3D Laser measurement machine, RF1010SS

RF1010SL [Document version 1.0] December 30th 2012

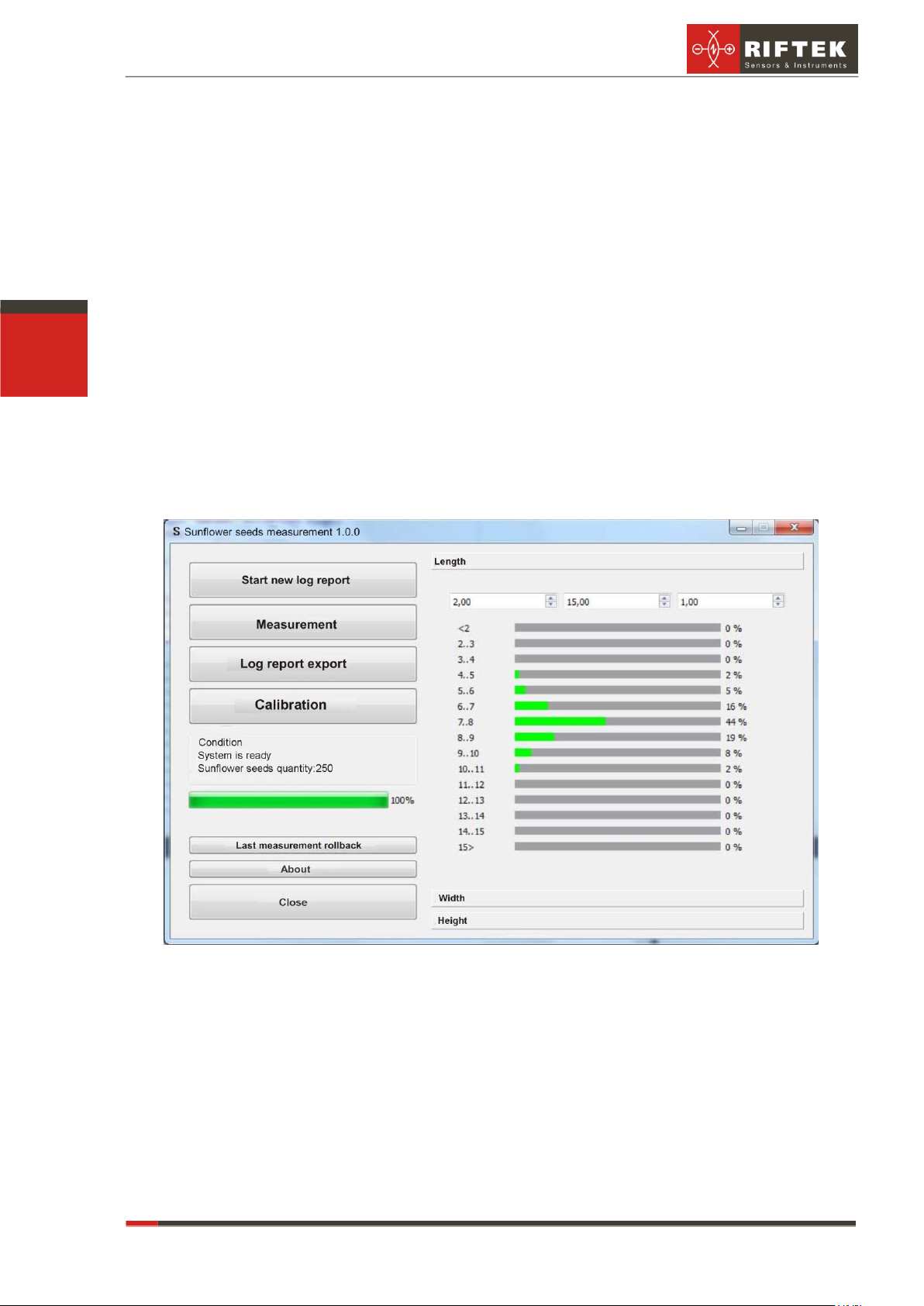

9.4. Calibration

For the first start of the machine and once a month it is recommended to cali-

brate the machine. To do this, remove all items from the working surface of the machine

table and click Calibration. When the system status changes (e.g., because of transpor-

tation, reassembly), calibration must be carried in a mandatory manner.

