918-I Heavy Duty Roll Grooving Machine

Ridge Tool Company6

6. Inspect the Roll Groover for any broken, missing,

misaligned or binding parts as well as any other con-

ditions which may affect the safe and normal oper-

ation of this equipment. If any of these conditions are

present, do not use the Roll Groover until any problem

has been repaired.

7. Lubricate the Roll Groover if necessary according

to the Maintenance Instructions.

8. Use groover rolls and accessories that are designed

for your Roll Groover and meet the needs of your ap-

plication. The correct groover tools and accessories

allow you to do the job successfully and safely. Ac-

cessories suitable for use with other equipment may

be hazardous when used with this Roll Groover.

9. Clean any oil, grease or dirt from all equipment han-

dles and controls. This reduces the risk of injury due

to a tool or control slipping from your grip.

10. Inspect the groove rolls to insure they are not dam-

aged or worn. Worn groover rolls can lead to pipe

slippage and poor quality grooves.

Machine and Work Area Set-Up

WARNING

To prevent serious injury, proper set-up of the ma-

chine and work area is required. The following

procedures should be followed to set-up the ma-

chine:

1. Locate a work area that has the following:

• Adequate lighting

• No flammable liquids, vapors or dust that may ignite.

• Grounded electrical outlet

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for machine and operator. Do not use

the machine while standing in water.

• Level ground

2. Clean up the work area prior to setting up any equip-

ment. Always wipe up any oil that may be present.

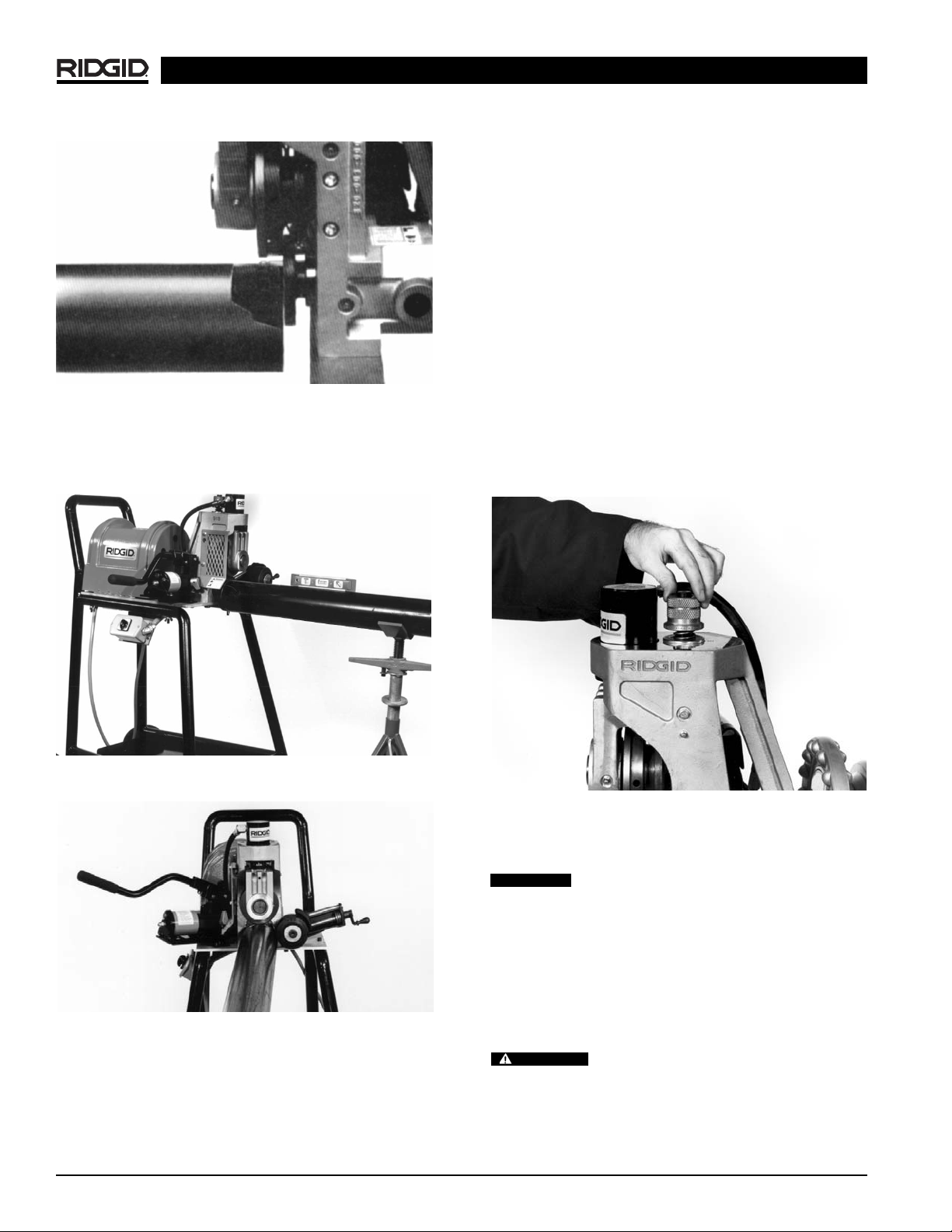

3. Place machine on a flat, level surface. Be sure the

groover and stands are stable. See Assembly In-

structions for bolting 918-I stand to shop floor.

