Ricoh G147 User manual

Other Ricoh All In One Printer manuals

Ricoh

Ricoh IM 550 Series User manual

Ricoh

Ricoh Pro C7100s User manual

Ricoh

Ricoh P C600 User manual

Ricoh

Ricoh LF 125 (H915) User manual

Ricoh

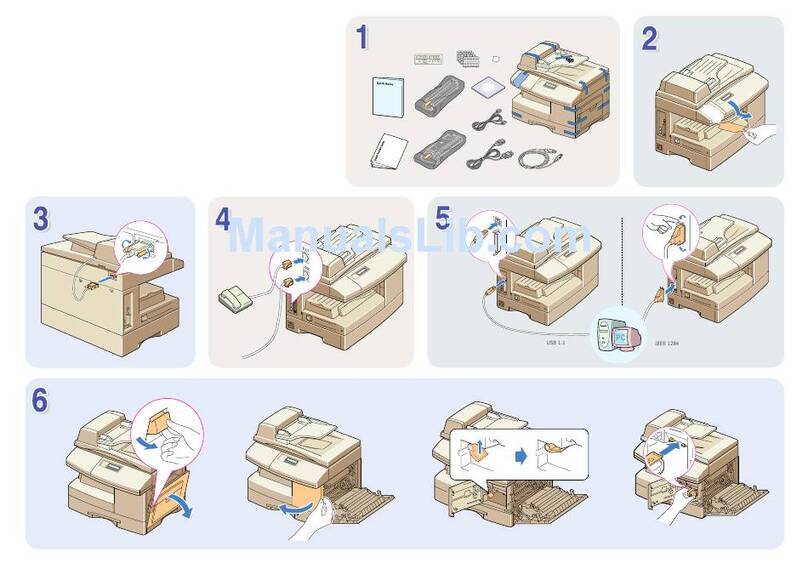

Ricoh Aficio MP 2000L Installation and maintenance instructions

Ricoh

