Series SGS/F Page 2

9540-005-en Revision 13

TM 9549 Edition 11/2018

List of Contents

List of Contents ................................................ 2

Relevant documents ........................................ 2

1Technical data............................................. 2

1.1 Type plate, CE and body markings..............3

1.2 Tightening torques...........................................3

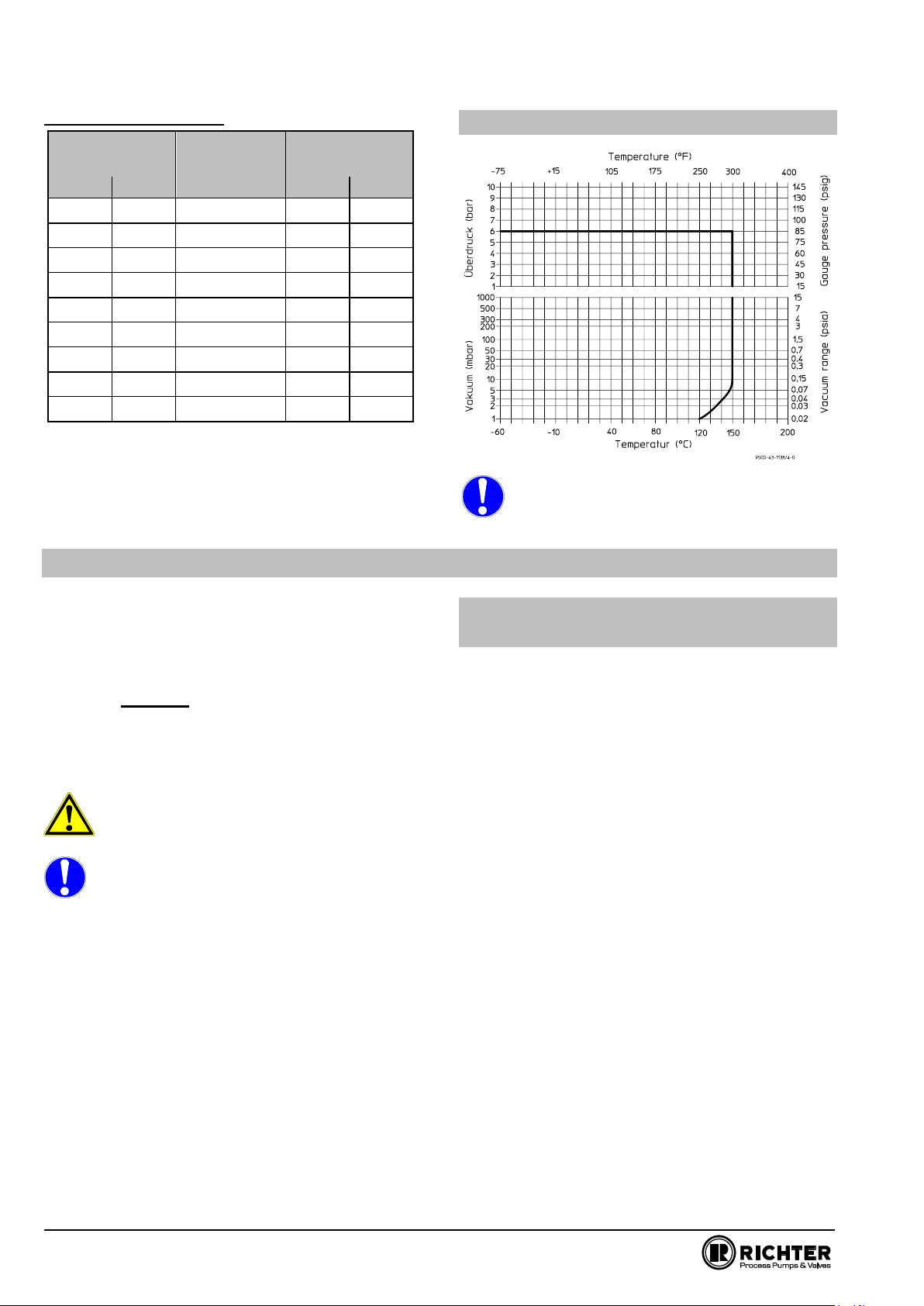

1.3 Pressure-temperature diagram .....................4

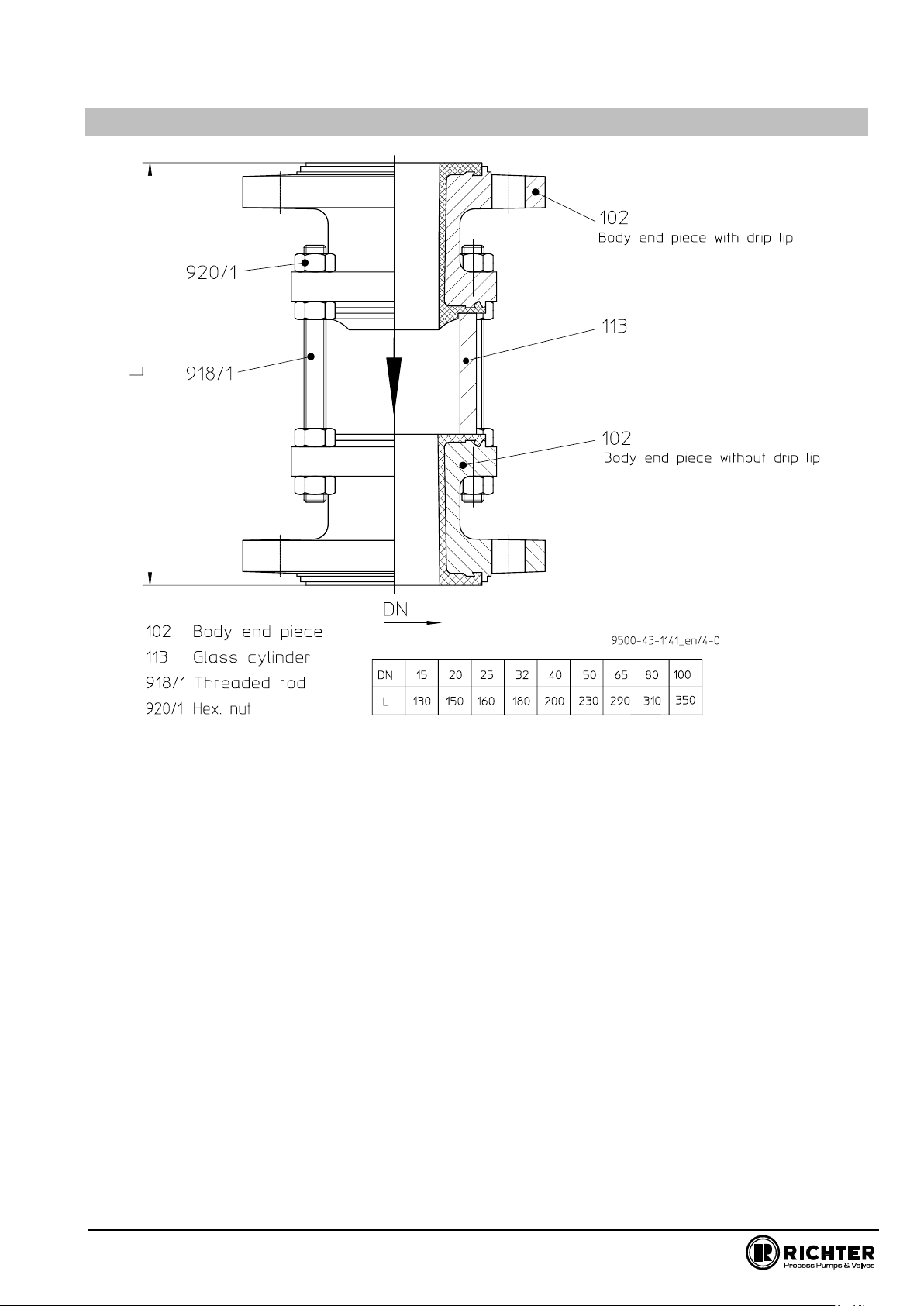

2Notes on safety ........................................... 4

2.1 Intended use ...................................................4

2.2 For the customer / operator ...........................5

2.3 Improper operation ..........................................5

3Safety notes for applications in potentially

explosive areas based on the Directive

2014/34/ EC (ATEX)..................................... 5

3.1 Intended use.....................................................5

4Safety note for valves, certified to Clean

Air Act (TA-Luft).......................................... 6

5Transport and storage ............................... 6

5.1 Storage.............................................................. 6

5.2 Return consignments ...................................... 6

5.3 Disposal ............................................................7

6Installation ................................................... 7

6.1 Flange caps and gaskets................................7

6.2 Direction of flow and installation position .....7

6.3 Grounding .........................................................7

6.4 Test pressure ...................................................7

7Operation ..................................................... 7

