5

Override

Temporarily changes operation from ON to

OFF or OFF to ON until the next programmed

setting is reached.

Timer 1 and Timer 2

Displays which timer is operating.

Lock

Locks all controls when pressed except OFF.

Hold for two seconds to deactivate. If the lock is

pressed while the heater is o all functions will

be locked, including turning the heater on, until

it is deactivated.

Filter

Indicates the lter needs cleaning. If you do

not clean the lter at regular intervals and the

lter indicator is allowed to remain ashing, the

appliance will stop and the display will show

error code 14. The lter will need cleaning

before the appliance can be turned back on.

Clock and timer indicators

When programming, the indicators will glow to

indicate what is being programmed. The ‘Temp’

indicator indicates the set temperature for the

timer that is being set.

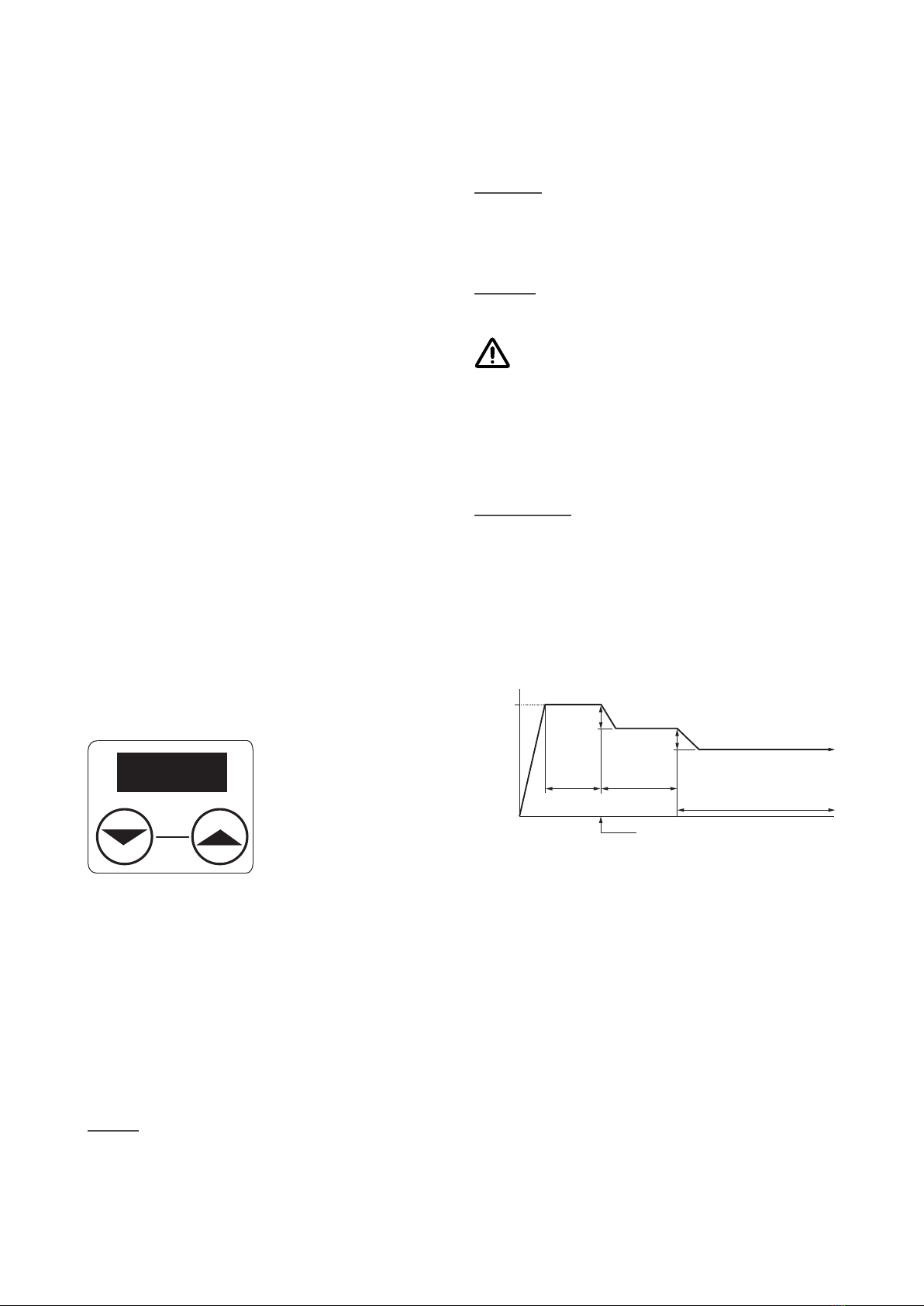

Display window

Shows either the time of day, temperature or

error code.

Adjusting the room temperature

Pressing the up and down arrows will

change the preset temperature by 1 °C. The

temperature will be shown in the display

window. The room temperature sensor is

located behind the Energysaver so the

temperature on the display may vary slightly

from the actual room temperature.

