Rinnai 3 DD FP Solar Pre Heat System OIM

TABLE OF CONTENTS

Warnings and Important Information 4

Safety and Regulatory Information ........................................................................................................................................ 4

Scald Hazards ....................................................................................................................................................................... 5

Safety Devices ....................................................................................................................................................................... 6

Hydrogen Gas ........................................................................................................................................................................ 7

Water Temperature ................................................................................................................................................................ 7

Water Quality ......................................................................................................................................................................... 7

Draining and Filling the Water Heating System ..................................................................................................................... 7

Maintenance and Regular Care ............................................................................................................................................. 7

Servicing and Repair ............................................................................................................................................................. 7

Installation 8

Regulations and Occupation Health and Safety (OH&S) ..................................................................................................... 8

Location - General Information .............................................................................................................................................. 8

Hi Rise Kits in Conjunction with Split System Flat Roof Frames ........................................................................................... 8

Water Pipes and Supply ........................................................................................................................................................ 8

Hot Water Delivery Temperature ............................................................................................................................................ 9

Storage Cylinder Location ..................................................................................................................................................... 9

Valves and Fittings ................................................................................................................................................................. 9

Installation Procedure .......................................................................................................................................................... 10

Installation - Solar Collectors 12

Regulations and Occupation Health and Safety (OH&S) ................................................................................................... 12

Solar Collector Specications .............................................................................................................................................. 12

System Orientation and Inclination ...................................................................................................................................... 13

Pipe and Pump Sizing ......................................................................................................................................................... 13

Components ........................................................................................................................................................................ 14

Collector Mounting Rail Pre Assembly ................................................................................................................................. 15

Installation on a Pitched Tile Roof ....................................................................................................................................... 16

Installation on a Pitched Metal Roof .................................................................................................................................... 17

Installation on a Flat Roof Frame ......................................................................................................................................... 18

Collector Spacing Requirements ......................................................................................................................................... 19

Flow and Return Line Layout ............................................................................................................................................... 20

Collector Fitting Details ........................................................................................................................................................ 20

Storage Cylinders 22

Specications ....................................................................................................................................................................... 22

Components Supplied With Cylinders ................................................................................................................................. 22

Dimensions ......................................................................................................................................................................... 23

Pump and Controller 25

Components Supplied in Solar Controller Kits ..................................................................................................................... 25

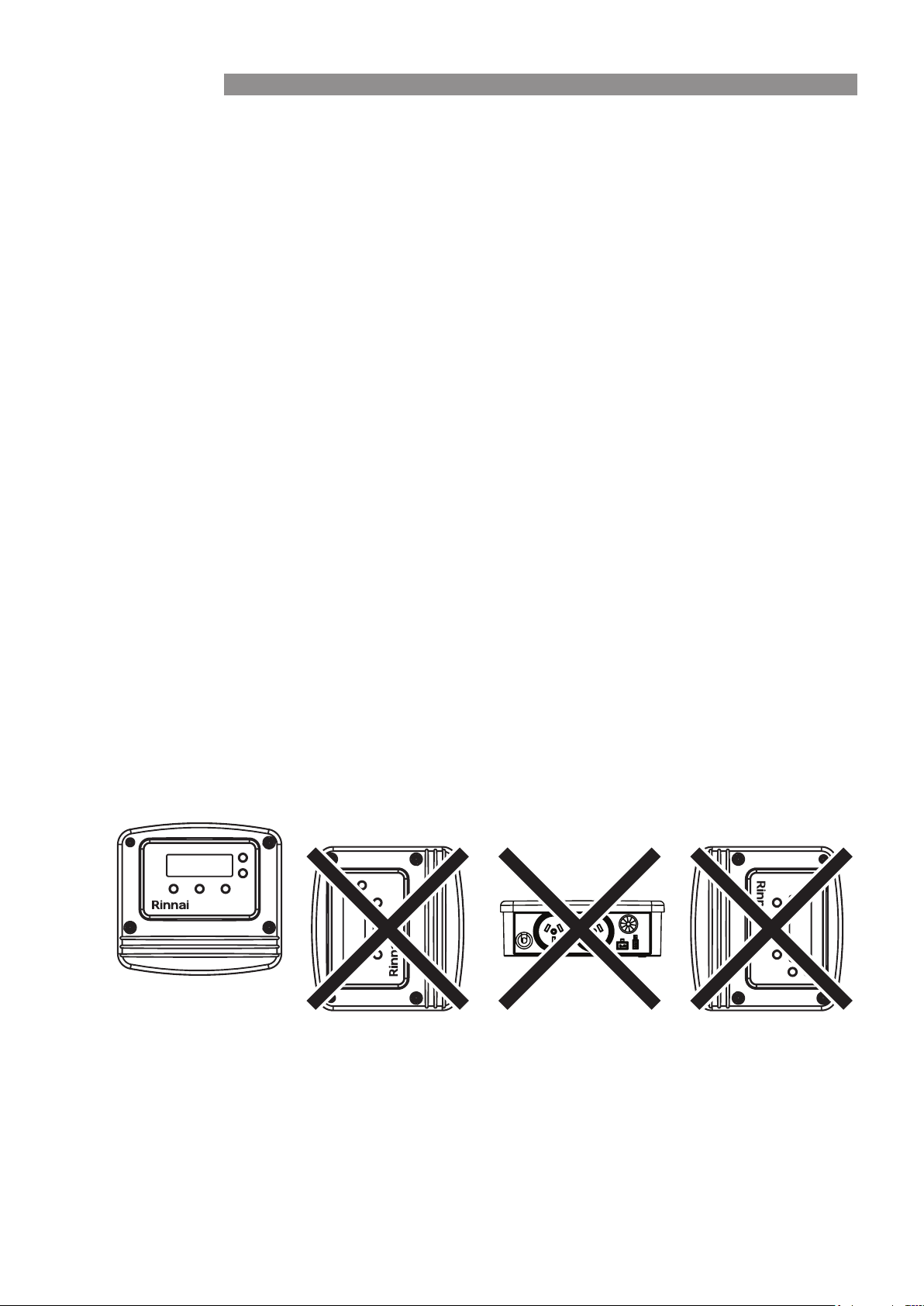

Solar Controller .................................................................................................................................................................... 26

Gas Boosting 27

Solar Preheat with Manifold Pack ........................................................................................................................................ 27

Solar Preheat With Demand Duo ........................................................................................................................................ 28

Solar Preheat with Demand Duo and Warm Water Valve ................................................................................................... 29

Save a Service Call 30

Contacts 32