3

Contents

1.0 Introduction ..............................3

2.0 Safety ..................................3

2.1 General safety ............................3

2.2 Danger .................................3

3.0 Field of application. . . . . . . . . . . . . . . . . . . . . . . . .3

3.1 Handling ................................4

3.2 Technical data ...........................4

4.0 Transport, handling and storage ..............4

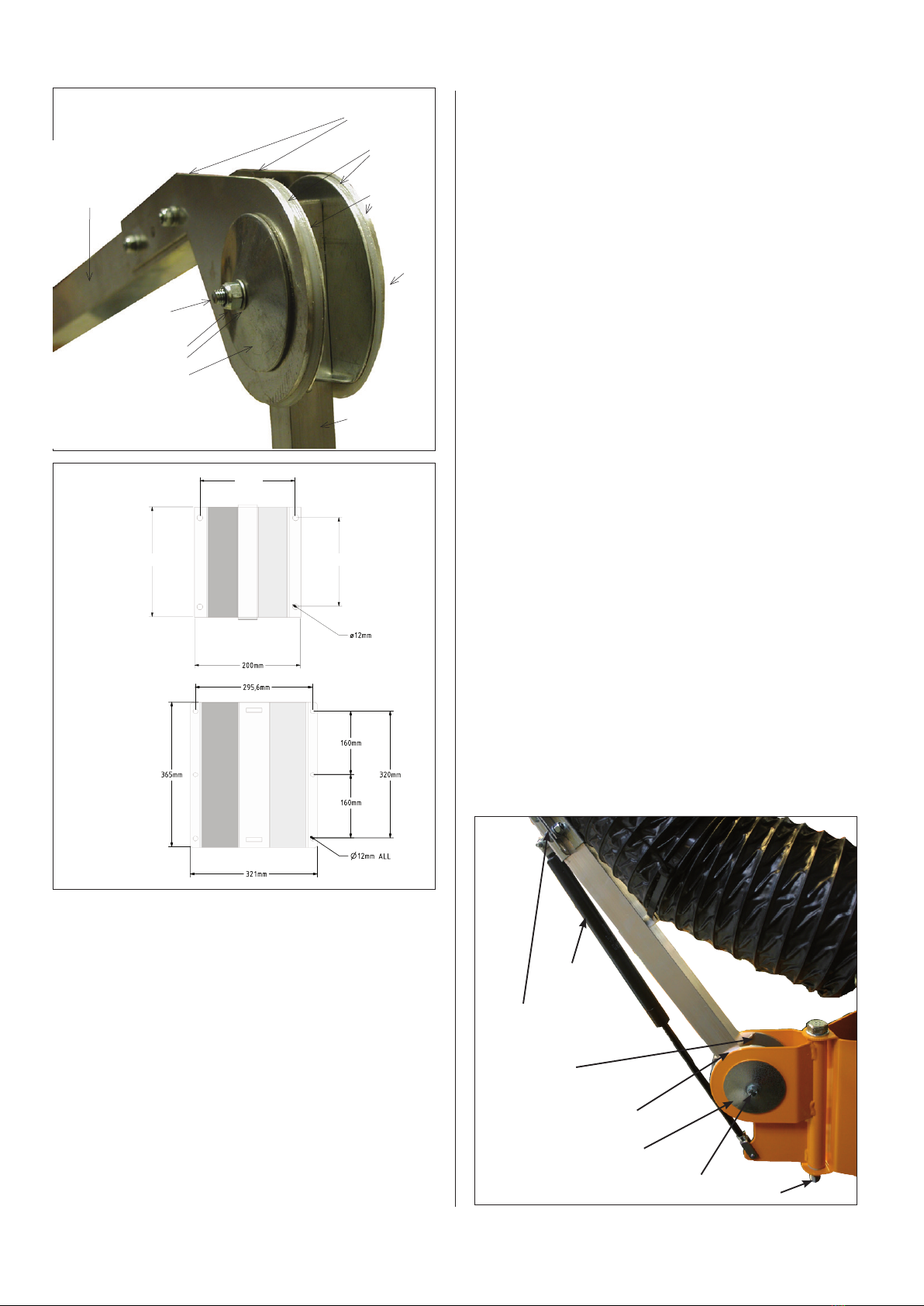

5.0 Construction .............................4

5.1 Installation ..............................4

5.2 Mounting of optional equipment ..............5

5.3 Trial run – exact adjustment .................6

6.0 User instruction – application ................6

7.0 Dismantling, disabling and scrapping ..........6

8.0 Dimensions ..............................6

9.0 Liability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

10.0 Declaration of conformity...................7

1.0 Introduction

This manual is made and designed in order to facilitate

the best and most secure interaction with the product.

The manual is relevant for people involved in transpor-

tation, stocking, installation, using, maintaining and all

other thinkable interaction with the product.

The manual must be read in full and understood before

interacting with the product.

When the manual has been read and understood in full,

the table of contents can be used to find the relevant

information in each case.

The product is manufactured by:

Geovent A/S

Hovedgaden 86

DK-8861 Løgstrup

DENMARK

Tel.: (+45) 86 64 22 11

www.geovent.com

This manual is to be used for all interactions with the

product including: Transportation, stocking, installation,

operation and maintenance.

2.0 Safety

2.1 General safety

Carefully read this manual before use and observe the

safety instructions in order to avoid injuries!

Keep this manual in a safe place!

Secure that all users of the product have read this ma-

nual and that they follow the instructions as described.

Observe all instructions marked on the product!

Observe the indications of the manufacturer.

Never use the product if you are in doubt about how it

works or what you should do.

When doing maintenance follow the instructions in chap-

ter 7.0.

Do not modify the product or use spare parts from other

suppliers than Geovent, as this may hamper the product

and the function.

2.2 Danger

You must wear safety gloves when handling or using the

product to protect your hands from scratches etc.

Be aware that the product may tilt when you move it.

You must handle the product with care and tie it safely to

the truck or the fork lift when it is in transport.

When handling the product be sure that the there is no

risk for the installer, and secure that there are no people

around the product, secure that the product cannot fall

down risking to injure persons or subjects.

In case of an accident or a fire:

Call for help.

The product is not to be used in areas categorised as

ATEX zones, e.g. with dust from aluminium, flour, wood,

and other mediums that present an explosion hazard.

If a repair is not possible you should dispose of the pro-

duct. Please follow the instruction for disposal in chapter

10.0.

3.0 Field of application

The ASA-3 Arm is the ideal Extraction Arm for the extra-

ction of welding smoke, grinding dust, fumes, etc., whe-

re the well-being of the operator is in focus with regard to

lightness, ergonomics and efficiency of the Arm.

The Extraction Arm is not suitable for the extraction of

aluminium dust, flour, textile dust nor sawdust or other

media, which are connected with danger of explosion,

without specific approval from Geovent A/S.

The hose may be damaged and leaky via outer loads,

e.g. by a screw driver. Avoid such load in order to safe-

guard a long life.

Art. No. Description

74-480 ASA-HV50 Arm for High Vacuum 2 m. ø50

74-481 ASA-HV50 Arm for High Vacuum 3 m. ø50

74-482 ASA-HV50 Arm for High Vacuum 4 m. ø50

74-483 Mini-HV50 Arm for High Vacuum 1 m. ø50

74-484 Mini-HV50 Arm for High Vacuum 1,5 m. ø50

74-485 Muffled HV hood with magnet