6310338

System Information

System Description

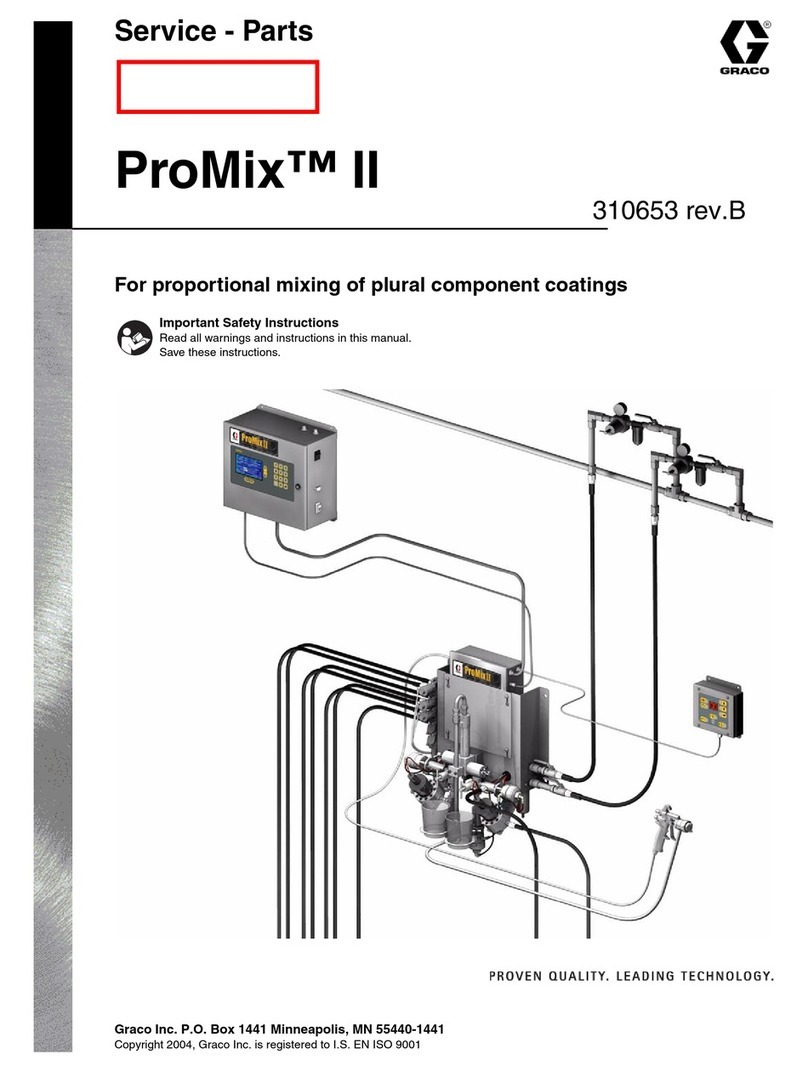

Systems 970196 and 970197 include dual 55 gallon

supply units for continuous material supply. System

970196 uses a pneumatic crossover; System 970197

uses an electrical crossover.