Ricoh SP C260SFNw User manual

Ricoh

Ricoh AC204 User manual

Ricoh

Ricoh C3828 User manual

Ricoh

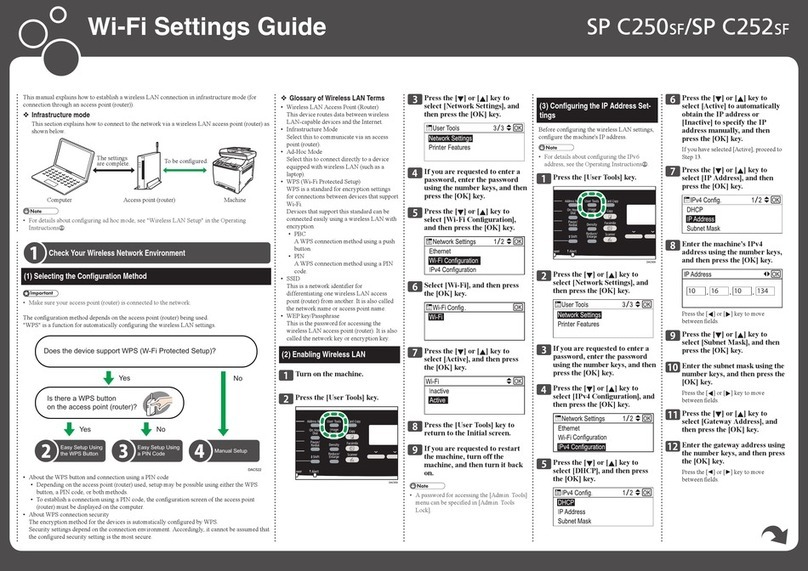

Ricoh SP C250SF Service manual

Ricoh

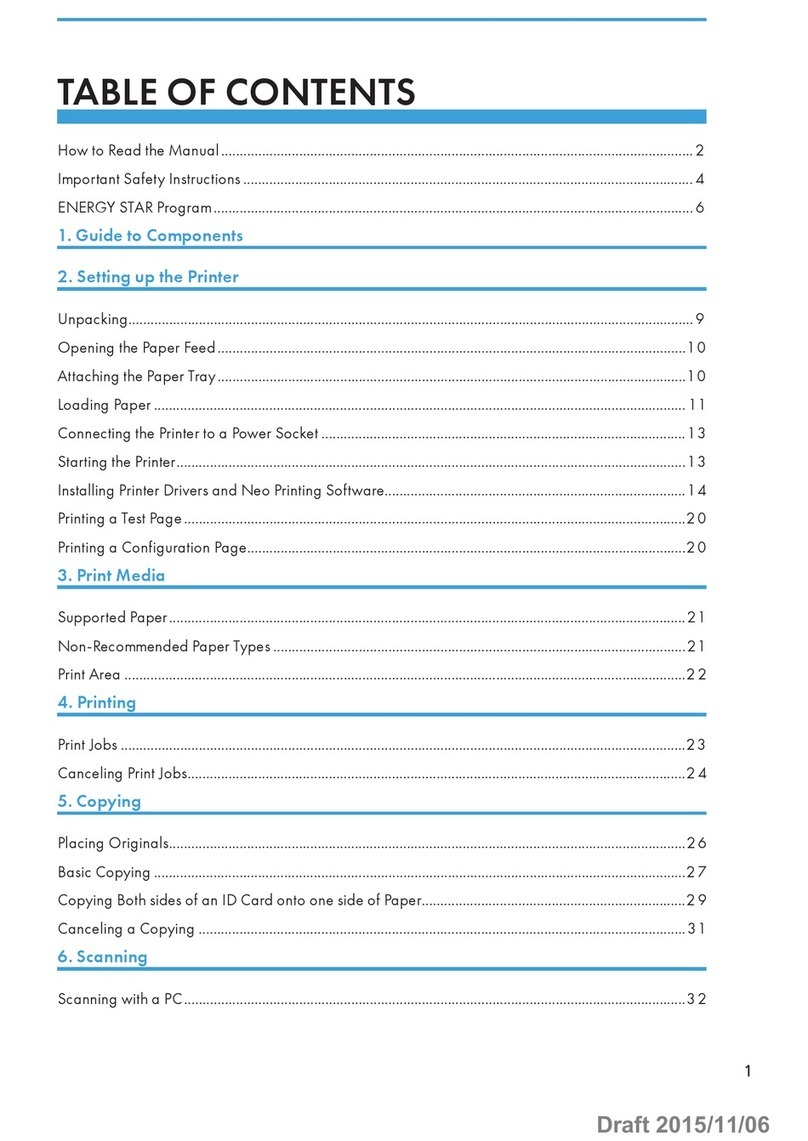

Ricoh MFSP150SUW1 User manual

Ricoh

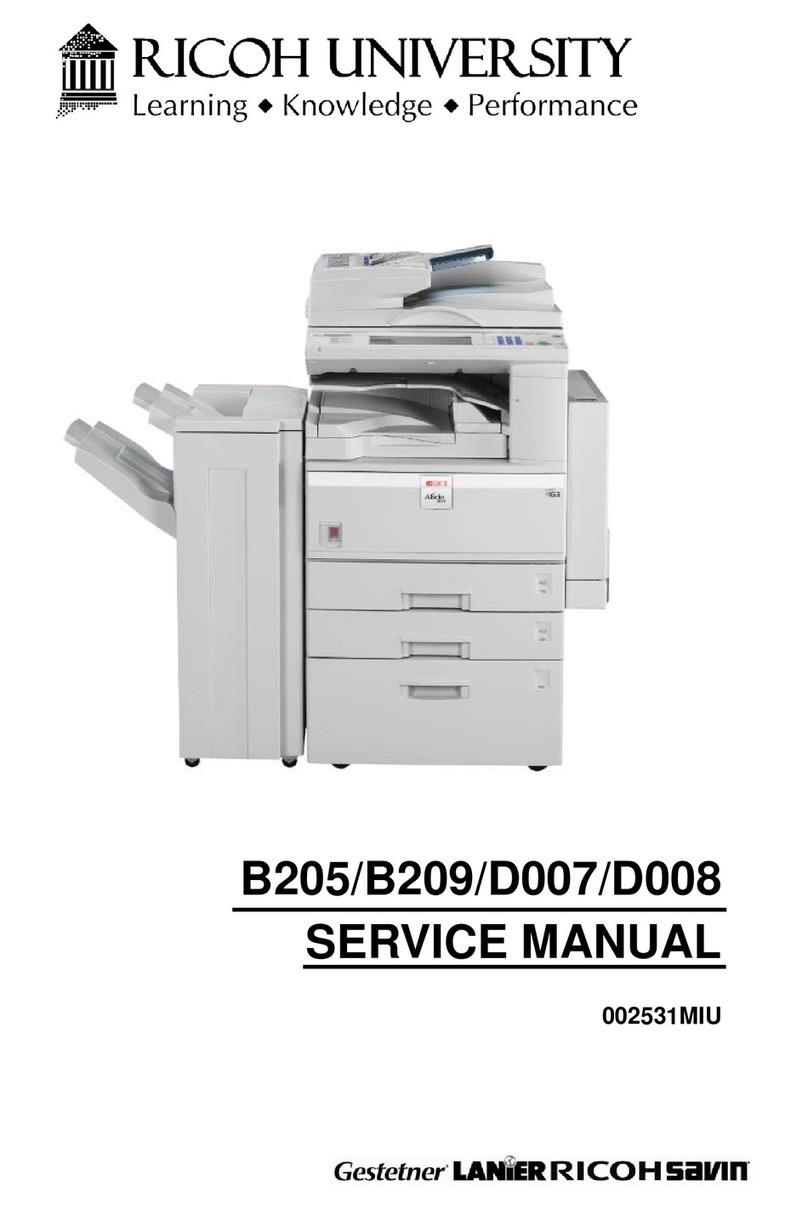

Ricoh B205 User manual

Ricoh

Ricoh D143 Quick start guide

