3/43

1Safety Instructions.................................................................................................................................6

1.1 Terms................................................................................................................................................. 6

1.1.1 Operation....................................................................................................................................... 6

1.1.2 Maintenance .................................................................................................................................. 6

1.1.3 Qualified Staff ................................................................................................................................ 6

1.2 Symbols............................................................................................................................................. 6

1.3 General safety information................................................................................................................. 8

2Delivery, internal transportation, unpacking.......................................................................................9

2.1 Delivery.............................................................................................................................................. 9

2.2 Internal transport................................................................................................................................ 9

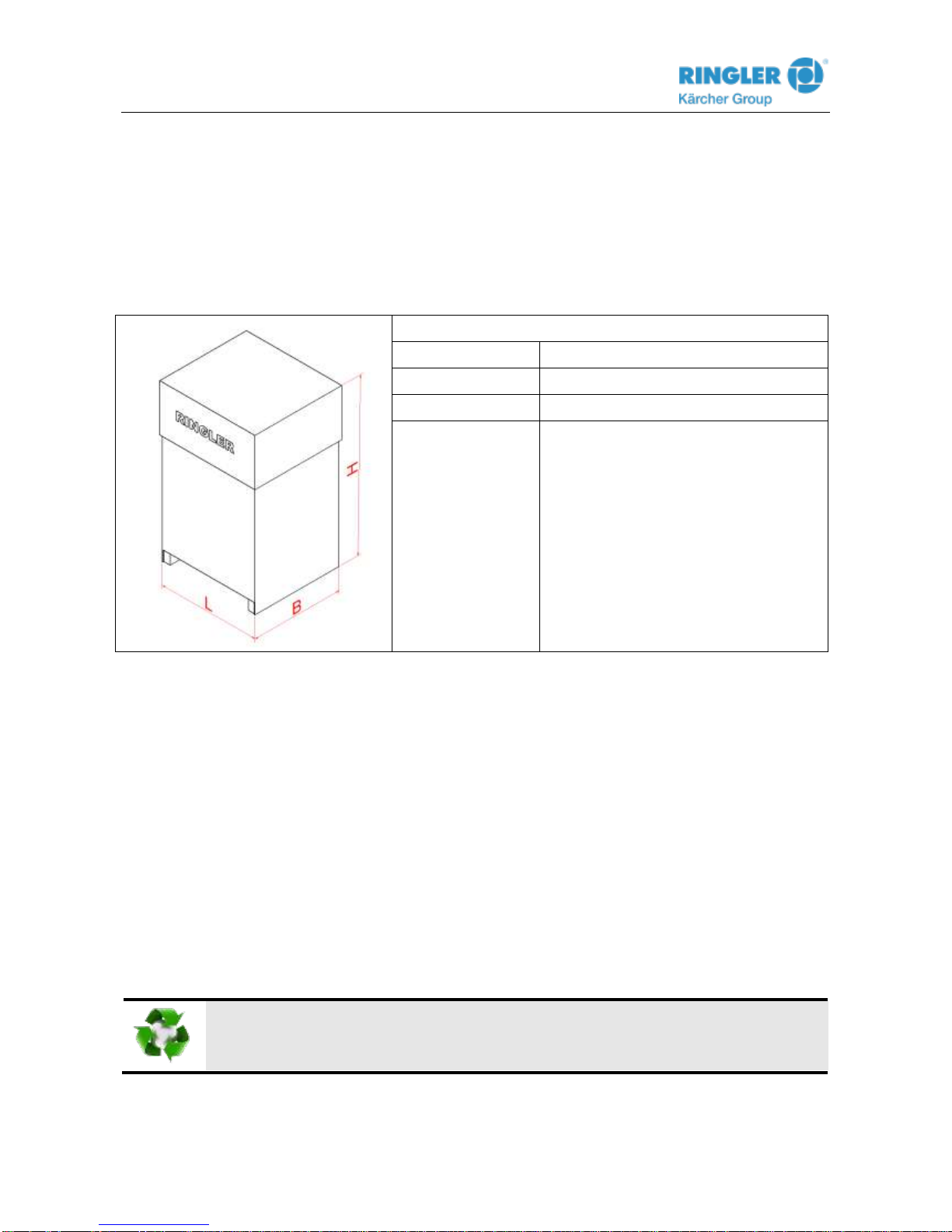

2.2.1 Dimensions and weight.................................................................................................................. 9

2.3 Unpacking.......................................................................................................................................... 9

2.4 Packaging material............................................................................................................................ 9

2.5 Storage conditions........................................................................................................................... 10

2.5.1 Information for storage................................................................................................................. 10

3Appliance description..........................................................................................................................11

3.1 Intended Use ................................................................................................................................... 11

3.1.1 Dust class "L"............................................................................................................................... 11

3.2 Non-Intended Use............................................................................................................................ 11

3.2.1 Dust class "L"............................................................................................................................... 11

4Layout and function.............................................................................................................................12

4.1 Main dimensions.............................................................................................................................. 12

4.2 Technical Data RI 080 ..................................................................................................................... 12

4.3 Technical Data................................................................................................................................. 12

5Main components.................................................................................................................................13

5.1 RI 80-W components....................................................................................................................... 13

5.2 Functional description of the chip suction plant............................................................................... 14

6Initiation.................................................................................................................................................15

6.1 Initial operation of the chip............................................................................................................... 15

7Operation...............................................................................................................................................16

7.1 Operation......................................................................................................................................... 16

7.1.1 Two-stage switch......................................................................................................................... 16

7.2 Suction process ............................................................................................................................... 16

7.3 Emptying the collecting tank............................................................................................................ 17

7.3.1 Preparations for emptying the collecting tank.............................................................................. 17

7.3.2 Manual drainage Type RI 80 ....................................................................................................... 17

7.3.3 Emptying liquids........................................................................................................................... 17

7.4 Level indicator on control pipe (ENG-003026) ................................................................................ 17

7.5 Handling notes................................................................................................................................. 18

7.5.1 Suction insert with baffle plate..................................................................................................... 18

7.5.2 Suction insert with baffle plate and perforated basket................................................................. 18

8Troubleshooting and fault elimination...............................................................................................19

8.1 Safety instructions ........................................................................................................................... 19

8.2 Initial fault elimination measures ..................................................................................................... 19

9Maintenance/Repair..............................................................................................................................20