3

1

2

3

4

5

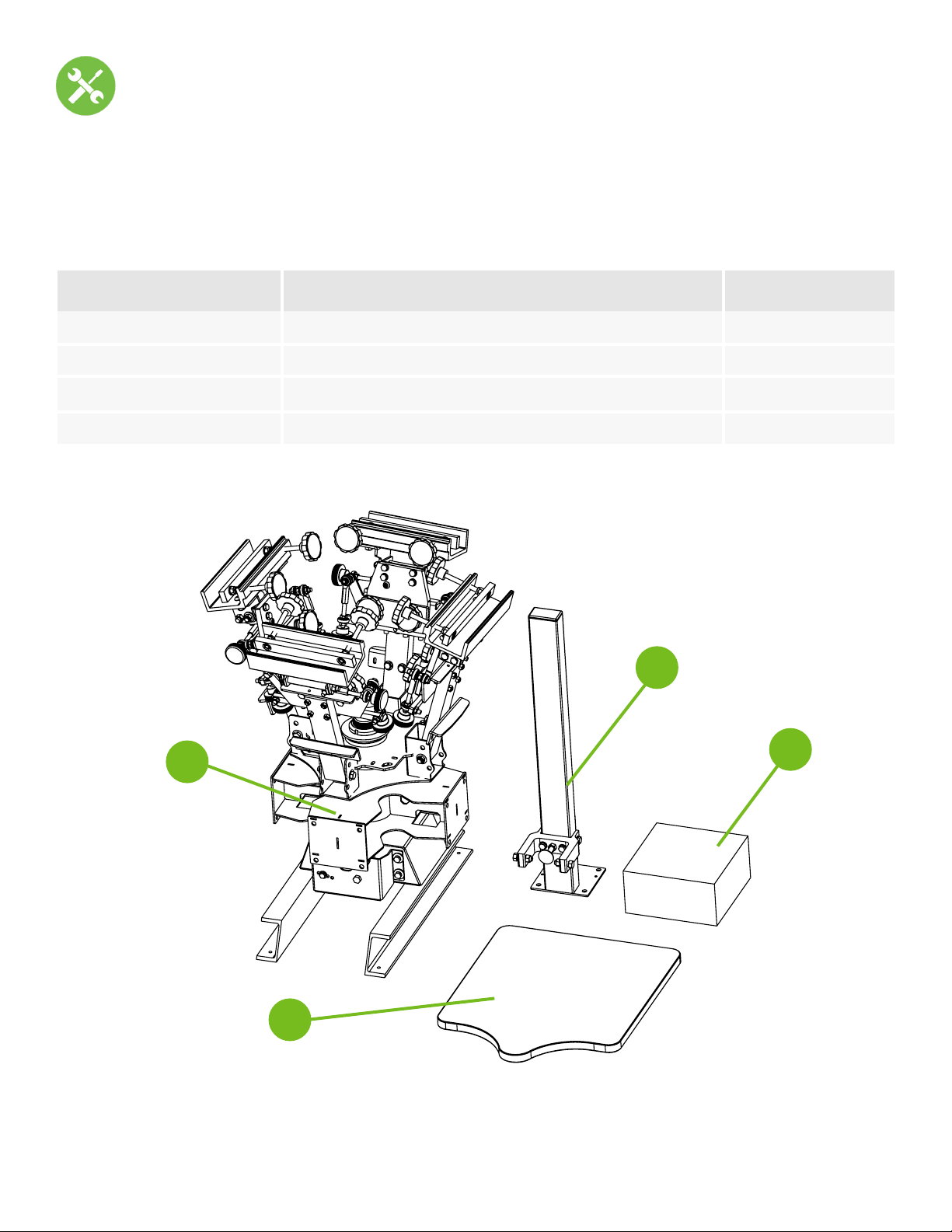

