2

Table of Contents

Section Page

Table of Contents .......................................... 2

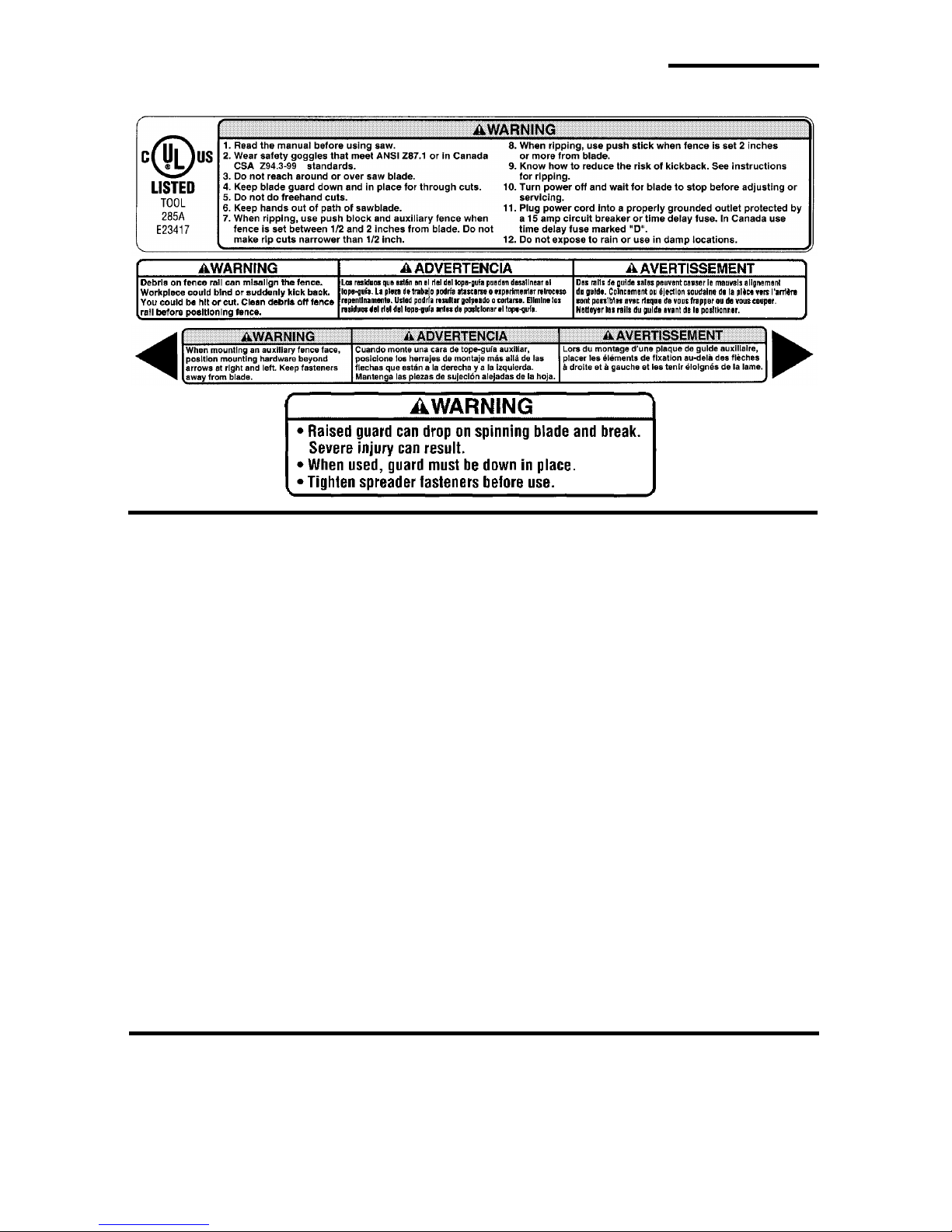

Safety Instructions For Table Saw ................3

Safety Signal Words .................................. 3

Before Using The Saw ............................... 3

When Installing Or Moving The Saw ............4

Before Each Use ........................................... 4

To Reduce theRisk of Injury From Jams,SlipsOr

Thrown Pieces (Kickbacks Or Throwbacks) ..5

Plan Ahead To Protect Your Eyes, Hands,

Face and Ears ............................................ 6

Whenever Sawblade Is Spinning ................. 7

Additional Safety Instructions For: Ripping ... 8

Additional Safety Instructions For: Crosscut . 9

Additional Safety Instructions For

Herc-U-Lift™ Caster System: ................... 9

Glossary of Terms for Woodworking .............9

Motor Specifications and Electrical

Requirements .........................................11

Power Supply and Motor Specifications ..11

General Electrical Connections ...............11

Changing Motor Voltage ..........................13

Motor Thermal Overload Protector ..........14

Wire Sizes ................................................14

Unpacking and Checking Contents .............15

Tools Needed ...........................................15

Unpacking .................................................15

List of Loose Parts ....................................16

Herc-U-Lift™ Caster Carton .....................17

Loose Parts ...............................................17