7.1 Initial commissioning .......................................7

7.2 Improper operation and their consequences7

7.3 Shutdown ..........................................................8

8Malfunctions ................................................ 8

9Maintenance ................................................ 8

9.1 Dismantling the cylindrical sight glass.........8

10 Sectional drawing ....................................... 9

Relevant documents

♦EG-Declaration of conformity

♦Declaration of conformity FDA & 97/48/EG

♦Manufacturer Declaration ATEX Directive

2014/34/EU

♦Manufacturer Declaration TA-Luft

♦Form for Safety Information Concerning the

Contamination QM 0912-16-2001_en

1 Technical data

Manufacturer:

Richter Chemie-Technik GmbH

Otto-Schott-Str. 2

D-47906 Kempen

Telephone: +49 (0) 2152 146-0

Fax: +49 (0) 2152 146-190

E-Mail: richter-info@richter-ct.com

Internet: http://www.richter-ct.com

Designation :

2-way Cylindrical Sight Glass, series SGS/F

Certified to Clean Air Act (TA Luft)

Strength and tightness (P10, P11) of the pressure-

bearing body tested to DIN EN 12266-1.

Flange connecting dimensions:

DIN EN 1092-2, type B

(ISO 7005-2 type B) PN 16

or flanges drilled to ANSI B16.5 Class 150

Face to face: DIN EN 558-1, basic series 1

(ISO 5752 basic series 1)

optionally face to face acc. to specifications

Materials :

Body material: Ductile cast iron EN-JS 1049 /

Lining material: PFA

on request non-conductive design

Glass cylinder: borosilicate glass

Temperature range : -60 °C to +150 °C

See pressure-temperature diagram in Section 1.3.

Operating pressure : from vacuum to max. 6 bar

See pressure-temperature diagram in Section 1.3.

Valve size :

DN 15, 20, 25, 32, 40, 50, 65, 80, 100