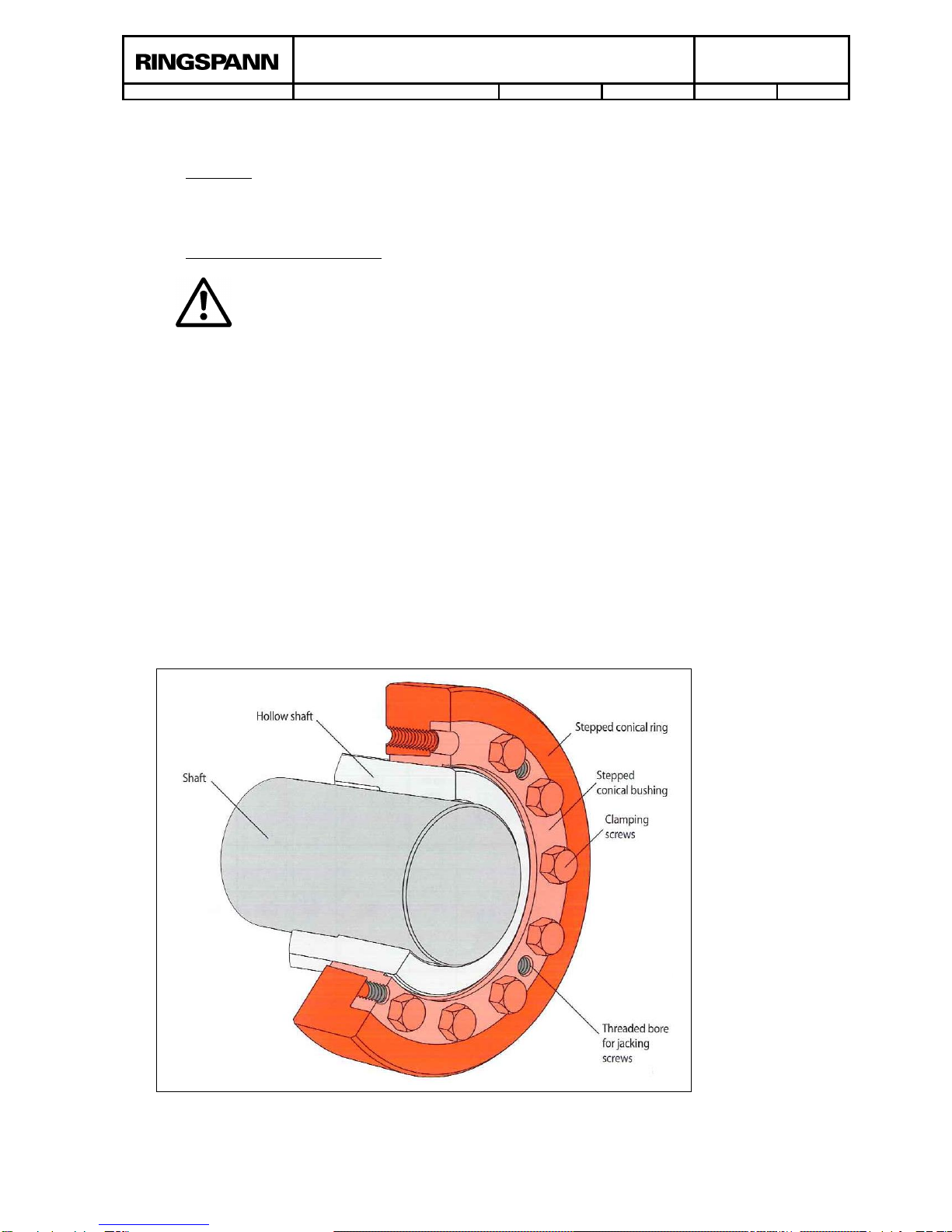

8. Installation

8.1 Clean the hollow shaft bore and the shaft thoroughly to remove all dirt, oil and grease and

ensure a friction coefficient of µ ≥ 0,15 on all contact surfaces. This surfaces are not allowed

to oil or grease.

8.2 Apply a light coat of grease to the outer diameter of the hollow shaft at the point at which the

shrink disc is positioned (picture 8.1, diameter d).

8.3 Insert the shaft into the hollow shaft.

8.4 Push the shrink disc onto the hollow shaft.

A shaft must always be inserted in the hollow shaft when mounting the shrink

disc!

8.5 Tighten the clamping crews by hand. Then tighten all screws with a suitable tool in a

clockwise sequence, turning each screw by a ¼ revolution in each step.

8.6 Continue to tighten the clamping screws uniformly in sequence by

a ¼ revolution until the stepped tapered ring and the stepped

tapered bushing are flush with the screw-side face.

Note: When installing shrink discs with slotted stepped tapered

bushing, begin with the screw to the left of the slot and

tighten the screws as described in Section 8.6.

Installation is distance-controlled. Therefore, it is not

necessary to use a torque wrench!

Replace missing or damaged clamping screws with

equivalent screws of quality grade 12.9 only, grease new

screws like described under 10.2!

9. Disassembly

9.1 Loosen the clamping screws uniformly in multiple steps by ¼ revolution for each step to

prevent misalignment of the clamping surfaces and breaking of screws.

Do not remove clamping screws completely from threaded bores under any

circumstances, as this poses the risk of injury.

9.2 Do not separate the two rings directly. Instead, remove as many clamping screws as

threaded press-off bores in the stepped tapered bushing and turn them into the press-off

bores uniformly until the stepped tapered ring is pressed free of the stepped tapered

bushing.

9.3 Remove the shrink disc from the hollow shaft.