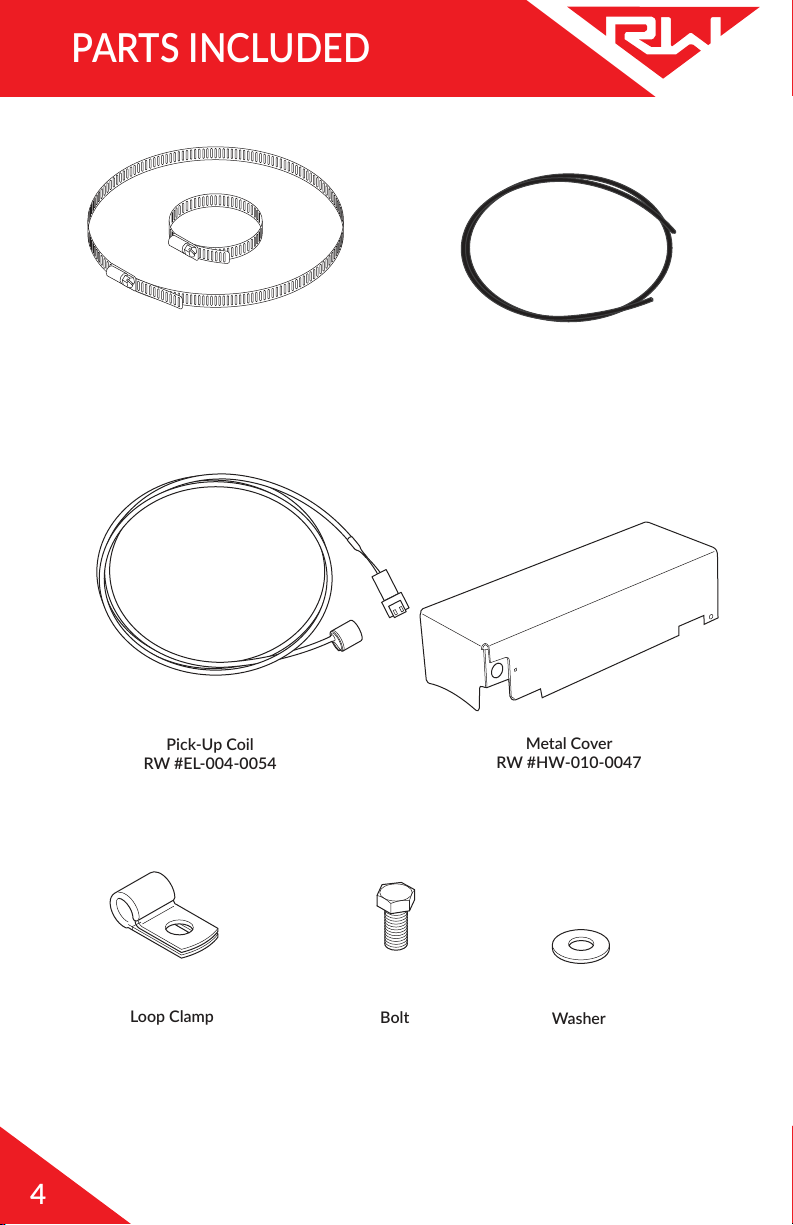

AXLE PREPARATION

FIND THE CENTER OF THE AXLE

PLACE WELDING JIG ON AXLE

CLEAN WELD AREAS

2

1

3

Use the tape measure to find the

center of the axle and mark locaon

with a marker. For walking beam axles,

find a point about midway between

the pivot point of the equalizing

walking beam and the aachment

point of the axle. Please refer to the

corresponding Installaon Overview

for specific placement of sensors.

Place the Welding Jig Assembly

on the axle so that it is centered

over the line. Draw circles

around where the mounng

blocks will be located. Remove

from axle.

Use the angle grinder or sander

to clean the metal in the circles

to be welded. Make sure the

area is free of paint, dirt, rust,

and any other debris.

AXLE

8

AXLE

AXLE

MOUNTING

BLOCK

WELDING JIG

ASSEMBLY

!

WARNING!

Please refer to the corresponding Installaon Overview for

specific placement of sensors before beginning.

Please check your vehicle manufacturer’s recommendaons

regarding welding before beginning.

The sensor must be

placed on the TOP

of the axle

!