Replacement Parts

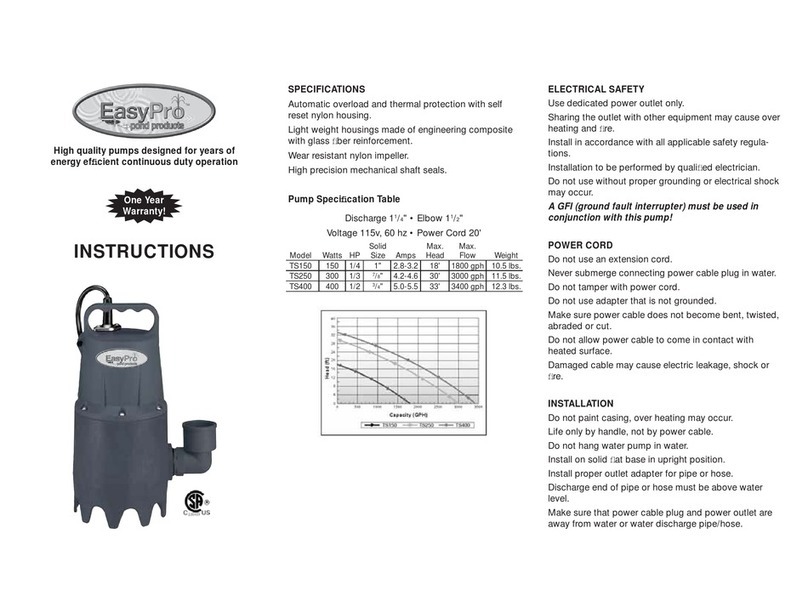

WARNING: The following may cause severe damage to pump and will void warranty:

• Using an extension cord

• Cutting o the ground pin or using an adapter tting

• Working on pump or switch while plugged in

• Removing motor housing, unscrewing impeller or otherwise removing impeller seal

• Pumping chemicals or corrosive liquids

• Pumping gasoline or other ammable liquids

• Piping: Plastic PVC pipe, drain hose, galvanized steel or copper pipe may all be used. All piping must

be clean and free of all foreign matter to prevent clogging. Use thread compound on all threaded joints

unless specied otherwise. Be sure to seal the thread connection with tape seal when you are using the

pipe tting to connect the ange.

Troubleshooting

Problem

Pump hums

Pump runs but does

not deliver water

Pump runs but

delivers only a small

amount of water

Fuse blows or circuit

breaker trips when

pump starts

Motor runs for a short

time, then stops

Possible Causes

• Line circuit breaker is o, or fuse is burned or loose.

• Water level in sump has not reached turn-on level as indicated in installation drawing on the carton.

• Pump cord is not making contact in receptacle.

• Float (optional) is stuck. It should operate freely in basin.

• If all of the above are OK and then the motor should operate.

• Check valve (optional) is installed backwards (not included with pump), arrow on valve should point in direction of

ow.

• Discharge shut-o valve (if used) may be closed.

• Impeller or volute openings are fully or partially clogged, remove pump and clean.

• Pump is air-locked, start and stop several times by plugging and unplugging cord, check for clogged vent hole in

pump case.

• Inlet holes in pump base are clogged, remove pump and clean the openings.

• Vertical pumping distance is too high or the pipe size is too small, reduce vertical distance or increase the pipe size

ttings.

• Pump is air-locked, start and stop several times by plugging and unplugging cord, check for clogged vent hole in

pump case.

• Vertical pumping distance is too high or pipe size is too small, reduce vertical distance or increase the pipe size.

• Inlet holes in pump base are clogged, remove pump and clean the openings.

• Impeller or volute openings are fully or partially clogged, remove pump and clean.

• Pump impeller is partially clogged with debris, causing motor to run slow and overload, remove pump and clean.

• Pump impeller is partially clogged with debris causing motor to run slow and overload, remove pump and clean.

• Motor stator may be defective.

