Rioned Andy Guest Jetters 2 Series User manual

1

2-SERIES OPERATOR’S MANUAL

OPERATOR’S MANUAL

HIGH-PRESSURE JETTING MACHINE

2-SERIES

WWW.ANDYGUESTJETTERS.CO.UK

© Copyright June 2022, Andy Guest Jetters Ltd

Unit 11, Riparian Way

The Crossings Business Park

Cross Hills

Keighley

West Yorkshire, UK

BD20 7BW

Tel: +44 (0)3300 240404

Fax: +44 (0)1535 636969

Web: www.andyguestjetters.co.uk

All rights reserved. No part of this publication may be copied or published by means of printing, photocopying,

microfilm or otherwise without the prior written consent of Andy Guest Jetters Ltd.

This restriction also serves in respect of all corresponding drawings and diagrams.

Andy Guest Jetters Ltd has the right to change components and assemblies at any time without prior or direct

correspondence with the operators. The contents of this manual may be changed without any prior warning.

This manual is to be used only for the equipment models stated.

For additional technical information or support please contact your local service agent which may be located on the

Company’s website.

TABLE OF CONTENTS

1.0 INTRODUCTION 4

2.0 FUNCTIONALITY & GENERAL SAFETY 5

2.1 Equipment methodology 5

2.2 Installation 6

2.3 Safety Icons 6

2.4 Critical Safety Features 6

2.5 Personnel Protection Equipment (PPE) 6

2.6 General Warnings 7

2.7 Making Changes and Fabricating Non OEM Components 7

2.8 Machine Warranty 7

3.0 TECHNICAL SPECIFICATIONS 8

4.0 CONSTRUCTION 9

5.0 CONTROLS 11

5.1 Before Departure 11

5.2 Positioning the Vehicle 11

5.3 Hydraulic Reel Control 11

5.4 Engine Counter 11

5.5 Run Dry Protection (Optional) 11

5.6 Pre-Operational Checks 11

5.7 Starting the Engine 12

5.8 Stopping the Engine 12

5.9 Completion Procedures 12

5.10 Operating the machine 12

5.11 Using the Radio Remote Control (Optional) 13

5.12 Nozzle Application 12

5.13 Using Lances 12

5.14 Frost Protection 14

5.15 Recommended Maintenance Schedules 15

6.0 TROUBLESHOOTING 16

6.1 Troubleshooting Guide 16

6.2 Useful Links & External References 17

7.0 SERVICE CENTRES 18

7.1 Manufacturing Sales + Service 18

7.2 Service Agents 18

8.0 APPENDIX 19

8.1 Declarations & Directives 19

42-SERIES OPERATOR’S MANUAL

Andy Guest Jetters Ltd wishes to first thank you for

your purchase of our drain and sewer-clearing

equipment. We recommend that you read this

manual thoroughly to ensure that the equipment is

maintained and operated to the highest standard.

If you require technical support, additional parts or

services or indeed would like to schedule an

approved service – please don’t hesitate in

contacting us.

The machine is built by:

Andy Guest Jetters Ltd

Unit 11, Riparian Way

The Crossings Business Park

Cross Hills

Keighley

West Yorkshire, UK

BD20 7BW

The equipment has been specifically designed and

manufactured for cleaning and unblocking

domestic and commercial drains in conjunction

with the uniquely calibrated high pressure jetting

nozzles that are supplied with your equipment (other

specialist nozzles are available for pipe cleaning,

silt removal, high fat content, other foreign material

based blockages and root cutting).

Other common uses for the equipment include the

cleaning and maintenance of walls, floors, building

materials and rubbish containers with cold or warm

water and can be used with our collection of lances

and accessories. If you aren’t sure about a particular

application you should always contact us in the first

instance for advice as no liability can be placed on

the company for consequential damage, theft or

injury to persons or property.

This manual contains all the necessary information

concerning control and maintenance. If the device is

installed correctly, properly controlled and regularly

maintained then the owner may invoke a warranty

claim for non-wear parts subject to the terms of sale

(which is normally 12 months from date of invoice

for new equipment and 3 months on second hand

purchases). Should, following our investigation it be

determined that the control and maintenance

procedures are not diligently followed, the

warranty will become invalid – this does not aect

your statutory rights.

The machine may only be used by authorised

personnel and should not be operated in an

explosive or hazardous environment. In this

manual you will find necessary information about the

operation and maintenance of your machine.

