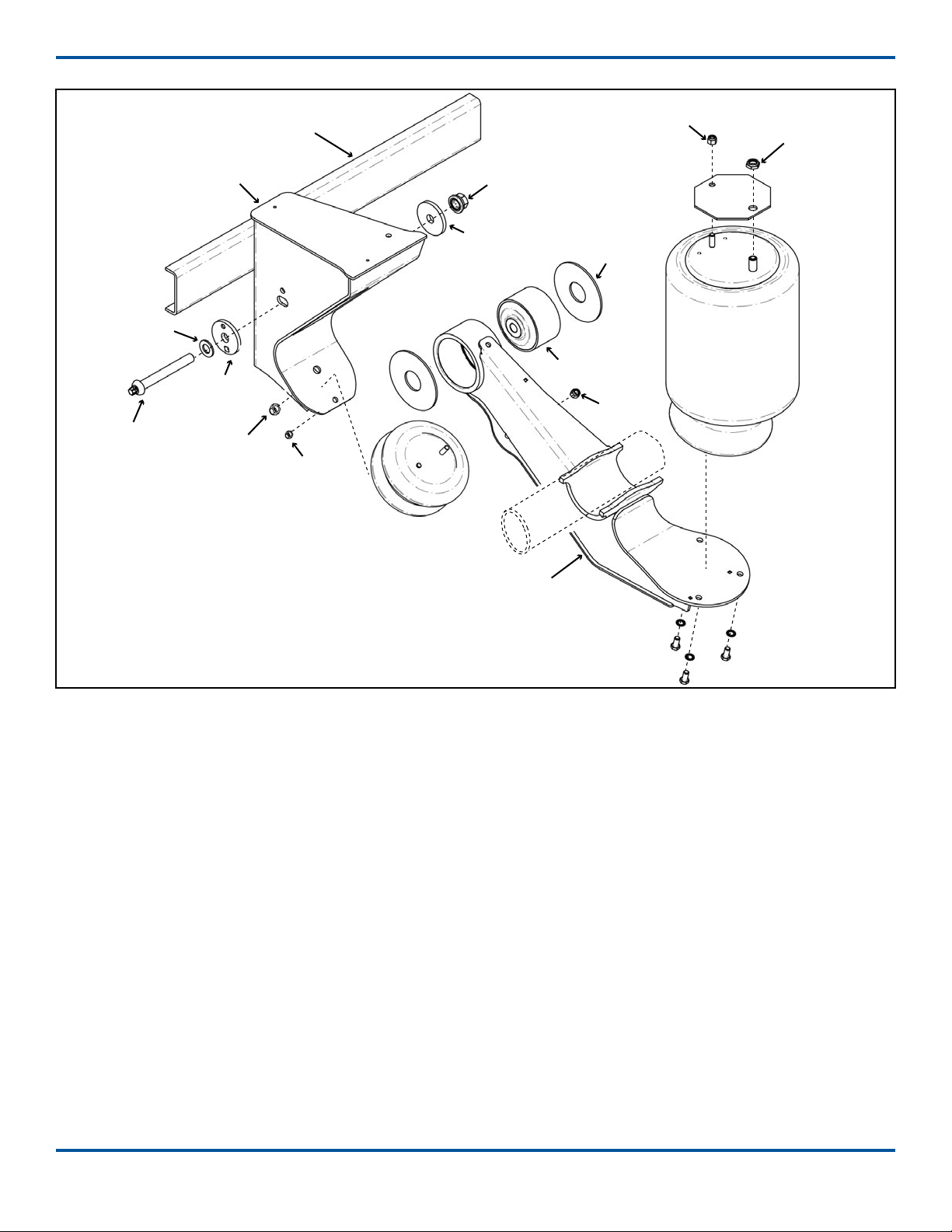

Back to TOC Page 6 215T-Trailer-ISM-RevF-03-24-21

Suspension Mounting

Refer to the engineering drawing for the range of ride

heights available and clearance requirements .

The suspension installer has the nal responsibility

of aaching the suspension to the vehicle frame.

Weld-On Installation Procedure

Recommended locations of customer-furnished ller

plates and supporting crossmembers for the hang-

ers and air spring mounting plates are shown on the

engineering drawing.

Welding method must use a minimum weld

tensile strength of 70,000 psi, per AWS specications.

1. Mark desired location of the hangers and ller

plates on the frame. Hangers must be installed

parallel to each other for proper axle alignment.

2. Mark the desired location of the air spring

mounting plates and ller plates on the frame.

NOTE: Protect other chassis components from

weld spaer during installation, if necessary.

3. Install ller plates for the hangers and air spring

mounting plates on the frame. Weld ller plates

to crossmembers with ¼” llet welds down the

length of the crossmember.