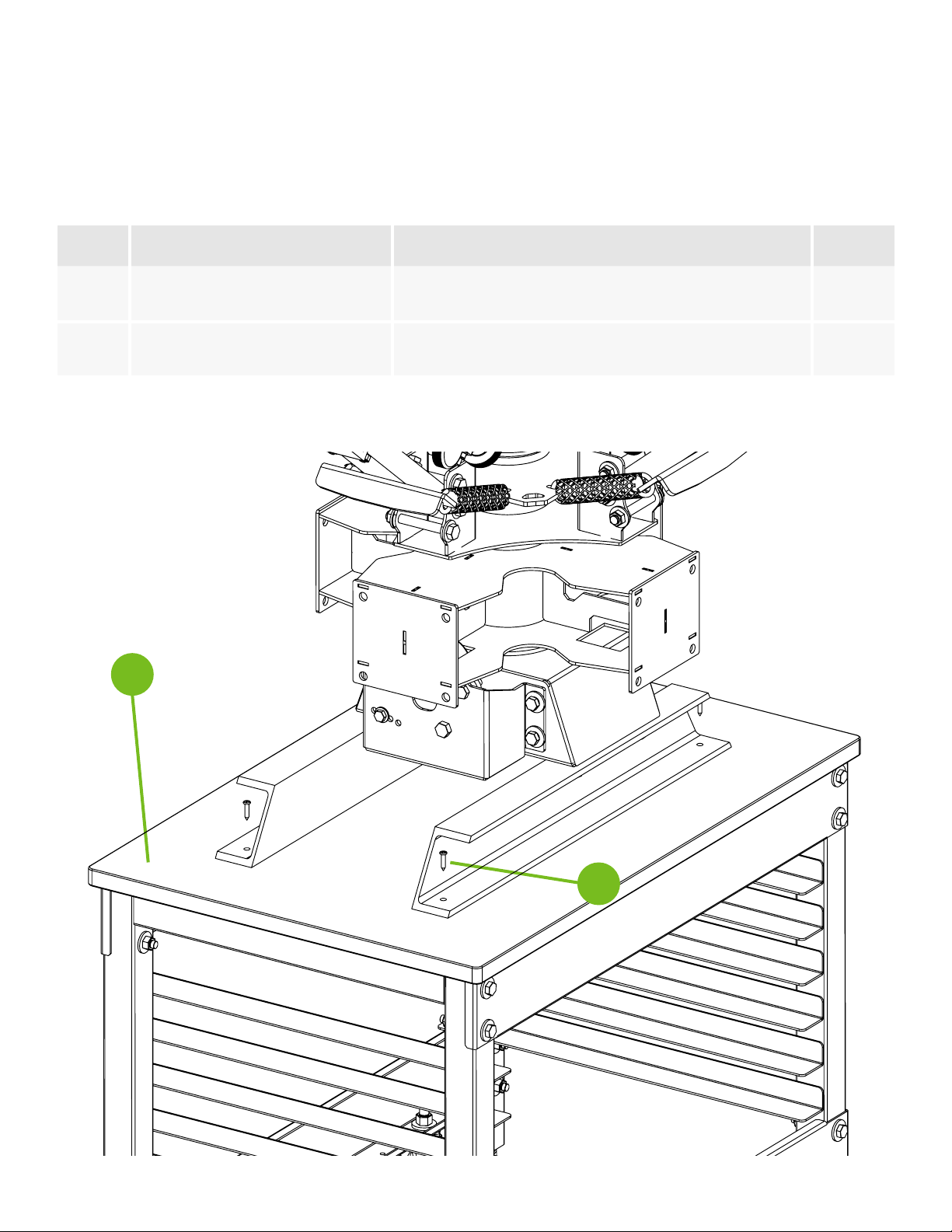

PRCO-RH250SKIT (1 kit per print station)