1.0 INTRODUCTION

Foreword

This operator’s manual is designed for trained and competent users of industrial jetting

equipment as prescribed by the Water Jetting Association of the United

Kingdom. The purpose of the manual is to ensure safe and ecient operation of

the equipment with any associated drawings or images to serve as a guide only.

In each section we try to familiarise users with the most important safety aspects to

consider prior to the operation of the equipment along with the operating controls and

diagnosis of potential faults.

5

2-SERIES OPERATOR’S MANUAL

2.1 Equipment Methodology

The integrated engine drives the high-pressure

pump via a gearbox system or drive belt. This pump

receives water from the water tank (which is usually

filled via the inlet reel), via the water filter before

pressurisation is applied to the desired level.

The pressurised water is ejected through the

high-pressure hose (black in colour and mounted

on the HP reel) and eventually passes through the

high-pressure jetting nozzle.

A three metre “leader hose”, normally blue in colour,

is supplied as standard with all new equipment.

When retracting a hose that is in operation, this tells

the operator that they are nearing the end of the line

and so the pump should be turned o to reduce the

risk of high pressure water being on operation

outside of the confines of the application, for

example the sewer pipe. High pressure water and

an “out of control” nozzle present one of the highest

risks to health and property when this equipment is

in use.

Most machines are derived by the type and

power of the engine – normally between

20-55 horsepower (HP).

Typically the size of engine will determine the size of

pump however these can be varied in accordance

with the two principal factors of jetter specification

– pressure (velocity of water) and flow (volume of

water). These are normally quoted in PSI (pounds per

square inch) or BAR (derived from the Greek word

baros meaning weight with 1 bar being equal to

atmospheric pressure) and Gallons or Litres per

minute – for example 3000@12 refers to 3000psi at

12 gpm and is considered one of the most common

specifications to deal with the largest volume of drain

blockages in the most ecient manner.

⊲ 1 bar is equal to 14.5 psi

⊲ 1 UK gallon is equal to 4.55 litres

There are many types of engines and pumps and

many arrangements of equipment resulting in

dierent weights, sizes, serviceability and

performance. Our equipment has been developed

over time to provide a configuration that we

believe oers a high level of performance, safety

and reliability with low ownership costs.

Whilst the financial measure of the life of our

equipment tends to be governed by customer

accounting policies, the practical life of the

machine if properly maintained can be up to 20

years depending on usage. There is a market for

used machines for which our brand of equipment

is still very desirable and as such we would always

recommend having second hand equipment that

hasn’t been refurbished by the OEM (original

equipment manufacturer) or a recognised service

agent – to be multi-point checked prior to operation.

Other common accessories for safety and

eciency include wireless remote control handset

and receiver units to turn the water on and o when

operating the jetter at a distance from the vehicle.

Remote units have the facility to start/stop water,

start/stop engine, retract the high-pressure hose reel

or provide emergency stop capabilities, depending

on the number of channels purchased and installed.

2.0 FUNCTIONALITY & GENERAL SAFETY

62-SERIES OPERATOR’S MANUAL

2.0 FUNCTIONALITY & GENERAL SAFETY

For additional protection of people or equipment,

unloader valves and run-dry switched are included

as standard on all new equipment. Unloader valves

return pressurised water back to the tank, unlike the

standard burst disc arrangement. Run dry switches

automatically stop pump operation if the machine

runs out of water.

There are also numerous optional accessories to

aid operations and safety, such as safety lances that

prevent a build-up of back pressure to the machine,

and hose guidance adapter so that operators don’t

have to come into contact with the high-pressure

hose when retracting from a sewer line.

As well as the general information in this chapter, you

should also follow the safety guidance in the other

chapters.

Always consider the safety of yourself and others

when operating this machine. Complete risk

assessments before each job to highlight potential

hazards and either avoid and/or protect people and

equipment from their consequences.

2.2 Installation

We recommend that all new machines are installed

by AG approved agents and technical teams. Third

party installation should be undertaken as per the

guidelines issued by the AG Technical Team. No

responsibility is taken for third-party installations.

2.3 Safety Icons

Any safety warnings in this manual that are

accompanied by the safety icon below (Security sign

DIN 4844-W9) are considered to present a high level

of danger to persons or equipment and should be

followed at all times.

DIN 4844-W9

2.4 Critical Safety Features

Emergency Stop

This machine is equipped with an emergency stop.

By operating the emergency stop, the machine will

stop immediately. Do not use this button for normal

operation and only use it in emergencies. The stop

button will remain depressed after application so that

the equipment cannot be restarted.