Ricoh

Ricoh IM C6000 Series User manual

Ricoh

Ricoh Aficio 1515MF Manual

Ricoh

Ricoh Aficio 470W User manual

Ricoh

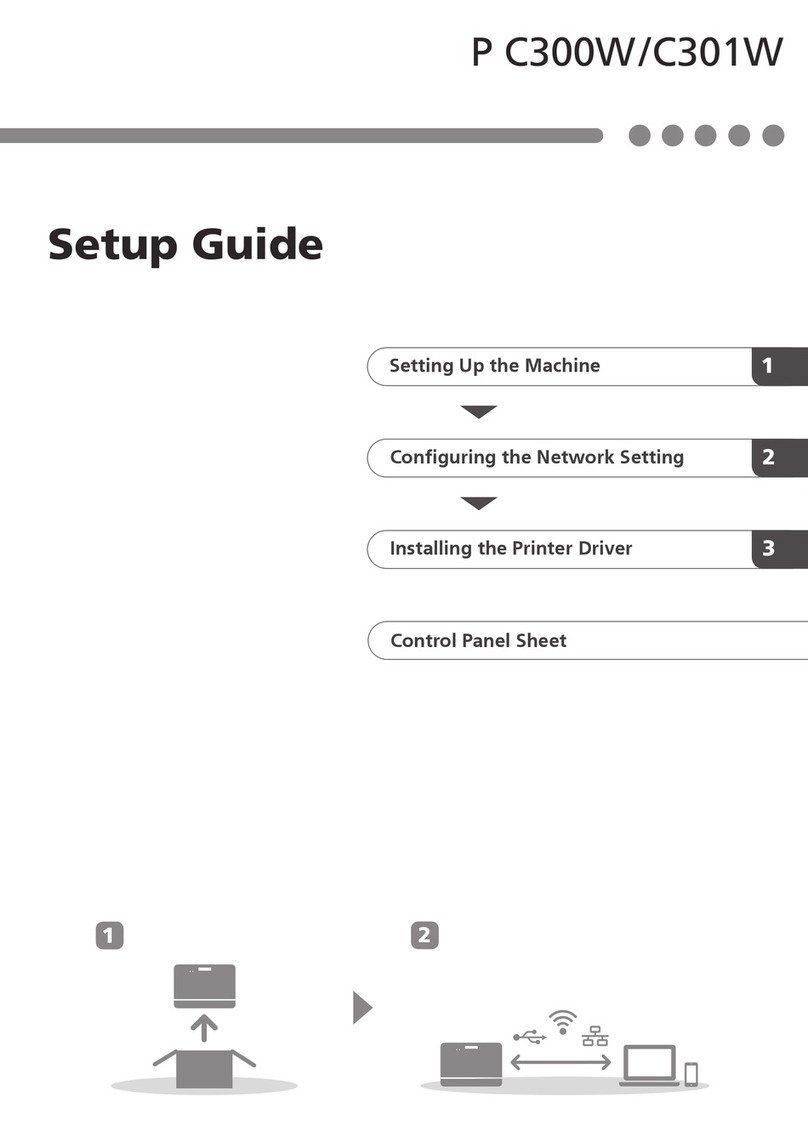

Ricoh P C300W User manual

Ricoh

Ricoh SP 3300 Series User manual

Ricoh

Ricoh Aficio 1027 Service manual

Ricoh

Ricoh Aficio SP 5210SF User manual

Ricoh

Ricoh M000 User manual