Assembly .....................................................17

Installing Handwheels ...............................17

Assembling Leg Stand ..............................18

Mounting Your Saw ..................................19

Assembling Table Extensions ...................20

Checking Table Insert ...............................21

Checking Heeling Adjustment or Parallelism

of Sawblade to Miter Gauge Groove ......22

Checking Blade Tilt, or Squareness of Blade

to Table ..................................................24

Checking Tilt Mechanism ..........................25

Assembling Herc-U-Lift™ Caster System .26

Assembly Tips ..........................................26

Upper Assembly .......................................26

Lower Assembly .......................................27

Assembling Herc-U-Lift™ Caster System to

Saw ........................................................28

Installation Instructions .............................28

Operation of Herc-U-Lift™ Caster System 29

Installing Front Rip Fence Guide Bar ........30

Installing Rear Fence Guide Bar ...............31

Adjusting Rip Fence Guide Bars ...............32

Installing Spacer Bar .................................33

Rip Fence Alignment Adjustment .............34

Rip Fence Lock Lever Adjustment ............34

Adjusting Fence Indicator .........................35

Installing Blade Guard ..............................35

Aligning Blade Guard ................................36

Section Page

Mounting the Motor ...................................37

Installing Belt ............................................38

Installing Belt Guard .................................38

Mounting Switch and End Caps ................39

Securing Electrical Cords .........................40

Installing Guide Bar End Caps ..................40

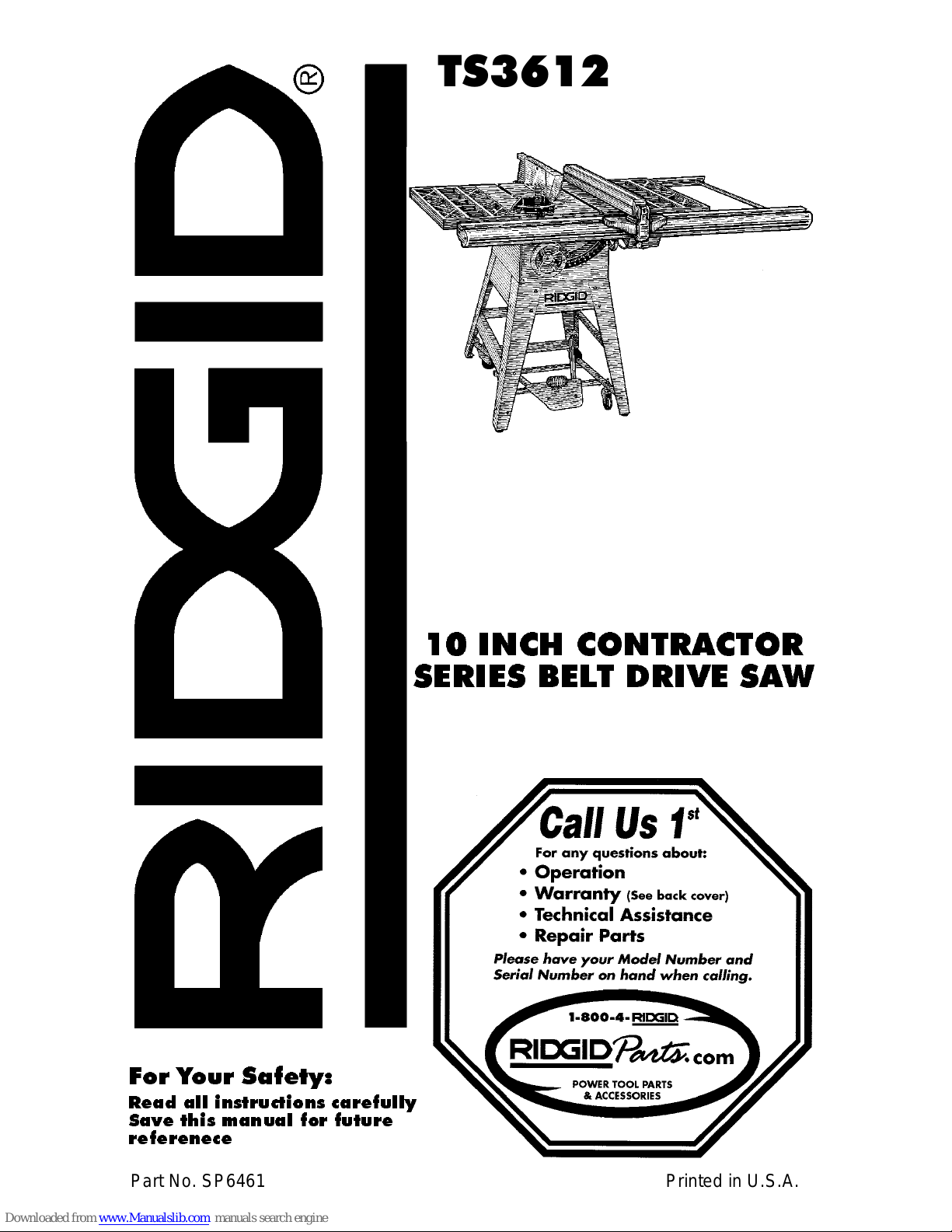

Getting to Know Your Table Saw ................41

Additional Safety Instructions When Using Zero

Clearance Insert......................................43

Remove the Existing Metal Insert..............43

Installing Zero Clearance Insert/Sawblade 43

Installing Zero Clearance Insert/Dado Blades44

Operation Tips ..........................................45

Safety Instructions for Basic Saw Operations 48

Before Each Use .........................................48

ToReducethe Risk of Injury From Jams, SlipsOr

Thrown Pieces (KickbacksOr Throwbacks) 48

Plan Ahead To Protect Your Eyes, Hands,

Face and Ears ..........................................49

Whenever Sawblade Is Spinning .............50

Work Feed Devices .....................................51

Attaching Wood Face Board .....................51

Push Block ................................................52

Auxiliary Fence .........................................53

Fence Extension........................................54

Basic Saw Operations .................................55

Using the Miter Gauge ..............................55

Additional Safety Instructions for Crosscutting 55

Crosscutting ..............................................55

Repetitive Crosscutting .............................56

