Operating Precautions

- 1 -

<Contents>

1 Outline of the Product ..................................................................................................... 2

1-1. Preface ........................................................................................................................... 2

1-2. Purpose of use ............................................................................................................... 2

1-3. Definition of DANGER, WARNING, CAUTION, and NOTE ............................................ 2

2 Important Notices on Safety............................................................................................ 3

2-1. Danger cases ................................................................................................................. 3

2-2. Warning cases................................................................................................................ 4

2-3. Precautions..................................................................................................................... 5

2-4. Safety information........................................................................................................... 6

3 Product Components ...................................................................................................... 7

3-1. Gas detector and standard accessories ......................................................................... 7

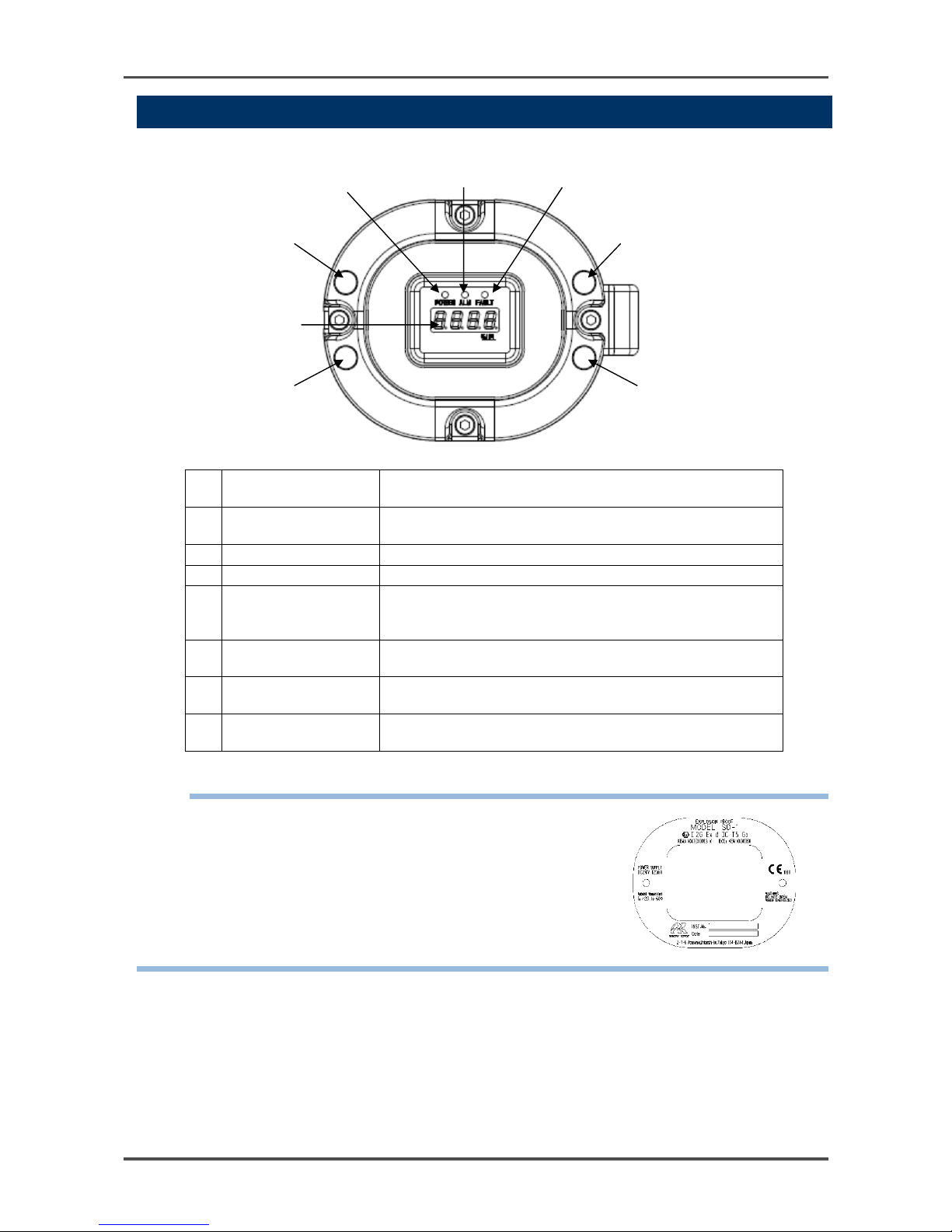

3-2. Names and functions for each part................................................................................. 8

3-3. Block diagram................................................................................................................. 9

4 How to Use...................................................................................................................... 10

4-1. Before using the detector................................................................................................ 10

4-2. Precautions for installation points ................................................................................... 10

4-3. Precautions for system designing................................................................................... 11

4-4. How to install .................................................................................................................. 13

4-5. How to wire..................................................................................................................... 14

5 How to Operate ............................................................................................................... 19

5-1. Preparation for start-up................................................................................................... 19

5-2. Basic operating procedures............................................................................................ 19

5-3. How to start the detector ................................................................................................ 20

5-4. Modes............................................................................................................................. 21

5-5. User mode ...................................................................................................................... 22

5-6. How to exit...................................................................................................................... 24

6 Operations and Functions ............................................................................................... 25

6-1. Gas alarm activation....................................................................................................... 25

6-2. Fault alarm activation ..................................................................................................... 26

6-3. External output operation................................................................................................ 27

6-4. Other functions ............................................................................................................... 28

7 Maintenance.................................................................................................................... 29

7-1. Maintenance intervals and items .................................................................................... 29

7-2. Regular maintenance mode............................................................................................ 31

7-3. Gas calibration method................................................................................................... 38

7-4. Parts replacement .......................................................................................................... 41

7-5. Expiration date of Japan Gas Appliances Inspection Association certification product... 41

8 Storage, Relocation and Disposal ................................................................................... 42

8-1. Procedures to store the detector or leave it for a long time ............................................ 42

8-2. Procedures to relocate the detector or use it again ........................................................ 42

8-3. Disposal of products ....................................................................................................... 42

9 Troubleshooting............................................................................................................... 43

10 Product Specifications .................................................................................................... 45

10-1. List of specifications ........................................................................................................ 45

10-2. List of accessories........................................................................................................... 48

10-3. Detection principle........................................................................................................... 49

11 Definition of Terms........................................................................................................... 51