www.neutec.com About Your J-2rPage 1-1

Section One: About Your J-2r

Introduction

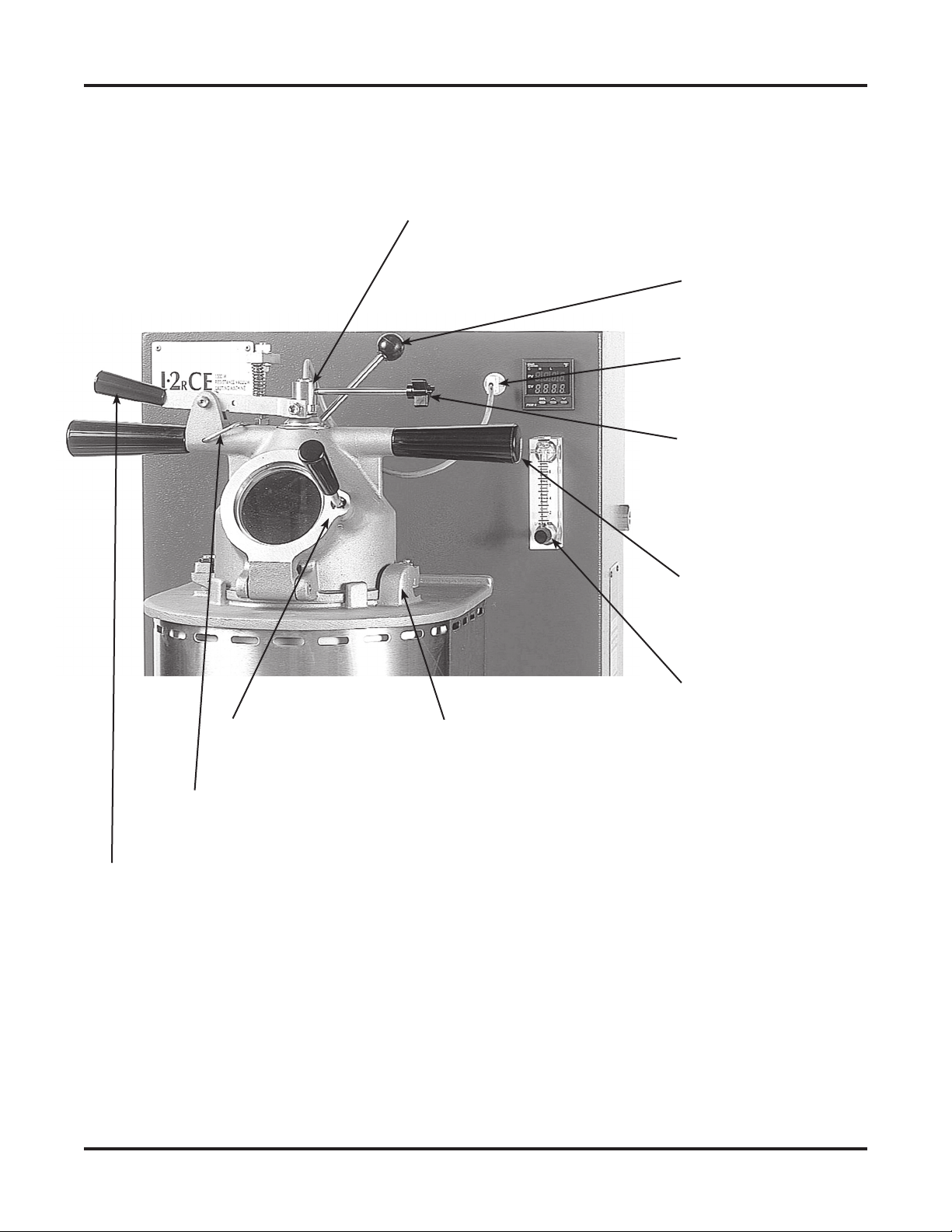

The J-2rfrom Neutec/Rio Grande™ incorporates

many of the important casting features found in

the Neutec™systematic approach to casting. It is

resistance-heated, meaning that it uses a

low-voltage electric coil to heat the melting

crucible, and has a sophisticated temperature

controller. The J-2r is an excellent choice for the

craftsman/designer working out of a small shop

where high production levels are not a daily

necessity. Cost/benefit ratios make it possible to

own a J-2reven when one-of-a-kind casting is

the majority of your workflow. The J-2rincludes:

• Accurate temperature control.

• PID fuzzy logic controllers

• Protective inert-gas (nitrogen or argon)

atmosphere prevents oxidation.

• Bottom-pour crucible preserves metal

temperature during the pour and leaves any

slag or other contaminants in the button,

not in your casting.

• Closed-system stirring of alloys maintains

the protective atmosphere in the crucible.

• Low-voltage coil prevents electrical shock

and provides a long service life.

After initial heat up, casting cycles average

about 8 minutes, depending on metal type and

load size. The entire cycle assumes an attentive

operator reading the display and taking the

appropriate actions at the appropriate times.