Miter Crosscutting .....................................57

Bevel Crosscutting ....................................57

Compound Crosscutting ...........................57

Using the Rip Fence .................................58

Additional Safety Instructions for Rip Cuts 58

Ripping ......................................................59

Bevel Ripping Narrow Work ......................60

Using Featherboards for Thru-Sawing ......61

Using Featherboards for

Non Thru-Sawing ....................................61

Resawing ..................................................62

Using Carbide Tipped Blades ...................63

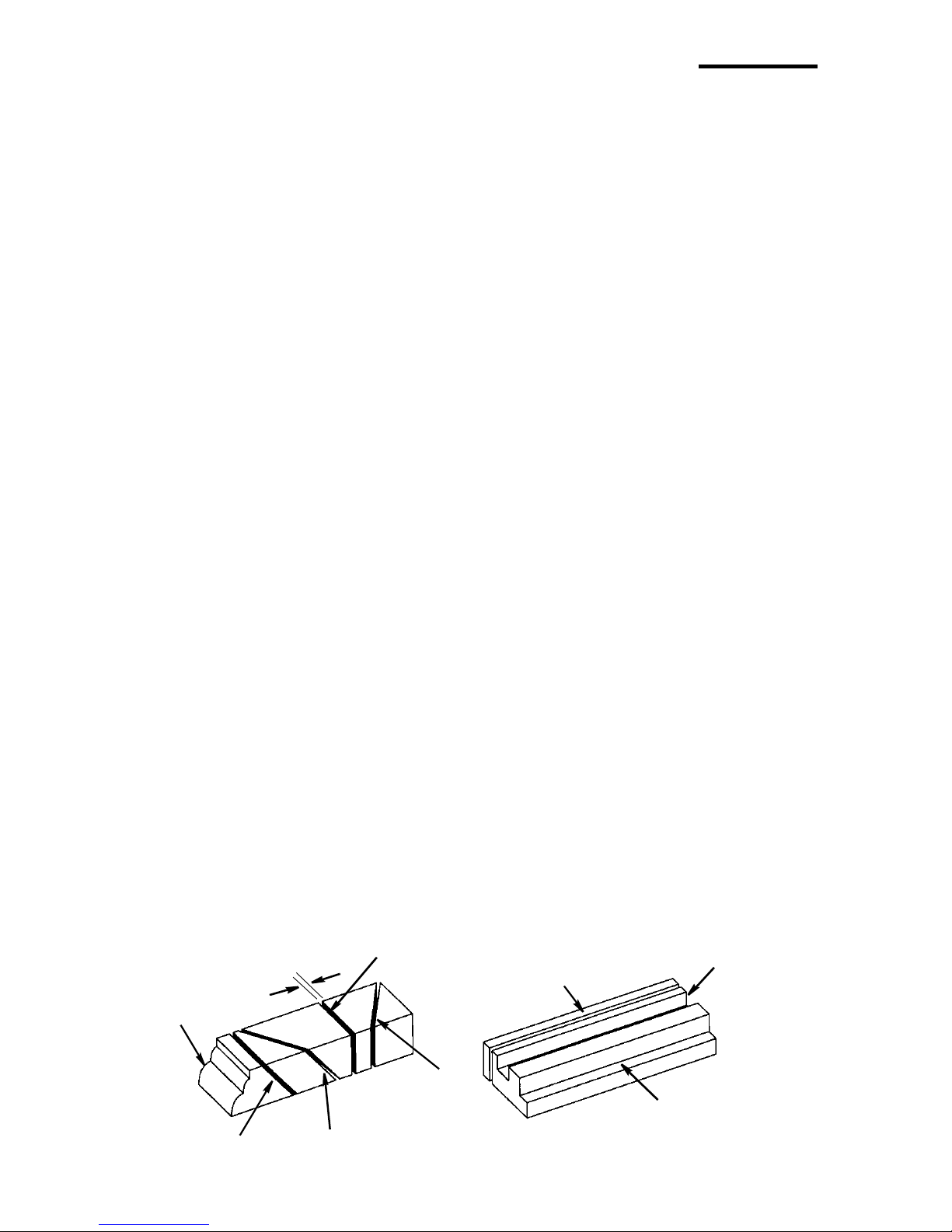

Dadoing ....................................................63

Rabbeting .................................................64

Ploughing and Molding .............................64

Molding .....................................................65

Adjustments .................................................66

Miter Gauge ..............................................66

Maintaining Your Table Saw .......................67

Maintenance .............................................67

Lubrication ................................................68

RIDGID Recommends the Following

Accessories ............................................68

Troubleshooting ...........................................69

General .....................................................69

Motor .........................................................70

Repair Parts ................................................72