If used, and only when the danger has been

averted, twist/pull the emergency stop button back

out in order to be able to use the equipment again.

Ensure the emergency stop is always accessible.

Security Covers

This machine is equipped with several safety

covers designed to protect users from rotating parts

or hot surfaces. Do not remove these

security covers.

2.5 Personnel protection

equipment (PPE)

The following PPE is prescribed when operating the

equipment:

⊲ Ear protection (LWA 89dB)

⊲ Eye protection

⊲ Hand Protection (gloves)

⊲ Waterproof clothing

⊲ Spray boots with toe protection

Always apply PPE prior to operation of the

equipment and use your risk assessments to deter-

mine if additional PPE is required.

7

2-SERIES OPERATOR’S MANUAL

2.6 General Warnings

From our experience of commonly reported

incidents and near misses, please take note of

the following:

⊲ Never operate the equipment near a person

or animal

⊲ Use protective barriers to reduce the risk of

unauthorised access to the work area

⊲ Never block the control levers in any way or

lean equipment on or near them

⊲ Ensure that the high pressure nozzle does not

leave the drain whilst the unit is in operation

⊲ Before using a spray gun, you must always set

the pressure below the maximum (± the half of

the maximum pressure is recommended) and

this should be done before the machine

is started

⊲ Never exceed the maximum pressure that is

marked on the manometer when using the

spray gun

⊲ After use of the high-pressure circuit ensure

that you depressurise it

⊲ Always check for electrical feeds or equipment

if you are cleaning with a spray gun

⊲ Always check for loose items near the

application of the spray gun to avoid them

becoming projectiles

⊲ Personnel that use, maintain and inspect the

equipment should be suitably qualified and

authorised.

⊲ Operating the machine for sewer cleaning

means you may be exposed to bacteria and

sewer gases. Protection against contamination

is the responsibility of the operator.

⊲ Carbon Monoxide can cause severe nausea,

fainting or death. Avoid inhaling exhaust fumes.

Engine exhaust gases contain poisonous

carbon monoxide. Carbon monoxide is odour-

less, colourless, and can cause death if inhaled.

Always operate the jetting machine with the

rear doors of the van open.

⊲ Do not crank engine continuously for more

than 10 seconds. Allow a 60 second cool down

period between starting attempts. Failure to

follow these guidelines can burn out starter

motor.

⊲ If starter is engaged while flywheel is rotating,

starter pinion and flywheel ring gear may clash

resulting in damage to starter.

If the safety guidance is not observed you increase

the risk of near-misses and serious accidents.

Always try to recognise the important functions

and controls, ensure you follow maintenance and

pre-check recommendations and most importantly

remember that no job is worth risking the safety of

yourself and others.

2.7 Making Changes

and Fabricating Non

OEM Components

Changes to the machine will aect your warranty and

may result in significant rectification costs or potential

safety hazards and therefore should only be con-

ducted if authorised in writing and in advance by an

authorised representative of Andy Guest Jetters Ltd.

2.8 Machine Warranty

If the machine is set up and operated correctly and

regularly maintained, you will be covered by the

terms described in the warranty document.

If the operating and maintenance instructions are

not followed correctly, the warranty may be deemed

void and your safety and that of people in the vicinity

cannot be guaranteed.