RILEY 250 PRINT STATION MOUNTING HARDWARE KIT

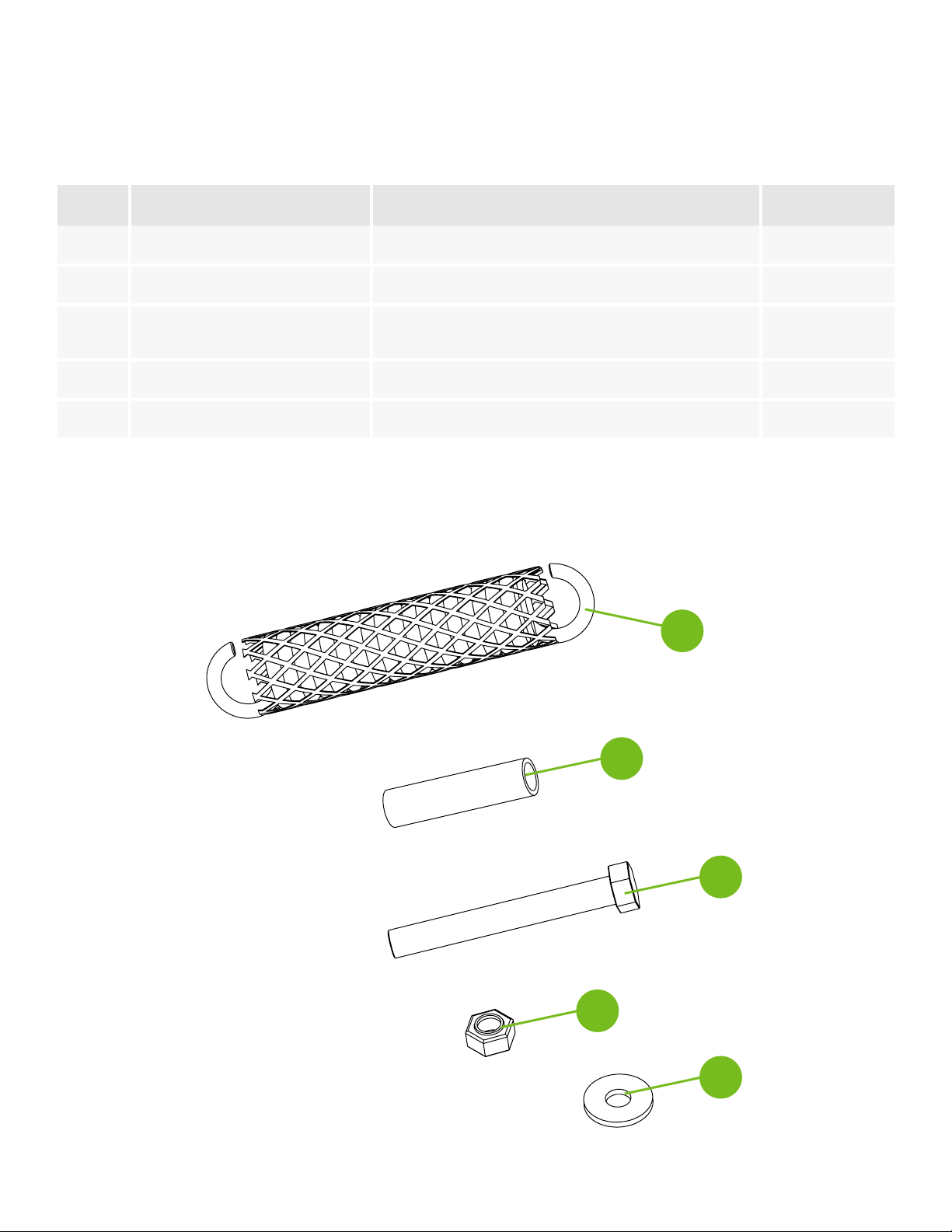

Tag NAME/ID DESCRIPTION Q.

1PRHD-HC5/16NC1GR5ZC 5/16-18 X 1 HEX TAP BOLT 4

2PRHD-WA5/16USSGR5ZC 5/16 USS FLAT WASHER ZINC 4

3PRHD-WA1/4USSGR5ZC 1/4 USS FLAT WASHER ZINC 4

4PRHD-NYN5/16NCGR5ZC 5/16-18 NYLOC NUT ZINC 4

5PRHD-RP3/16X1ZC 3/16 X 1 ROLL PIN ZINC 2