4. Properly support the pipe with pipe stands. See Chart

“A” for maximum lengths with one (1) stand.

Failure to properly support the pipe can

result in the unit tipping or the pipe falling.

5. Make sure switch is in the OFF position.

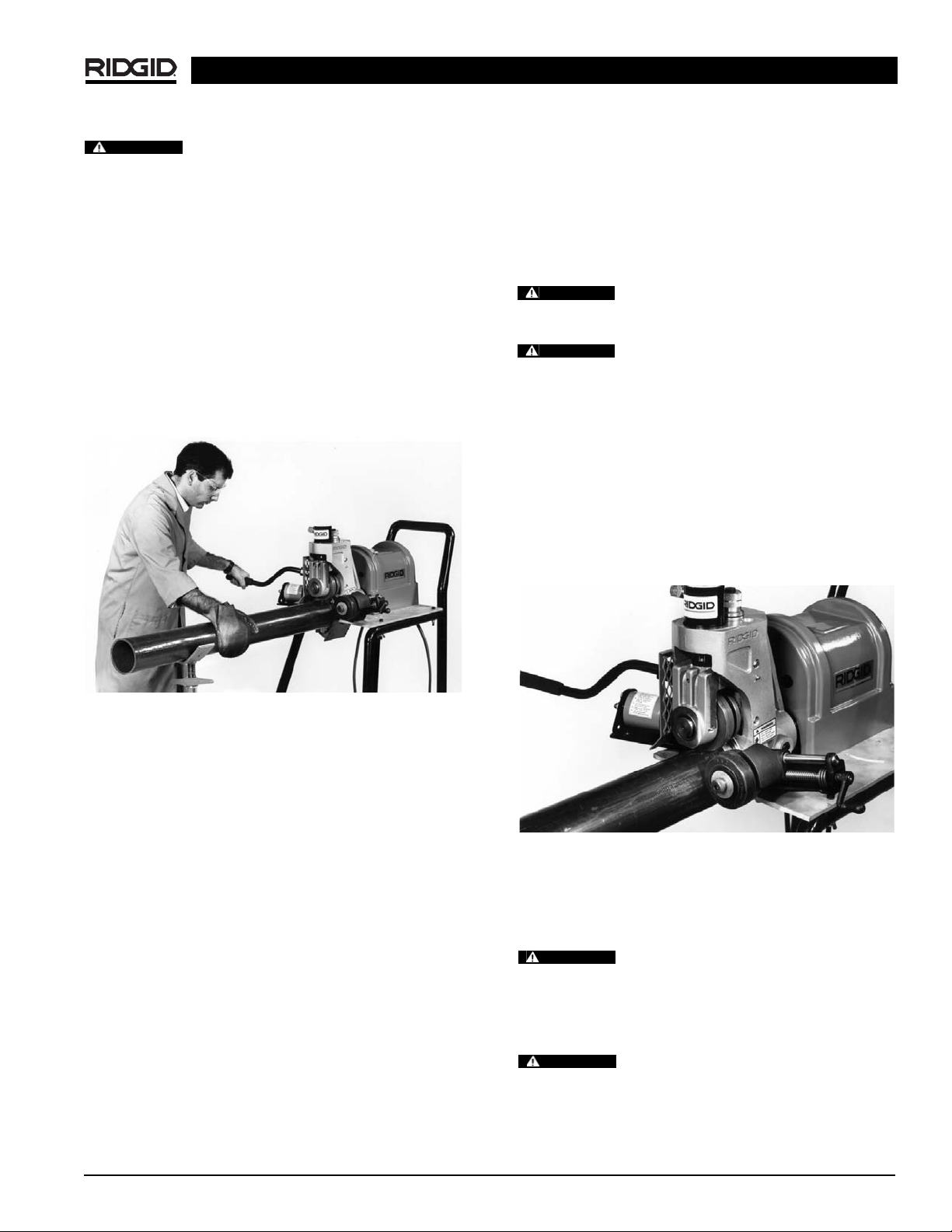

6. Position the foot switch so that the operator can

safely control the roll groover and workpiece. It should

allow the operator to do the following:

• Stand with left hand on pump handle.

• Use the foot switch with his left foot.

• Have convenient access to the groover without

reaching across the machine.

Machine is designed for one person operation.

7. Plug the machine into the electrical outlet making

sure to position the power cord along the clear path

selected earlier. If the power cord does not reach

the outlet, use an extension cord in good condition.

To avoid electrical shock and electrical

fires, never use an extension cord that is damaged or

does not meet the following requirements.