82-SERIES OPERATOR’S MANUAL

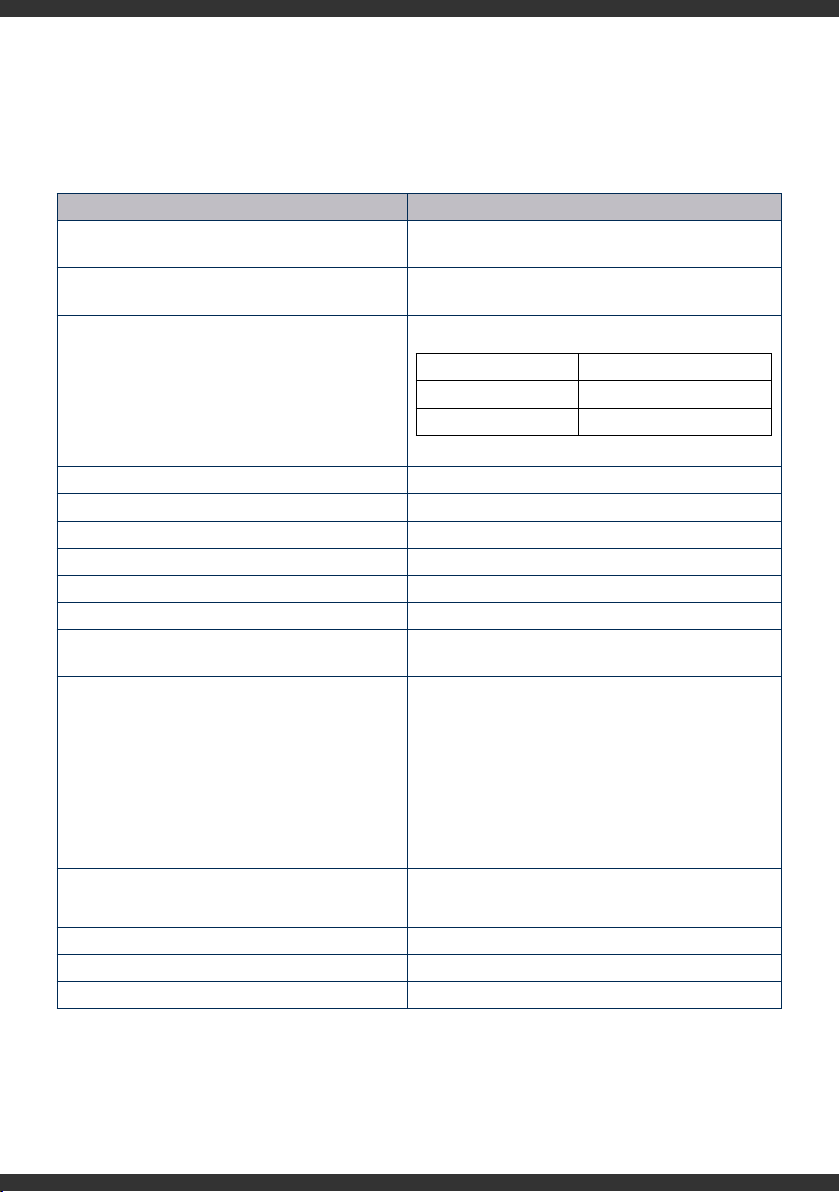

3.0 TECHNICAL SPECIFICATION

2-SERIES

www.andyguestjetters.co.uk

+44 (0)3300 240404

MADE IN UK

SERIAL No.

00-00-P000

3.1 TYPE PLATE

Every Andy Guest machines is supplied

with a Type Plate and unique serial

number, which is located in a prominent

position on the machine. When seeking

assistance with your equipment, quoting

the serial number will help us quickly

retrieve important information.

Pipework Diameter < 250mm

Performance 3000PSI @ 9GPM (200BAR @ 40LPM)

StdWater Tank Capacity 400 Litres (88 Gallon)

Engine Kubota D902 3-Cylinder Diesel Engine

HP Pump Type Triplex Plunger Pump

Engine Cooling Water-Cooled

Run Dry Protection Standard

Frost Protection Unloader & Anti-freeze Valve

HP Reel Hydraulic Drive HP Reel

Hose Guidance Not Included (Optional)

Hose Single-wire Lightweight Hose

Reel Arrangement Integrated Filling Reel

Filling Hose 25M Reel

Control Box Ye s

Remote Control Plug and Play Radio Remote

Construction Compact Mild Steel Construction & Powder Coated

Included Accessories 2 Standard Nozzles, User Manual, leader hose

Base Vehicle Suitability Ford Transit Connect, Vauxhall Combo/Vivaro, Mercedes Benz Citan,

VW Caddy/Transporter, Renault Trafic, Peugeot Expert

Warranty 12 Months (terms and conditions apply)