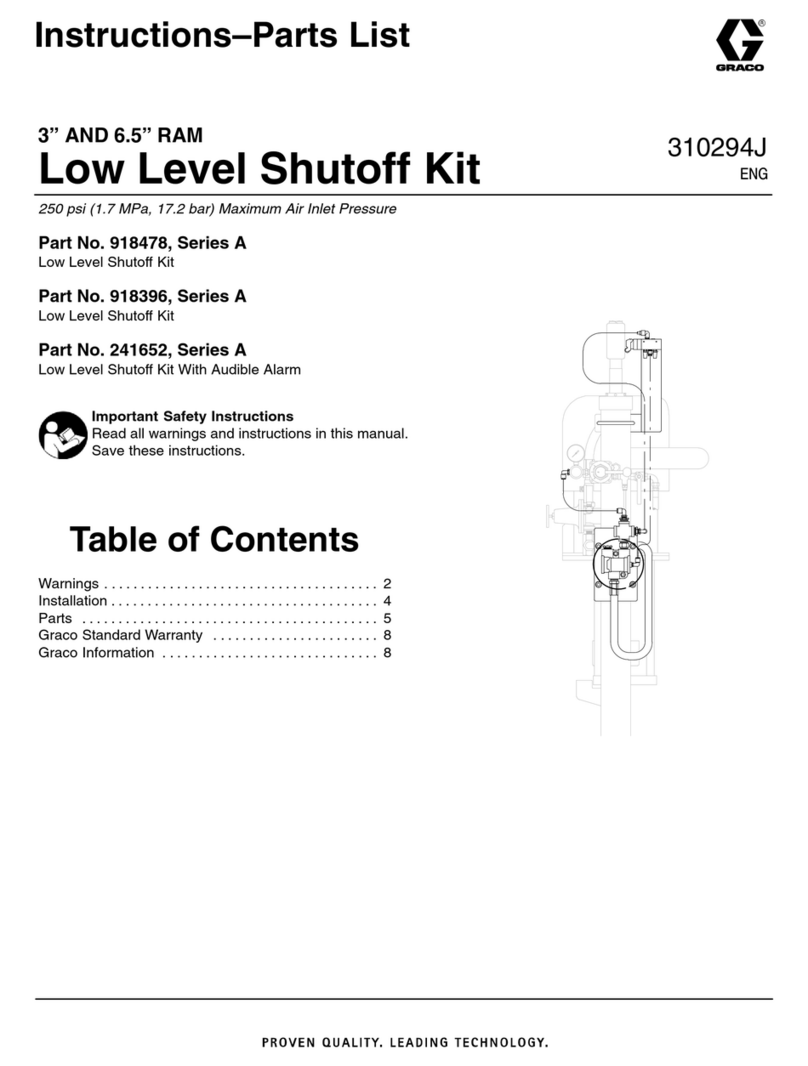

System 970198 is a single 55 gallon supply unit with a

low–level shutoff. See Fig. 1.

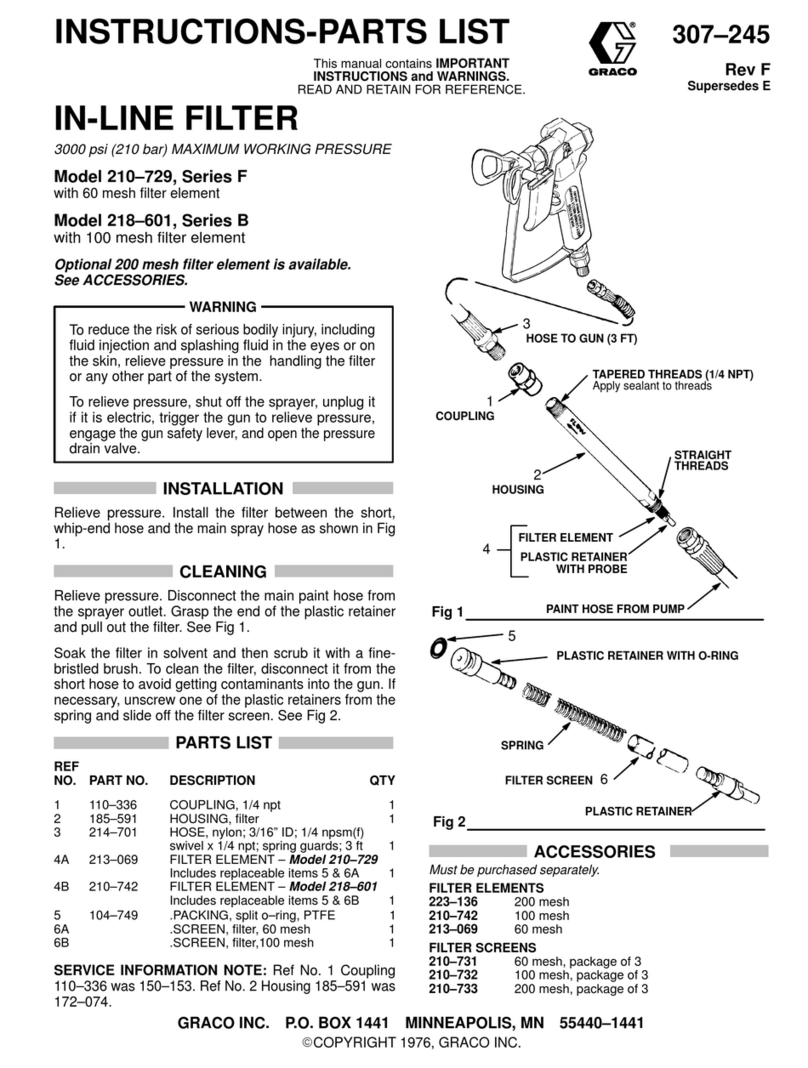

Each system air–powered ram pushes a ram plate (C)

into a drum of material, while the pump (A) removes

material from the drum and pushes it through a supply

hose to a customer–supplied header. Material flows

through the header to individual dispense drops.

WARNING

A main air bleed valve (E) and pump air bleed

valve (H), are required. These accessories help

reduce the risk of serious injury, including fluid

injection and splashing of fluid in the eyes or on the

skin, and injury from moving parts if you are adjust-

ing or repairing the pump.

The main air bleed valve (E) shuts off and relieves

the air to the pump and ram. The ram will hold

pressure if the ram director valve (U) is in the

horizontal (neutral) position. To relieve air pressure

in the ram, close the main air bleed valve (E) and

move the director valve (U) to DOWN. The ram will

slowly drop.

The pump air bleed valve (H) relieves air trapped

between it and the pump after the air is shut off.