• The cord has a three-prong plug similar to shown in

Electrical Safety section.

• The cord is rated as “W” or “W-A” if being used out-

doors.

• The cord has sufficient wire thickness (14 AWG

below 25′/12AWG 25′- 50′). If the wire thickness is

too small, the cord may overheat, melting the cord’s

insulation or causing nearby objects to ignite.

To reduce risk of electrical shock, keep

all electrical connections dry and off the ground. Do

not touch plug with wet hands.

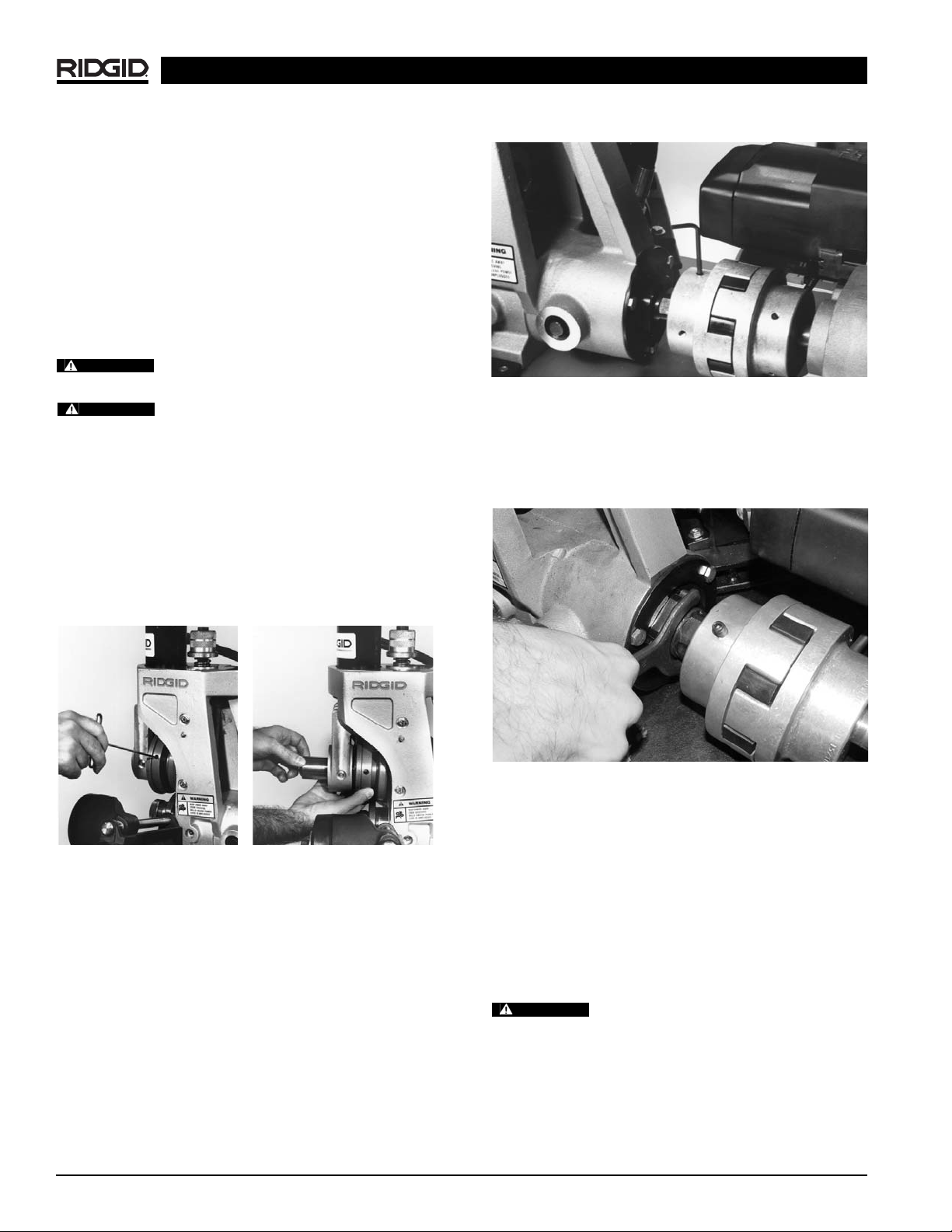

8. Check the unit to insure it is operating properly.

• Flip the switch to ON. Press and release the foot

switch. Check that the groove roll rotates in a clock-

wise direction as you are facing the groover. Have

the machine serviced if it rotates in the wrong di-

rection or if the foot switch does not control its

stopping or starting.

• Depress and hold the foot switch. Inspect the mov-

ing parts for misalignment, binding, odd noises or

any other unusual conditions that may affect the

safe and normal operation of the machine. If such

conditions are present, have the roll groover drive

serviced.

• Release the foot switch and flip the switch to OFF.

9. Check the groove and drive rolls to insure they are the

correct size.

WARNING

WARNING

WARNING