9

2-SERIES OPERATOR’S MANUAL

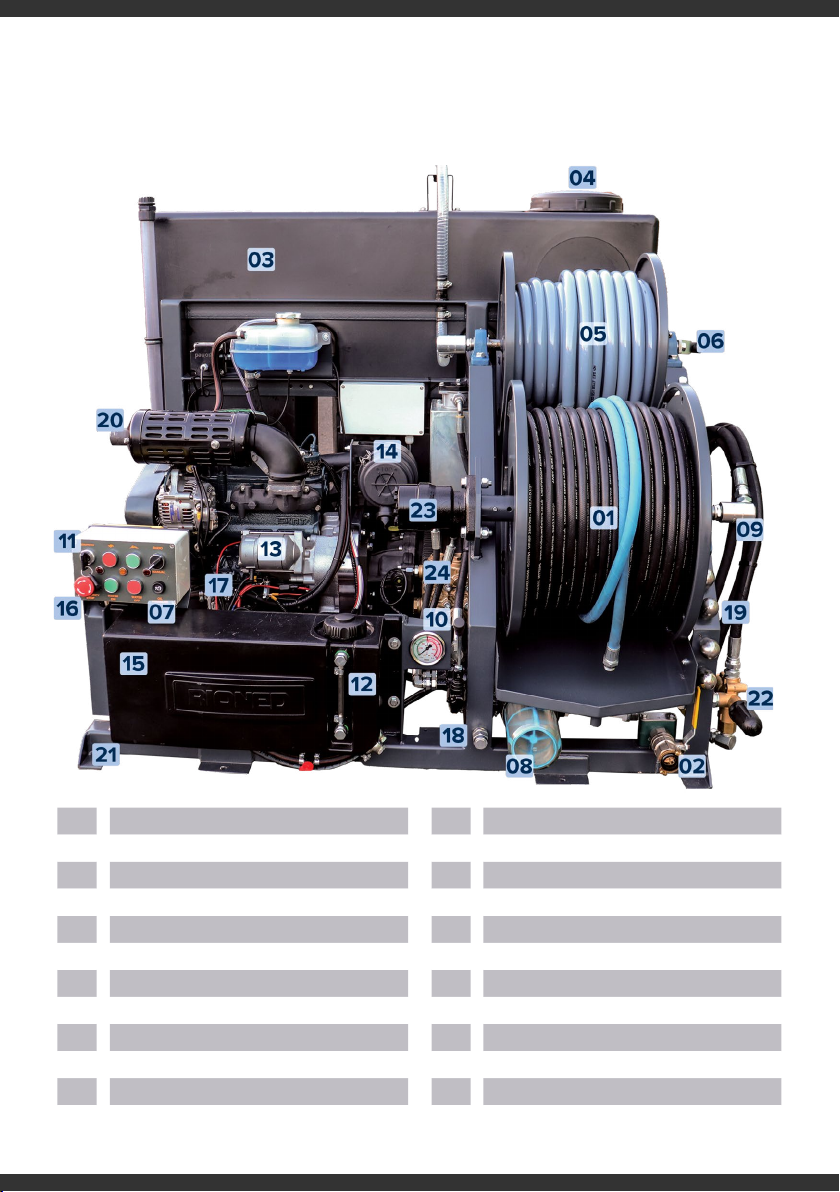

4.0 CONSTRUCTION

2-SERIES

01 High-Pressure Hose Reel 13 Kubota D902 3-Cylinder Diesel Engine

02 Drain and Anti Freeze Filling Point 14 Air Filter

03 Water Tank 15 Fuel Tank

04 Supply Opening Water Tank 16 Emergency Stop

05 Inlet Hose Reel 17 Battery

06 Inlet Hose Reel Handles 18 Engine Oil Drain

07 Control Panel 19 Nozzle Mounts

08 Water Filter 20 Exhaust Manifold

09 Rotary Joint 21 Jetter Mounts

10 Pressure Gauge and 22 Pressure Regulator

11 Ignition Key 23 Hydraulic Hose Reel Motor

12 Fuel Level Indicator 24 Triplex Plunger Pump

10 2-SERIES OPERATOR’S MANUAL

5.1 Before Departure

Before you drive away, check the following:

⊲ Roll the HP-hose neatly and fully onto the hose

reel ensuring no kinks

⊲ Roll the inlet hose neatly and fully onto the

hose reel ensuring no kinks

⊲ Ensure the water tank has been drained to

approximately 10% capacity before driving

5.2 Positioning The Vehicle

When positioning the vehicle please take note of the

following:

⊲ Vehicle engine turned o, vehicle in gear and

hand brake applied

⊲ Always try to site the vehicle on a level, hard

standing surface

⊲ See to it that the vehicle is more or less level.

⊲ If parked on a hill your fuel may run out faster

than usual if the liquid gathers away from the

suction end

⊲ Secure the working area according the local

regulations

⊲ Activate all appropriate hazard and work lights

and beacons

5.3 HP Reel Control

⊲ Always retract the hose slowly to ensure it is

neatly rolled onto the reel, keep hands and

clothing away from the reel to avoid crushing

and always check for contaminants or sharps

that may have lodged onto the reel.

