Series SCK, double mechanical seal to DIN EN 12756 Page 2

9220-013-en Revision 11

TM 7827 Edition 03/2019

List of Contents

List of Contents.........................................2

Relevant documents .................................2

1Technical data ......................................2

2Safety, transport, storage and disposal

.....................................................3

2.1 Intended use ................................................ 3

3Product description .............................3

4Commissioning / Shutdown ................3

4.1 Initial commissioning ...................................3

4.2 Mechanical seals .........................................3

4.2.1 Use in an explosive area................................. 3

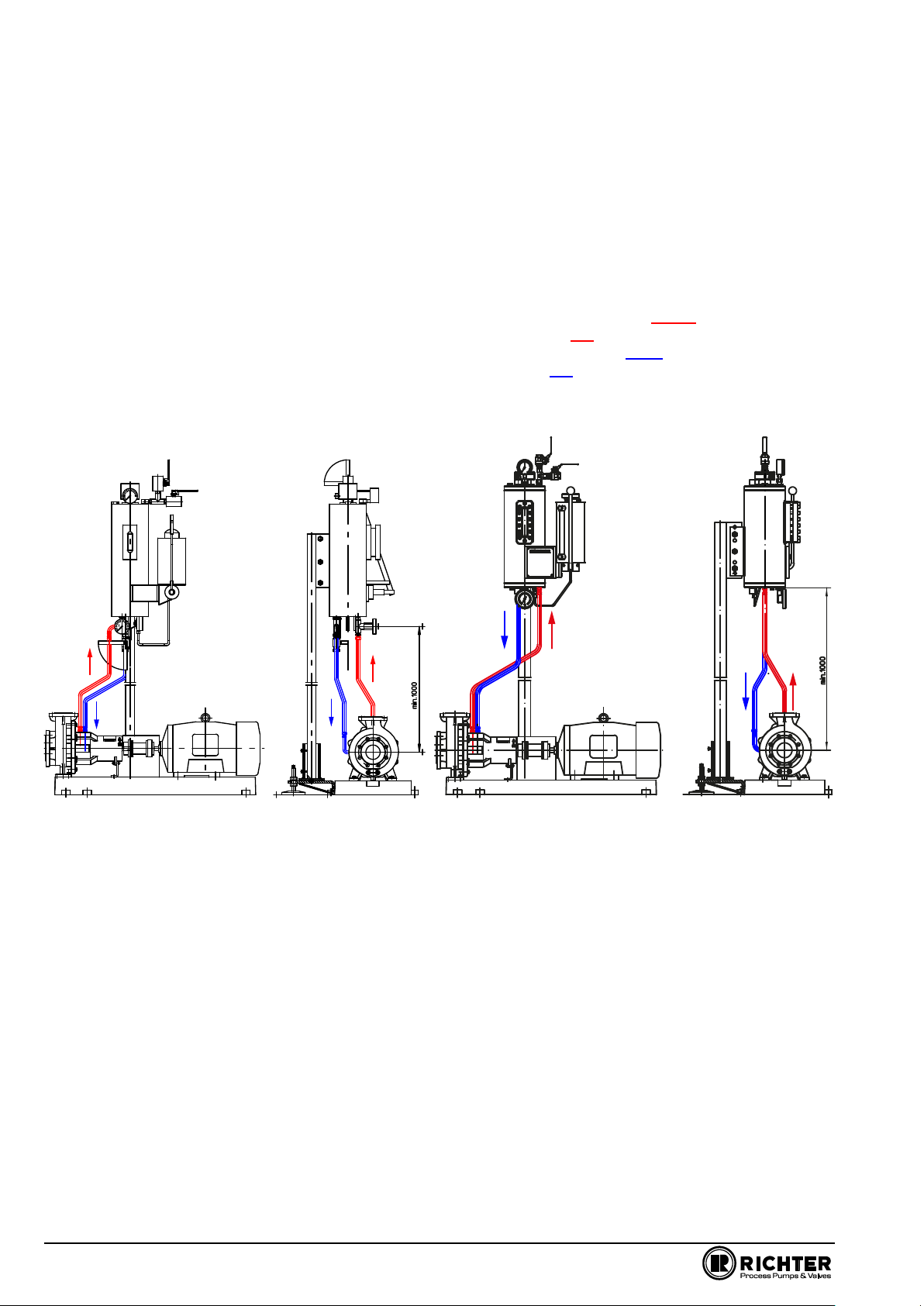

4.2.2 Double mechanical seal to DIN EN 12756....... 3

4.3 Improper operations and their consequences

(examples) ...................................................4

5Maintenance .........................................4

5.1 Dismantling of double mechanical seal to

DIN EN 12756 ............................................. 4

5.1.1 Dismantling of impeller and back plate............ 4

5.1.2 Dismantling the shaft sleeve ........................... 5

5.3 Notes on assembly ..................................... 5

6Malfunctions.........................................7

7Sectional drawing ................................7

7.1 Legend ........................................................ 7

7.2 Double mechanical seal to DIN EN 12756 8

Relevant documents

●Installation and operating manual SCK long life

grease and oil bath lubrication 9220-050-en

●Operating manual mechanical seal of the manufac-

turer

1 Technical data

Manufacturer :

Richter Chemie-Technik GmbH

Otto-Schott-Str. 2

D-47906 Kempen

Telephone: +49 (0) 2152 146-0

Fax: +49 (0) 2152 146-190

Internet: http://www.richter-ct.com

Authorised person acc. to machinery directive

2006/42/EG: Gregor Kleining

Designation :

Series SCK, mechanical seal:

●double, to DIN EN 12756

Materials :

Seal housing: Stainless steel

Wetted parts:

Mechanical seal: SSiC, carbon, Al2O3, PTFE, FKM,

FFKM etc., see also data sheet

Temperature range : see installation and

operating manual SCK, Section 1.

Temperature classes : see installation and

operating manual SCK, Section 2.6.7.