•Never hold the workpiece in your hands or across

your leg while cutting. Always secure the work

piece in an appropriate pipe vise and properly

support. It is important to support the work properly to

minimize body exposure, blade binding, equipment

and material falling or loss of control.

•Do not start the saw with the saw blade touching

the work piece. et the blade reach full speed

before carefully feeding it into the work piece. The

blade may bind, walk or kickback if the tool is started

with the blade in contact with the work piece.

•Do not reach into the chip chute. Do not insert

tools or other objects into the chip chute. Do not

block chip chute. This will reduce the risk of cutting,

entanglement and striking injuries.

•Do not reach inside the pipe. The guard cannot

protect you from the blade inside the pipe.

•During set-up, always confirm the saw is locked in

position on the clamp with the clamp 10 degrees

from vertical. This will reduce the risk of unintended

movement of the saw during use.

•Be aware that the saw gear box can be hot from

use. Do not touch gearbox during or after operation to

reduce the risk of burns.

•Properly route and position the cord during use to

reduce the risk of cord damage and electrical

shock. If the cord is cut, the saw, pipe or other objects

may be electrically charged. Make sure the saw is

controlled and unplug the cord from the outlet.

•Read and understand these instructions and the

instructions and warnings for all equipment and

materials being used before operating this tool to

reduce the risk of serious personal injury.

•Do not modify PipeSaw or use for any other pur-

pose. Other uses or modifying the saw for other appli-

cations may damage the tool, damage the attachments

and/or cause personal injury.

•Only cut empty pipe. Do not cut pipe with any type of

contents to reduce the risk of electrical shock and

other hazards.

•Avoid breathing of dust created from pipe cutting.

Some dust created may contain chemicals known to

cause cancer, birth defects or other serious personal

injury. Consider the pipe material and coatings when

determining appropriate respiratory protection, includ-

ing things such as lead based paint.

Your risk from these exposures varies, depending on

how often you do this type of work and the concen-

tration of dust. To reduce your exposure to these chem-

Specic Safety Information

WARNING

This section contains important safety information

that is specic to this tool.

Read these precautions carefully efore using the

PCS-500 Transporta le Pipe Saw to re duce the risk

of electrical shock or other serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

Keep this manual with machine for use by the operator.

PipeSaw Safety

Keep hands away from cutting area

and blade. Allow parts to come to a complete stop

before handling the tool or pipe. This will reduce the

risk of cutting and entanglement injuries.

•Keep your hands on saw handles and firmly control

during use. This provides better control of the machine

and cutting process. If both hands are holding the saw,

they cannot be cut by the saw blade.

•Always wear appropriate eye protection and hear-

ing protection. Cutting tools can break or shatter.

Cutting produces chips that can be thrown or fall into

eyes. Cutting produces high noise levels that over

time can damage your hearing.

•Always wear appropriate personal protective equip-

ment. Face shields, long sleeves, safety shoes, hard

hat, and other equipment as appropriate will reduce the

risk of injury.

•Do not wear loose clothing when operating PCS-500

Transportable Pipe Saw. Keep sleeves and jackets

buttoned. Do not reach across machine. Clothing can

be caught by the machine resulting in entanglement.

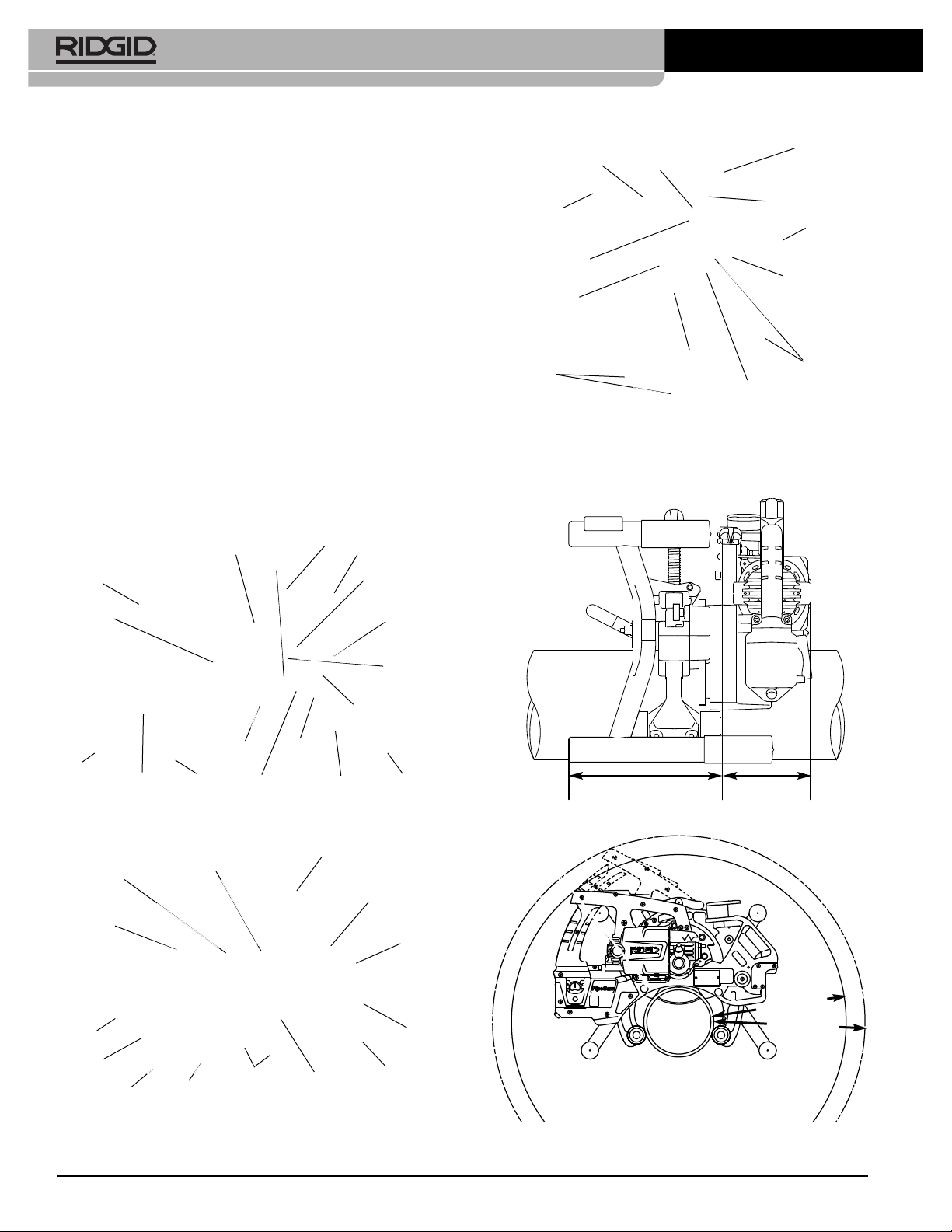

•Keep bystanders clear of work area. Guard or bar-

ricade minimum of 9 feet (2.7 meter) around the

working area. Chips or broken saw teeth can be thrown

and cause injury beyond immediate area of operation. A

guard or barricade that provides a clearance around the

work piece will reduce the risk of injury.

•One person must control the work process and the

saw ON/OFF switch. Only the operator should be in

the work area when the machine is running. This helps

reduce the risk of injury.

•Properly support work piece and PipeSaw Trans-

portable Pipe Saw. Make sure the saw clamp is

secure to the work piece. This will reduce the risk of

striking and crushing injuries from tipping and falling

pipe and equipment.

999-995-226.10 REV. A4

PCS-500 Pi eSaw

DANGER