Ridge Tool Company4

•Never reach into the machine chuck or centering

head. This will reduce the risk of entanglement.

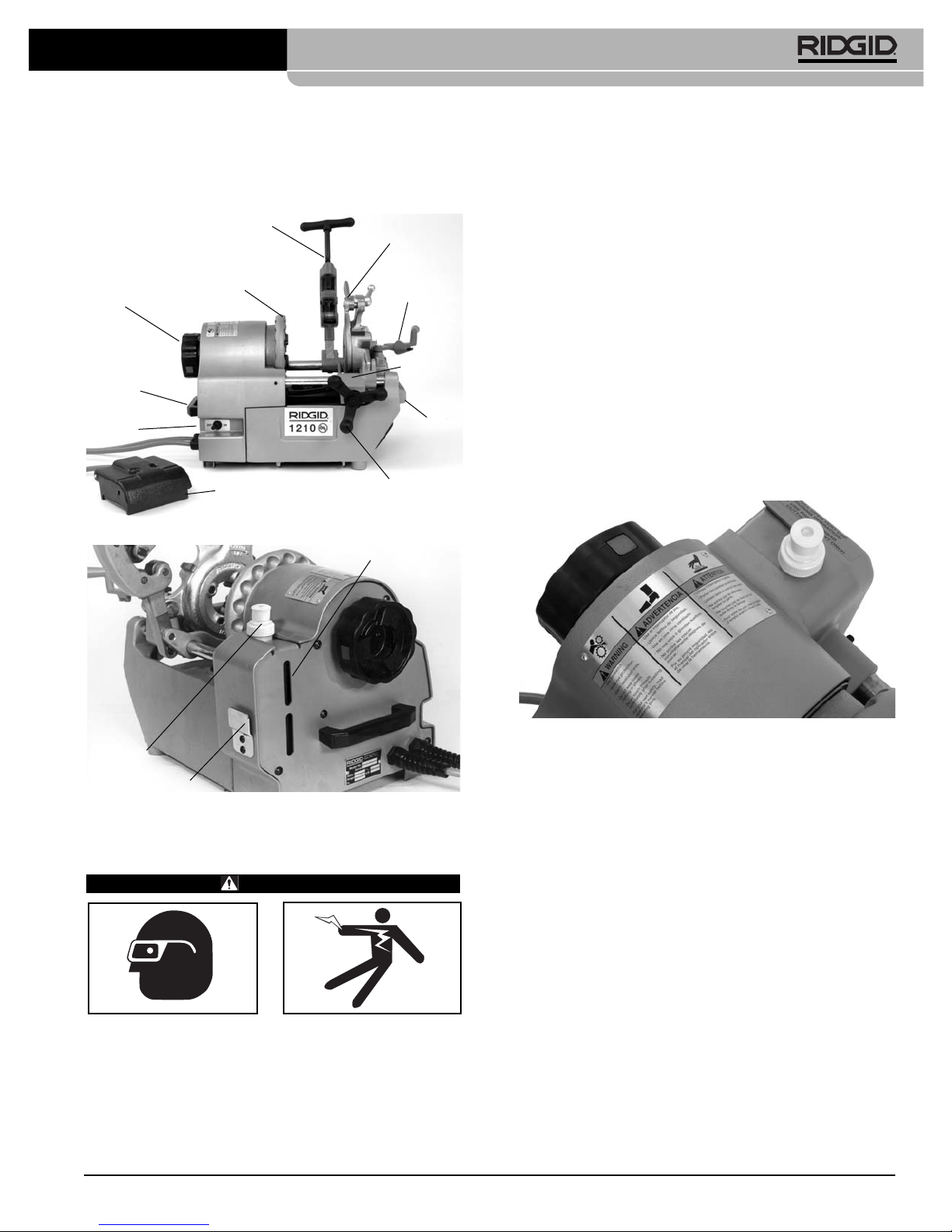

Description, Specifications and

Standard Equipment

Description

The RIDGID®Model 1210 Oil-less Threading Machine is

an electric motor-driven machine that centers and chucks

pipe and rotates it while cutting, reaming and threading

operations are performed. Threading dies are mounted

in a quick-opening die head. An integral coolant system

meters a specially formulated thread cutting fluid onto the

thread to reduce the temperature of the workpiece and lu-

bricate it during the threading operation.

Specifications

Threading Capacity .......Pipe 1/2" through 1"

Cut-Off Capacity............Pipe 1/2" through 1"

Operating Speed ...........25 RPM (No Load)

Motor:

Type ............................Universal

Volts ............................115V Single Phase AC

50/60 HZ

Amps ...........................6.4

Controls.........................ON/OFF Toggle Switch and

ON/OFF Foot Switch

Chuck ............................Hammer-Style with Replace-

able Inserts; Cam Action Rear

Centering Device

Coolant System.............16 Oz. Integral Coolant

Reservoir with Gerotor Pump

Weight ...........................59 lbs.

The 1210 Threading Machine is protected under U.S.

and international patents, including U. S. patent 5,826,469.

Standard Equipment

(Figure 1)

• Model 610 Quick-Opening Die Head, 1/2" – 1" NPT

•1/2"–

3/4" Oil-less Gold NPT Dies

• 1" Oil-less Gold NPT Dies

• Model 334 Blade-Type Reamer

• Model 354 Roll-Type, Self-Centering Cutter

• 1 Quart RIDGID Thread Cutting Coolant Fluid

Selection of appropriate materials and joining

methods is the responsibility of the system designer

1210 Oil-less Threading Machine

•Follow instructions on proper use of this machine.

Do not use for other purposes such as drilling

holes or turning winches. Other uses or modifying

this power drive for other applications may increase the

risk of serious injury.

•Do not use this machine to install or remove fit-

tings, it is not an intended use of the machine.

This practice could lead to trapping, entanglement and

loss of control.

•Secure machine to bench or stand. Support long

heavy pipe with pipe supports. This practice will

prevent tipping.

•Do not wear gloves or loose clothing when oper-

ating machine. Keep sleeves and jackets buttoned.

Do not reach across the machine or pipe. Clothing

can be caught by the pipe or machine resulting in en-

tanglement.

•While operating the machine, stand on the side

where the operator’s controls are located. Operating

the machine from this side eliminates need to reach

over the machine.

•Keep hands away from rotating pipe and fittings.

Stop the machine before wiping pipe threads or

screwing on fittings. Allow the machine to come to

a complete stop before touching the pipe. This

practice will reduce the chance of entanglement in ro-

tating parts.

•Keep covers in place. Do not operate the machine

with covers removed. Exposing moving parts in-

creases the probability of entanglement.

•Keep all electrical connections dry and off the

ground. Do not touch plugs or tool with wet hands.

These precautions will reduce the risk of electrical

shock.

•Keep floor dry and free of slippery materials such

as oil. Slippery floors invite accidents.

•Do not use this machine if the foot switch is broken

or missing. Foot switch is a safety device that provides

better control by letting you shut off the motor in various

emergency situations by removing your foot from the

switch. For example: if clothing should become caught

in the machine, the high torque will continue pulling you

into the machine. The clothing itself can bind around

your arm or other body parts with enough force to

crush or break bones.

•One person must control the work process, thread-

ing machine operation and foot switch. Only the

operator should be in the work area when the ma-

chine is running. This helps reduce the risk of injury.

NOTICE