6

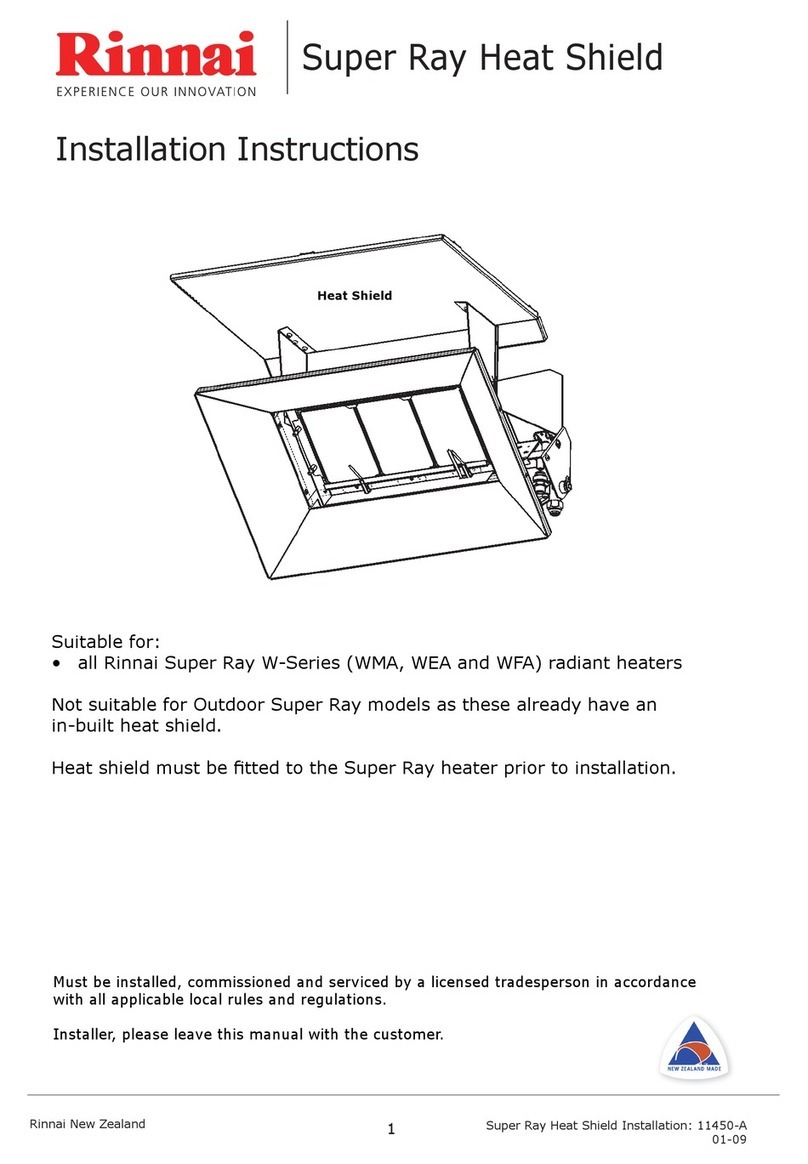

Diagram shows

minimum

clearances from

combustible

materials

15 LPG containers must not be installed

indoors.

16 Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect

the room heater and to replace any part

of the control system and any gas control

which has been under water.

17 Adequate clearances for accessibility for

purposes of servicing and proper

operation should be provided.

18 Adequate clearances around air

openings into the combustion chamber

should be provided.

19 Do not install in areas where curtains,

drapes, clothing, or other moving

flammables are within 15 inches of this

unit.

The appliance must be isolated from the

gas supply piping system by closing its

equipment shutoff valve during any

pressure testing of the gas supply piping

system at pressures equal to or less than

½ psi (3.5 kPa).

24 The draft hood on the appliance should

be installed in the same atmospheric

pressure zone as the combustion air inlet

to the appliance and shall be located so

that the relief opening is accessible for

checking vent operation.

25 The appliance, when installed, must be

electrically grounded in accordance with

local codes or, in the absence of local

codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.1

26 A gas appliance must not be connected

to a chimney flue serving a solid fuel

burning appliance.

27 Do not restrict the warm air discharge

by placing articles in front of heater.

28 This appliance must not be used for any

purpose other than heating.

29 Do not allow anyone to post articles

through the louvres.

30 Do not allow anyone to sit or lean

against the appliance.

31 DUE TO HIGH TEMPERATURES, THE

APPLIANCE SHOULD BE LOCATED

OUT OF TRAFFIC AND AWAY FROM

FURNITURE AND DRAPERIES.

32 CHILDREN AND ADULTS SHOULD BE

ALERTED TO THE HAZARDS OF

HIGH SURFACE TEMPERATURES

AND SHOULD STAY AWAY TO AVOID

BURNS OR CLOTHING IGNITION.

33 CLOTHING OR OTHER FLAMMABLE

MATERIAL SHOULD NOT BE PLACED

ON OR NEAR THE APPLIANCE.

34 INSTALLATION AND REPAIR SHOULD

BE DONE BY A QUALIFIED SERVICE

PERSON. THE APPLIANCE SHOULD

BE INSPECTED BEFORE USE AND

20 Periodic examination of the venting

system is required.

21 The flow of combustion and ventilation

air should not be obstructed.

22 A manufactured home (USA only) or

mobile home OEM installation must

conform with the Manufactured Home

Construction and Safety Standard,

Title 24CFR, Part 3280, or, when such

a standard is not applicable, the

Standard for Manufactured Home

Installations, ANSI/NCSBCS A225.1 or

Standard for Gas Equipped

Recreational Vehicles and Mobile

Housing, CSA Z240.4.

23 The appliance and its appliance main

gas valve must be disconnected from the

gas supply piping system during any

pressure testing of that system at test

pressures in excess of 1/2 psi (3.5 kPa).

15”

ABOVE

15”

RIGHT

15”

LEFT

15”

FRONT