape at dimension shown to secure metallic shield.

B. Remove metallic shield up to PVC tape as shown.

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

Binding Wire or Zip Tie Semi-Conductive Shield

Jacket mastic under strap/wire shield

For Strap/Wire Shielded Cables

For Strap/Wire Shielded Cables

STEP 0-Positioning

the Cable

STEP 1-Exposing

Cable Shielding

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

For Metallic Tape Shielded/LC Shielded

STEP 3- Exposing Cable

Semi-Conductive Shield

For Strap/Wire Shielded Cables

TIP:

NOTE:

Jacket Mastic

STEP 2-Applying Jacket

Mastic

Jacket Mastic

Product Family

CSHN/CSHT

Installation Instructions

10”

PVC Tape

Semi-Conductive

Shield

Metallic Shield

10”