⊲ It is good practice to check the condition of

the hose during retraction and if you suspect

any damage to the hose you should have it

replaced by an authorised agent immediately

5.4 Engine Counter

Some engines are equipped with a visual hours

counter. This indicates the total number of hours that

the engine has been operated and can be used to

determine when the unit is ready for

maintenance and servicing.

5.5 Run Dry Protection

Units are equipped with a run dry switch. When the

tank water level reaches approximately 5-10% the

engine will automatically turn o, furthermore an

override switch can also be added so that in the

event that the run dry switch activates, the operator

may still briefly use the engine to activate other

functions such as the hydraulic reel control or the

anti-freeze suction valve.

5.6 Pre-Operational Checks

You should check the following prior to operation:

⊲ Engine Oil

⊲ Pump Oil

⊲ Fuel Level

⊲ Gear Oil

⊲ Water Level in main tank (maximum recom-

mended water temperature is 60oc / 140of)

⊲ Water filter should be clean and free of debris

⊲ Check nozzle holes and clear debris before

attaching nozzle to the high pressure hose

⊲ Connect the inlet hose to your supply feed and

turn on OR put a supply hose directly into the

water tank by removing the filler cap

5.0 CONTROLS Note: all controls and their operation will be clearly

labelled on all new equipment.

11

2-SERIES OPERATOR’S MANUAL

5.7 Starting The Engine

To start the engine using the electronic control panel,

take the following steps:

1. Ensure you are in a position to operate the

equipment safely

2. Ensure that NO nozzles are attached to the

high-pressure hose.

3. Ensure the emergency stop button is in the

OPEN position

4. Ensure the control switch is set to MANUAL

5. Turn key switch to START position. Release

switch as soon as engine starts

6. Add your selected NOZZLE and feed the hose

into the drain

7. Press the WATER ON button

8. Use the THROTTLE buttons to increase or

decrease the water pressure

5.8 Stopping The Engine

To stop the engine please ensure the following:

1. Reduce engine speed to idle

2. Disengage HP pump fully

3. Turn fuel valve to full closed position (optional).

Turn key switch to OFF position.

5.9 Completion Procedures

At the end of the job, you should:

⊲ Remove nozzle from hose and store on frame

bracket if applicable

⊲ Retract the HP hose and secure

⊲ Retract the inlet hose and secure

⊲ Stop the engine, store any accessories and

drain the water tank down to approximately

5-10% capacity

5.10 Operating the

Equipment

The 2-Series features an Electronic Control Panel

which is easily integrated with an optional Radio

Remote system. The machine can be operated in

two ways, either directly by using the push buttons

on the Electronic Control Panel or via the Radio

Remote handset.

The Electronic Control Panel includes a built-in

throttle, HP Pump ON/OFF and Emergency Stop

button controls.

Standard Operation

1. Throttle UP/DOWN

2. HP Pump ON/OFF

3. Emergency Stop

5.0 CONTROLS: OPERATING THE MACHINE

1

32

12 2-SERIES OPERATOR’S MANUAL

5.11 Using The Radio

Remote Control (Optional)

⊲ If no remote control is fitted switch the control

panel to manual

⊲ If you have a radio remote, ensure the switch is

set to remote

If you have purchased a radio remote control, you

should have had the receiver kit installed to your

nominated vehicle by a qualified professional and

have also received a remote handset. The AG

5-Channel provides the following operations:

Before starting the

engine, switch to “Radio

Remote” on the elec-

tronic control panel

1. Start the jetter by

pressing the START

and ENGINE buttons

simultaneously

2. Throttle UP/DOWN

3. HP Pump ON/OFF

4. Emergency Stop

5. Battery level

indicator

1. Removeable and

rechargeable lithium

battery

2. Safety cut-o strap

5.12 Nozzle Application

The high pressure nozzles are designed to use

pressure to pull the hose through the sewer pipe and

depending on application and nozzle, a degree of

cleaning or unblocking will commence immediately.

All nozzles will have the capability to eject water in

a backwards direction to project them forward and

others will also include forward ejecting water to

assist in the clearance of blockages and debris. The

basic principal can be seen below:

5.13 Using Lances

There are two types of lance:

⊲ Dry Shut

⊲ Safety or Unloader

If you are using a dry shut lance, you should

ensure that you have an unloader valve fitted to

your jetting equipment in lieu of a burst disc

arrangement. The most common cause of burst

disc failure (a manufactured weak spot to protect

from back-pressure) is when using lances. An

unloader valve (or pressure relief valve) is designed

to return water back to the water tank in the event

that the back pressure exceeds the desired level.