The temperature can be set to:

L (low)

Typically used to keep the chill o a large room.

The unit operates on the lowest burner setting. If

the room temperature is above 10 °C, the burner

will switch o, the fan will wind down, and the

appliance will stop heating. If the temperature

then drops below 10 °C the heater will switch

back on.

16-26 °C

Unit will modulate, and in some instances

turn o and on, to maintain the selected

temperature.

H (high)

Unit operates on the highest burner setting.

The ‘L’ and ‘H’ settings are not normally

used as this means the heater operates

without a set temperature.

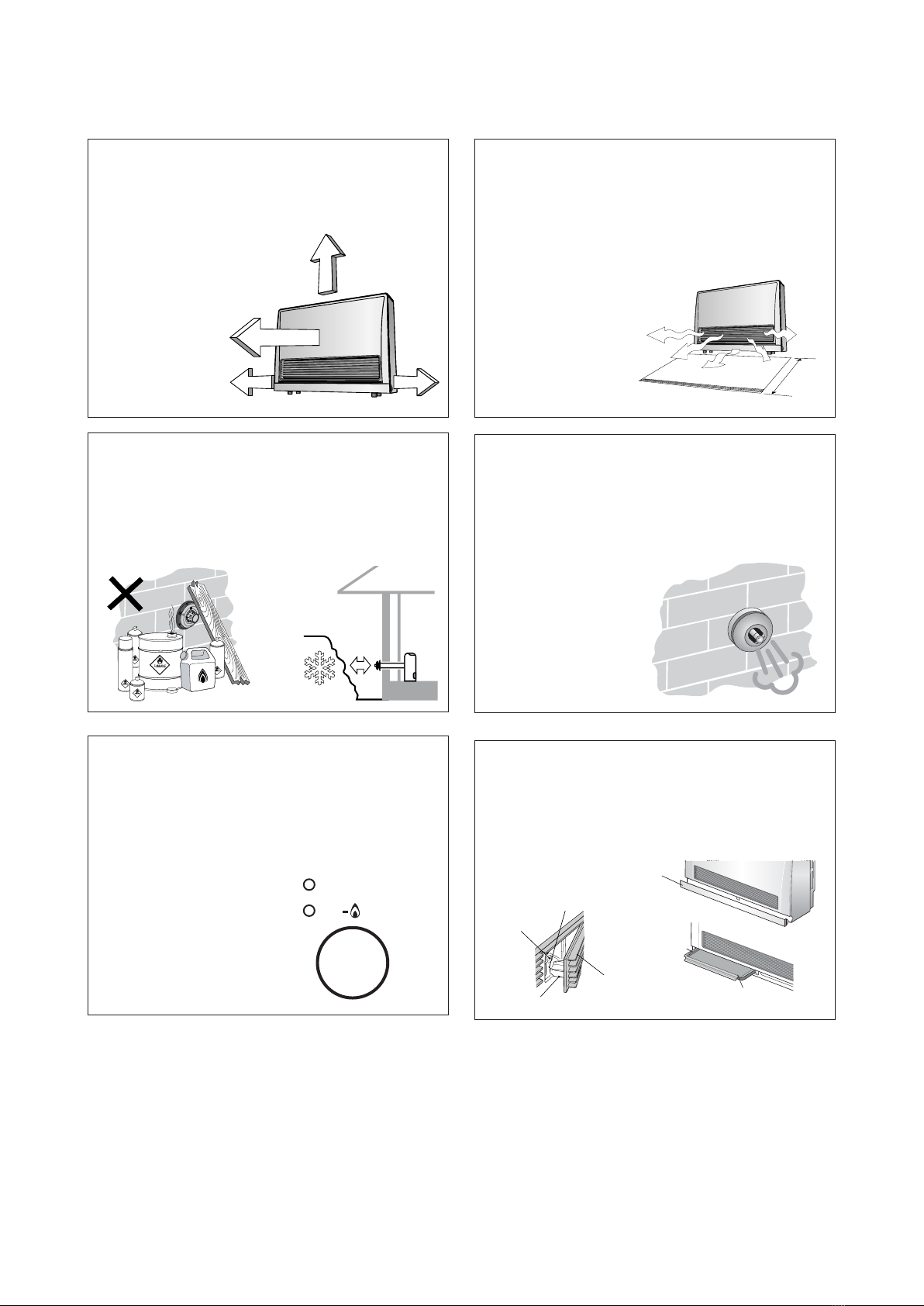

Economy

Prevents the room overheating and reduces

gas consumption.

How it works

After the room reaches the set temperature,

the set temperature will automatically start

decreasing, dropping by a maximum of 1 °C

in 30 minute blocks, until ‘comfort control’ is

reached. When in comfort control the unit alters

combustion and fan speed to keep the room at

a comfortable temperature.

2 1 2 1

AM

PM

Set Room

Temp

Time

NOTE

Set

room

temp. Max. 1 °C

Max. 1 °C

Total 2 °C Comfort control

Economy indicator illuminates