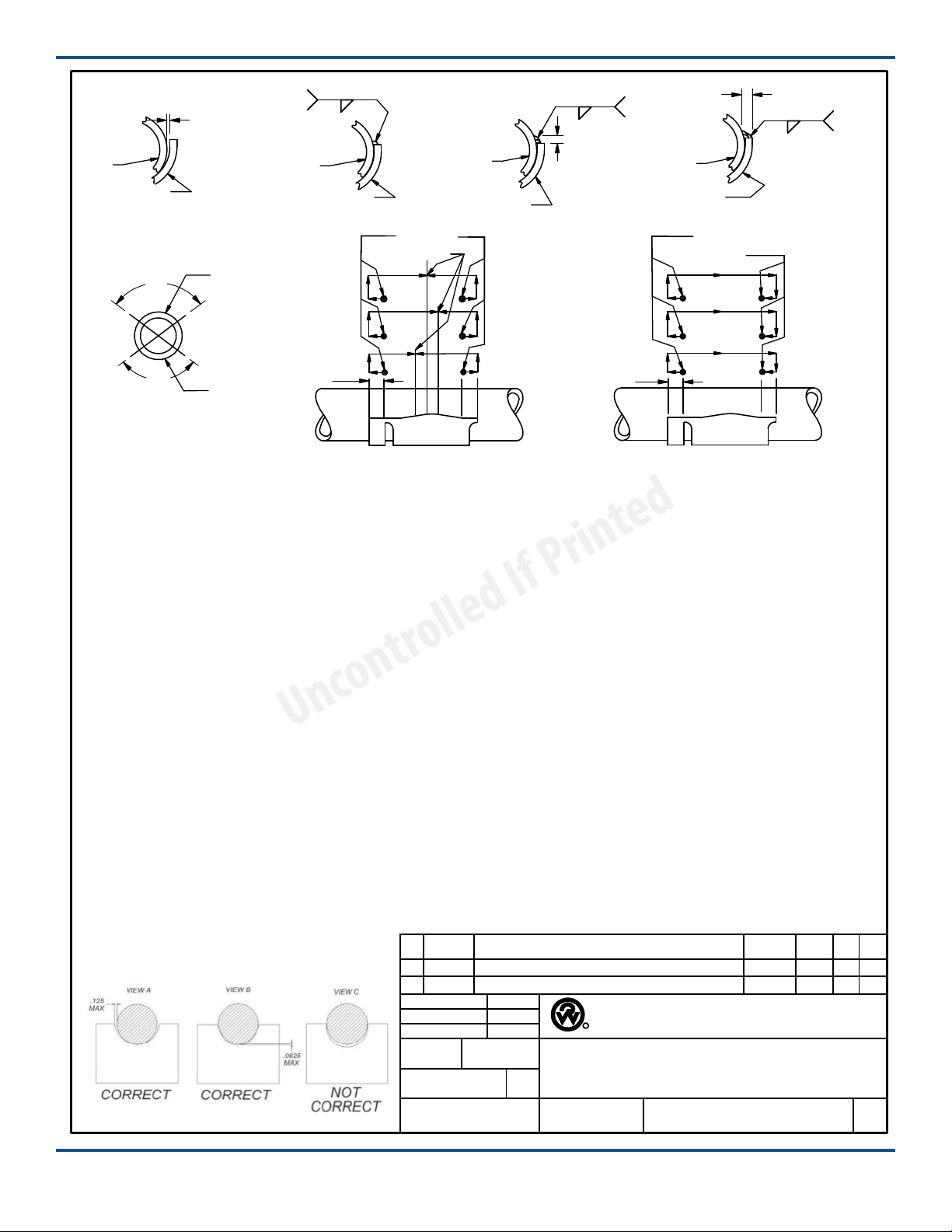

4. Weld the hangers to the frame/ller plates with

1/4” llet welds completely around the hangers.

Stop the welds 1/2” from the corners and edges.

5. Weld the air spring mounting plates to the frame/

ller plates with 3/16” llet welds.

6. Aach a crossmember or diagonal brace to the

front of the hangers with 1/4” llet welds.

Bolt-On Installation

Before installation, check to make sure that wires,

hoses or other components will not be aected by

drilling into the frame rail.

• Bolts/nuts for aaching the suspension to the

vehicle are supplied by the installer. Grade 8 bolts

and anged locknuts or locknuts with hardened

washers are recommended.

• Bolt holes are not provided in the air spring

mounting plates. Clamp mounting plates and

ller plates, if used, in place and drill (minimum)

two bolt holes in each mounting plate for installa-

tion onto the chassis.

Final Assembly and Inspection

1. Verify welds of frame hangers and air spring

mounting plates.

2. Inspect for loose/missing fasteners on the sus-

pension assembly. Verify suspension component

bolts/nuts are torqued to proper values (Pg 12).

3. Install wheels and tires.

When lowering an auxiliary axle on

an unloaded vehicle, pressure to the load air

springs must be reduced to below 10 psi. Failure

to reduce the air pressure could cause the ve-

hicle’s drive axles to rise from the ground and the

vehicle could roll in an unsafe manner.