1

2

5

4

3

1

2

13

2-SERIES OPERATOR’S MANUAL

A safety lance or unloader lance has the valve

incorporated in its design so that any back

pressure will eject from the lance, normally through

a secondary barrel pointing in the same direction as

the pressurised water.

You should always check that the working

pressure on the lance corresponds with the pressure

of the machine and start the unit on the lowest

pressure setting and when in operation, increase

slowly to the correct working pressure. After use and

when the engine is turned o, activate the trigger to

release pressure from the hose.

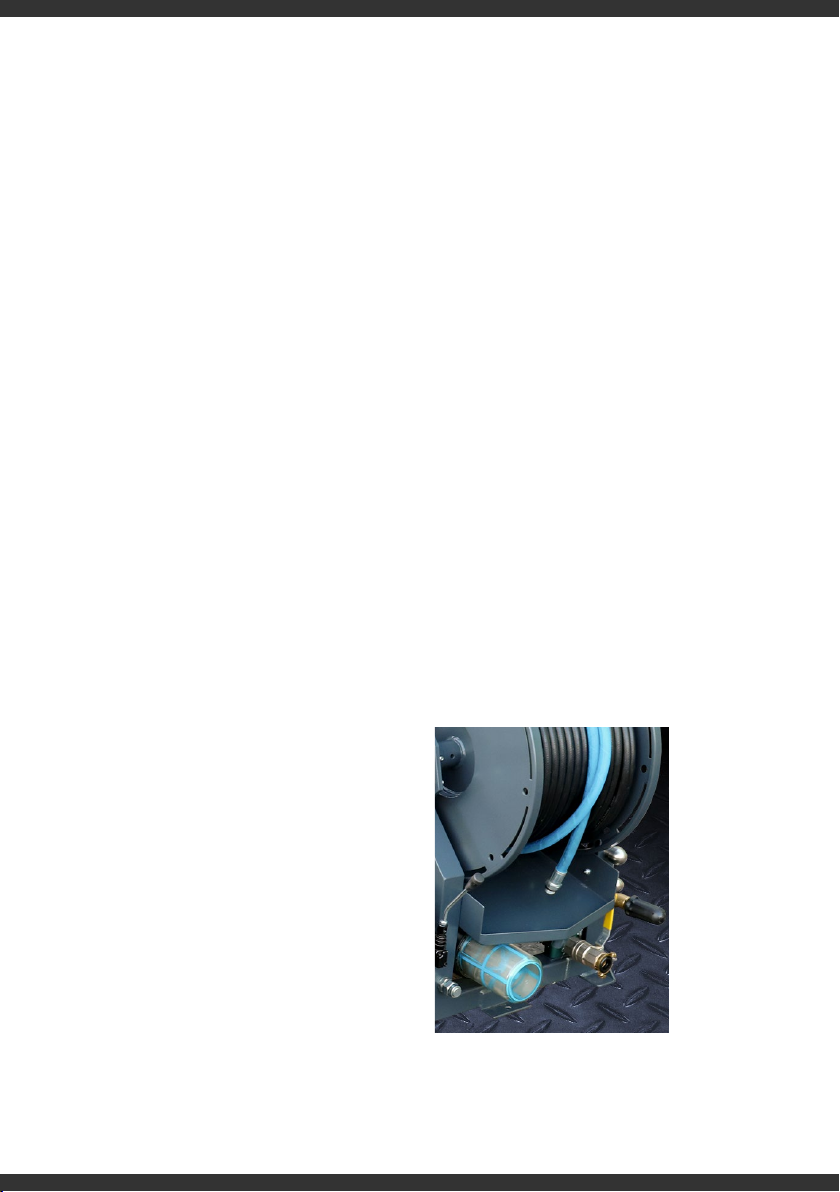

5.14 Frost Protection

It is important to protect your equipment,

particularly the high-pressure pump from freezing as

this can damage your equipment. Damaged caused

to the HP pump by frost is not covered under the

machine warranty. You should never attempt to run

your equipment if you suspect it has frozen. Many

customers will install a night heater for cold weather

periods though all equipment is fitted with an

anti-freeze valve as standard. During cold weather,

perform the anti-freeze procedure at the end of the

day or prior to any long journeys.