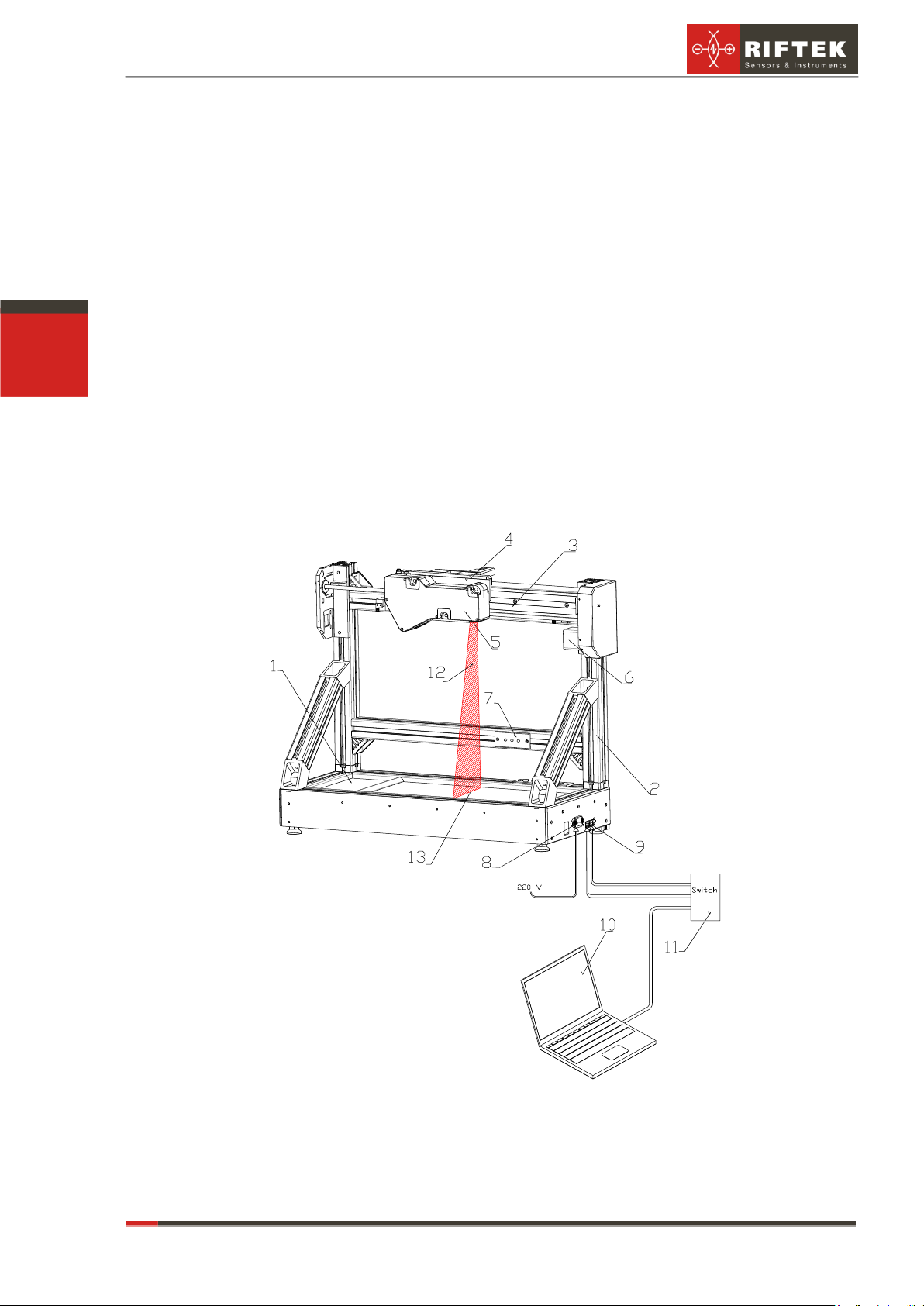

9.5. Indicating lights

The indicating lights (see. Fig. 1) show the current status of the machine.

Red LED is lit –failure;

Blue LED is lit –machine is ready for operation

Yellow LED is lit –scanning is in process

10. Maintenance

10.1. General instructions

Maintenance of the machine is carried out to ensure constant-ready status and

continued availability of its work and to prevent premature failure.

10.2. Maintenance procedure

10.2.1.Daily maintenance work

Daily maintenance includes:

Visual inspection of the machine,

Checking of completeness,

Inspection of the units and elements that make up the machine,

Checking for any damage of the structural elements, power and instrument

cables, indicators and connectors,

weakening of screw connections and insulation failures,

Before starting work, it is necessary to wipe the input and output laser scan-

ner windows with a soft dry cloth.

10.2.2.Weekly maintenance work

Weekly maintenance includes:

cleaning of laser scanner windows with a dry soft lint-free cloth from contami-

nation or dirt;

checking of free movement of the carriage

10.2.3.Yearly maintenance work

Authenticated calibration of the laser scanner should be made once a year

11. Routine repairs

Trouble-shooting instructions are given in the following table.

Effects of extraneous illumination source

Remove extraneous illumination source

or protect the machine against its ef-

fects

Dirty laser scanner windows

Seeds are in touch with each other

Fulfill condition in par. 8.1.