4. Check that tires are inated to recommended

pressure. Check wheel hubs for proper level of

lubricant recommended by the manufacturer.

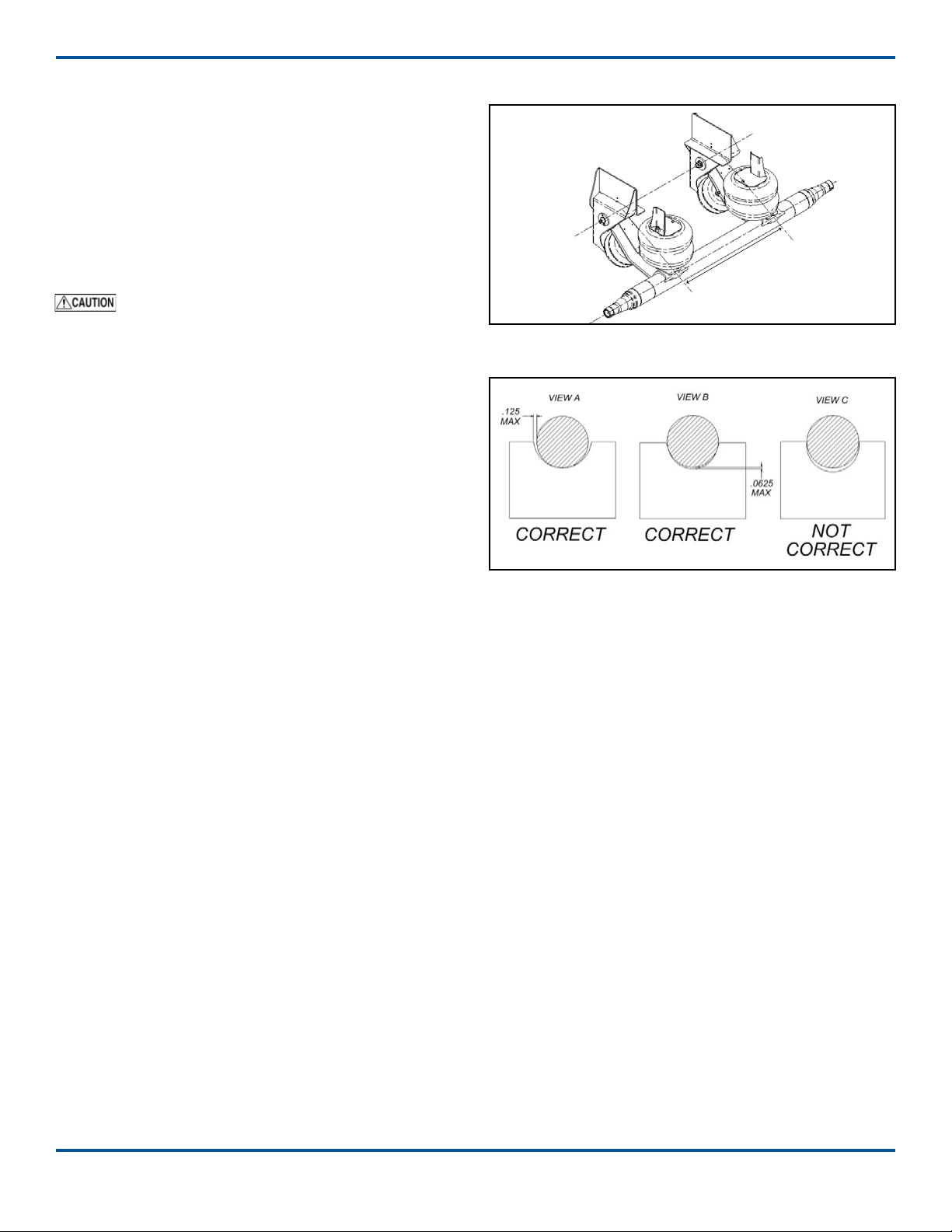

5. Lift the axle to the raised position. Check the air

system tubing and connections for leaks.

6. Check that wheels can rotate freely and that

brakes and slack adjusters are properly adjusted.

7. Raise and lower the suspension assembly (wheels

and tires installed) through the entire range of

travel. Make sure that sucient clearances for air

springs, brake chambers and other components

has been provided.

Do not lower the auxiliary axle while the

vehicle is moving above 10 mph.

Shock Absorber Kit (Optional)

The shock absorber can be installed after the suspen-

sion has been assembled and mounted on the vehicle.

Installation Procedure

Refer to the shock kit engineering drawing for the

correct mounting locations and installation angles for

the upper and lower mounting brackets on individu-

al RCA-215 suspension models.

Welding method for lower mounting bracket

must use a minimum weld tensile strength of 70,000

psi, per AWS specications.

1. Disconnect and remove the load springs from the

suspension assembly. Protect the lift springs from

welding spaer.

2. Remove the upper air spring mounting brackets.

continued on next page