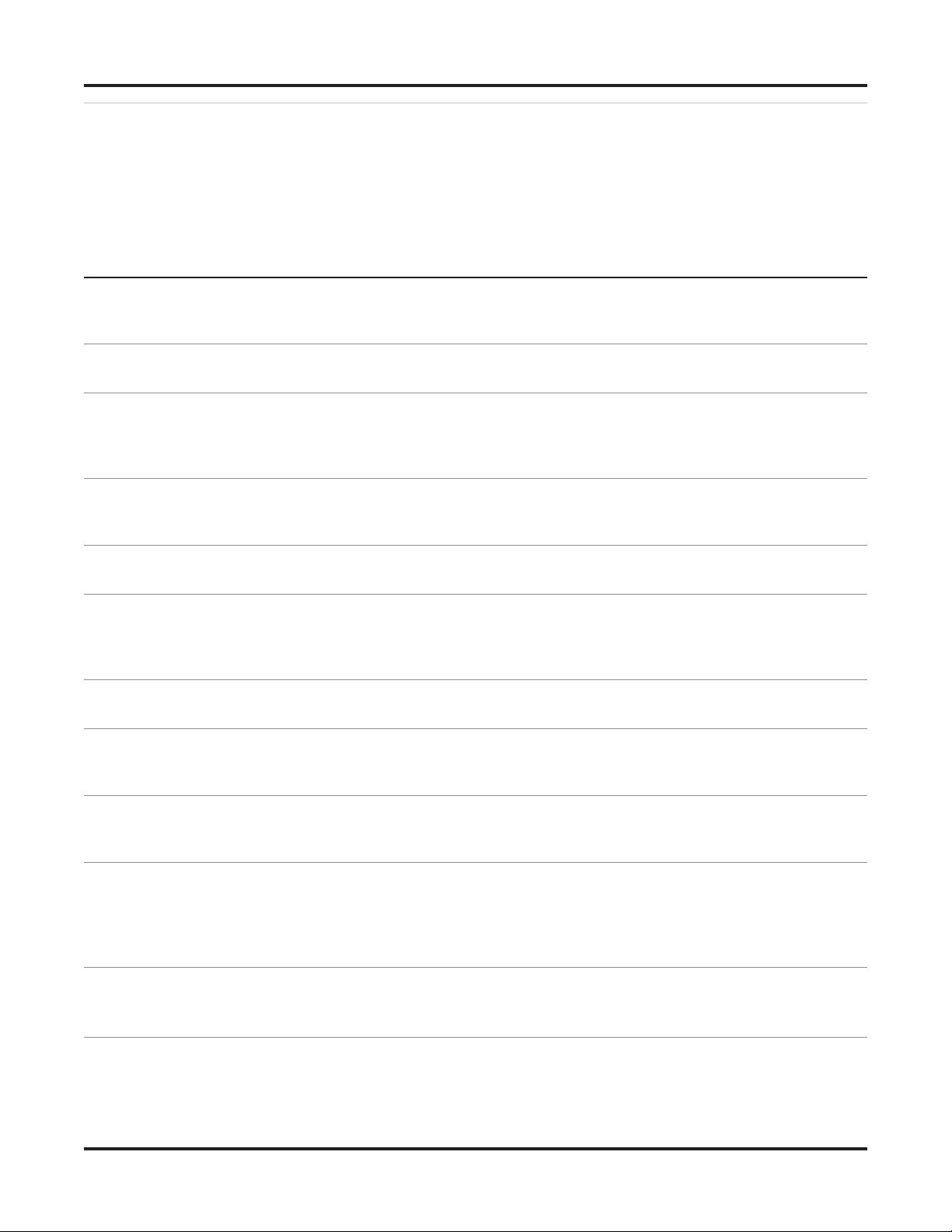

Crucible Capacity: The maximum working

capacities of the J-2rare shown in the following

chart. Working capacity (the amount of casting

grain the crucible can hold before melting) is

approximately 60% of the crucible liquid

capacity. The working capacity varies depending

on the size and shape of your casting grain.

Metal Working Capacity

(grams) (dwt)

24KY 1,300 850

18KY 1,050 650

14KY 900 550

10KY 750 500

Sterling 700 450

J-2r crucible working capacity

Melting Time: For an initial cycle, starting

with a cool crucible, heating time is about 40

minutes; subsequent casting cycles range from

6–8 minutes depending on the size of the load.

Maximum Flask Size:

102mm diameter x 229mm H (4" dia. x 9"H).

Power Requirements: 208–240 volts, single-

phase, 1.5kW; requires a 15-amp circuit with

a circuit breaker.

Inert Gas Requirements: Nitrogen or argon;

8 lpm minimum at 0.7 bar (10 psi).

Important! Gas must be pure and

contain no oxygen or any combustible gas.

Dimensions: 46cmW x 46cmD x 76cmH

(18"W x 18"D x 311/2"H).

Weight: 54kg (119 lbs.);

shipping weight: 60kg (132 lbs.).

Vacuum Requirements: one external 5cfm

vacuum pump.