Trapped air can cause the pump to cycle unexpect-

edly. Locate the valve close to the pump.

The fluid drain valve assists in relieving fluid pres-

sure in the displacement pump, hose, and gun.

Triggering the gun to relieve pressure may not be

sufficient.

System Accessories and Modules

Before you install the system, you should be familiar

with the parts discussed in the following paragraphs.

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing.

DMain air bleed valve (E) is required in your system

to shut off the air supply to the pump and ram

(Refer to the preceding WARNING ). When closed,

the valve bleeds off all air in the ram and pump, and

the ram slowly lowers. Be sure the valve is easily

accessible from the pump, and is located upstream

from the air manifold (F).

DPump air bleed valve (H) is required in your

system to relieve air trapped between it and the air

motor when the valve is closed (Refer to the pre-

ceding WARNING). Be sure the valve is easily

accessible from the pump, and is located down-

stream from the air regulator (G).

DAir regulator (G) controls pump speed and outlet

pressure by adjusting the air pressure to the pump.

Locate the regulator close to the pump, but up-

stream from the pump air bleed valve.

DAir manifold (F) has a swivel air inlet. It mounts to

the ram, and provides ports for connecting lines to

air-powered accessories.

DAir line filter (J) removes harmful dirt and moisture

from the compressed air supply.

DSecond bleed-type air valve (K) isolates the air

line accessories for servicing. Locate upstream

from all other air line accessories.

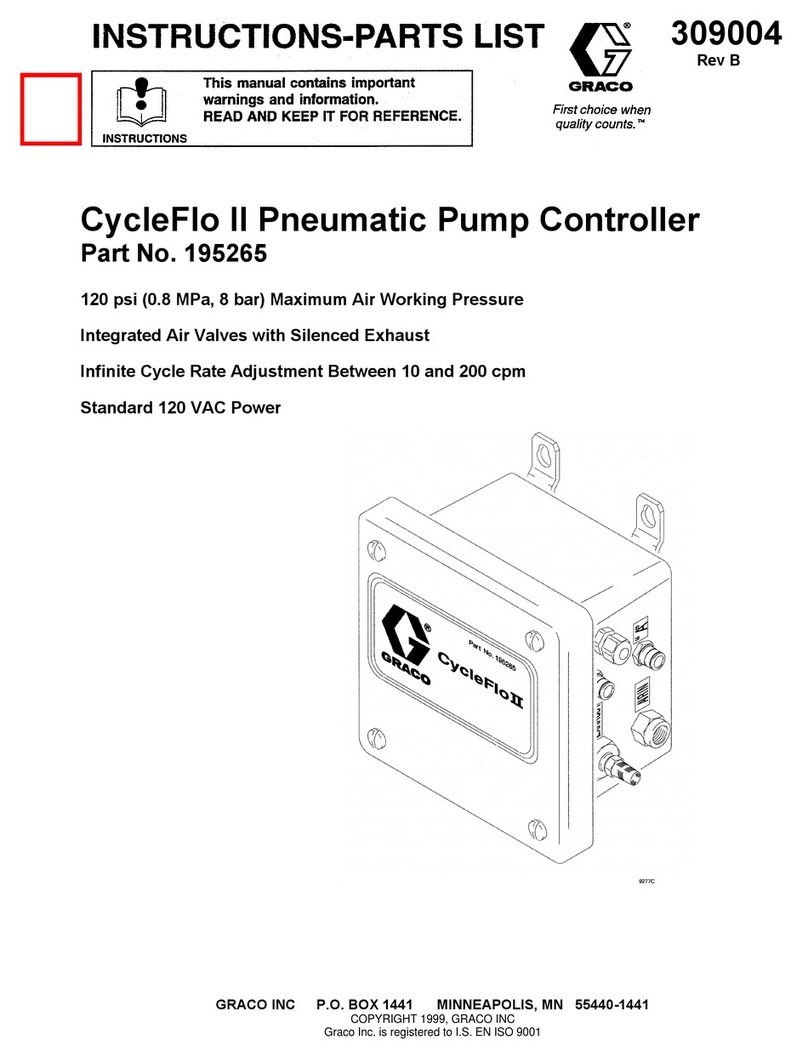

DPneumatic (Model 970196) or electrical (Model

970197) crossover (L) provides switching between

dual rams to provide a constant supply of material

to the system. The crossover controls the air supply

to each of the ram air motors. A low–level shutoff

(L) (Model 970198) provides automatic shutdown

of a single ram system when only a small amount

of material remains. The shutoff controls the air

supply to the ram air motor.

DRam air regulator (T) controls the air pressure to

the ram.

DRam director valve (U) controls the raising and

lowering of the ram.

DAir release valve (V) opens and closes the flow of

air to assist raising the ram plate (C) out of an

empty drum.

DBleed handle (CC) bleeds air from under the ram

plate (C) to assist in priming the pump and lowering

the ram plate into the drum.