• Fuse size or circuit breaker may be too small (must be 15 amps).

• Impeller or volute opening are fully or partially clogged, remove pump and clean.

• Inlet holes in pump base are clogged, remove pump and clean the openings.

• Pump impeller is partially clogged with debris causing motor to run slow and overload, remove pump and clean.

• Motor stator may be defective.

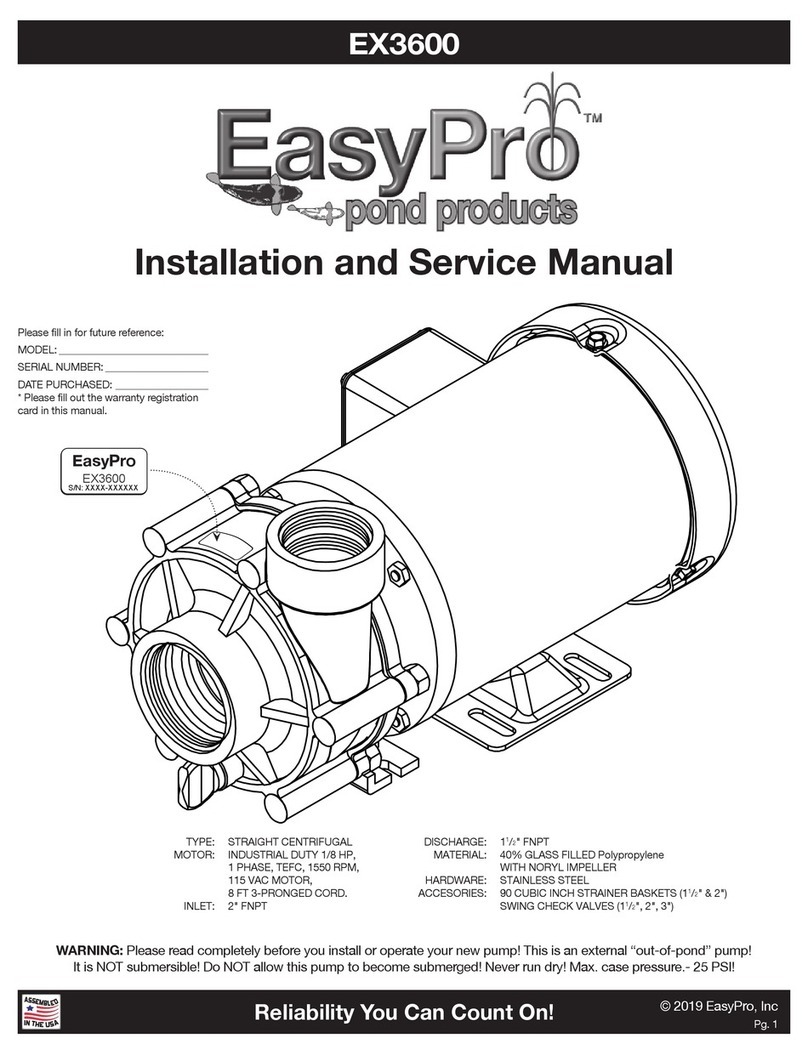

TM9500/ TM13500 TM17500

No. Description Material Q'ty

01 Motor Cap FC200 1

02 Upper Bearing Cover FC200 1

03 Motor Housing SUS304 1

04 Rotor SUS410 1

05 Stator C60 1

06 Seal Cover FC200 1

07 Oil Seal Cover FC200 1

08 Pump Casing FC200 1

09 Impeller FC200 1

SUS

(for TM9500/TM13500)

FCD45 (for TM17500)

11 Flange FC200 1

12 Upper Bearing 1

13 Lower Bearing 1

14 Mech. Seal SIC/SIC+CA/CE 1

15 Oil Seal NBR 1

16 Shaft Sleeve SUS 1

17 Handle NBR+SUS 1

18 Power Cord 1

110 Strainer