The following procedure should be applied:

⊲ Drain water tank

⊲ Turn anti-freeze valve to the open position

(pointing towards the anti-freeze pipe)

⊲ Turn the water tank flow valve to the closed

(vertical) position

⊲ Put anti-freeze hose into the anti-freeze drum

⊲ Turn selector valve to pressure

⊲ Start engine and run until anti-freeze comes out

of high pressure hose (ensure no nozzles are

attached)

⊲ Turn selector valve to dump and turn the

remote briefly onto pressure (remote only)

⊲ Turn remote o and stop engine

***Do not run the equipment with selector in dump

position and remote o or all anti-freeze will be

dumped back into the tank

START-UP

Post anti-freeze > pre-operation

⊲ Refill water tank

⊲ Turn anti-freeze valve and water tank flow valve

(if applicable) back to original operating position

⊲ Put pressure hose into anti-freeze drum

(ensure no nozzles are attached)

⊲ Start engine and run until water starts running

clear or drum has been filled to original level

Obviously the process will have a slight diluting

eect so care must be taken and it is only

designed to reduce the risk of freezing so normal

safety checks should always be conducted.

5.0 CONTROLS

2-Series: Valve position for filling

with anti-freeze

14 2-SERIES OPERATOR’S MANUAL

ACTION FREQUENCY

INITIAL SERVICE After first 50 hours of operation. We recommend that the first

service is through an AG approved Service Centre.

ANNUAL SERVICE We recommend that your jetting machine is serviced

annually by an AG approved Service Centre.

Check oil levels Daily. Recommended oil type usage, below.

Above 25°C (77°F) 10W-30 or 10W-40 or 15W-40

-10 to 25°C (14°F to 77°F) 10W-30 or 10W-40 or 15W-40

Below -10°C (14°F) 10W-30 or 10W-40

Recommended API classification: CF-4, CG-4, CH-4, C1,4

Clean water filter Daily or after high concentration of pollutants

Clean Engine Air Filter Every 100 working hours

Service engine Every 100 working hours or 6 monthly – whichever is soonest

Engine Oil Filter Every 200 working

Lubricate moving parts Every 250 working hours or 6 monthly – whichever is soonest

Cleaning pressure regulator Every 250 working hours or 6 monthly – whichever is soonest

Renew pump oil Every 500 working hours or every 2 years – whichever is

soonest

Check all lines (high pressure/vacuum) including fittings

for leaks.

Drain regulator of accumulated fuel deposits.

Replace spark plugs and set gap.

Have lock-o/filter serviced.

Have combustion deposits removed if using

non-synthetic oil.

Every 500 working hours or every 2 years – whichever is

soonest

Have regulator disassembled, cleaned, and reset.

Have vaporizer disassembled, cleaned, and serviced

Every 1500 working hours

Decalcify suction valves Annually

Decalcify pressure valves Annually

Re-puncture nozzle holes Every 50 working hours

Perform these procedures more frequently under severe, dusty, dirty conditions.

5.15 Recommended Maintenance Schedules

We would recommend the following maintenance plans conducted by a recognised service agent using only

OEM parts.

15

2-SERIES OPERATOR’S MANUAL

6.0 TROUBLESHOOTING

6.1 Troubleshooting Guide

Failure Reason Solution

Engine does not start or

stops abruptly

Machine has run out of fuel Add fuel

Main or secondary fuse blown Contact your service agent

Battery voltage too low Charge or replace

Emergency stop activated Release the emergency stop on machine/

remote

The high-pressure pump

does not produce the

required pressure.

Water tank empty Fill the water tank

Water tank flow valve closed Open the valve

Water filter clogged Stop the machine and clean the water filter

Air in high-pressure pump Allow the machine to run for a few minutes

and if the air doesn’t bleed out contact your

service agent

Suction valves blocked Carefully loosen the valves and descale them

Pump drive belt not suciently tightened Tighten the belt; replace if necessary

Suction valves worn out Contact your service agent

Pressure not consistent

Water level in tank too low Stop the engine, refill the tank and restart

engine

Water supply valve not suciently opened Open the supply valve completely

Water filter clogged Stop the machine and clean the filter

Pump sucks air Stop the machine and check all hoses and

couplings for leakage

Nozzle clogged Stop the machine and clean the nozzle (clean

the nozzle holes)

Pressure valves dirty or worn Stop the machine. Check the condition of the

pressure valves. Clean or replace them

Pump packing is worn out Stop the machine and replace gasket

Pump drive belts slipping Stop the machine and tighten the belts

Pump plungers damaged Contact your service agent

Pressure control clogged or damaged Contact your service agent

16 2-SERIES OPERATOR’S MANUAL

6.2 Useful Links & External References

⊲ kuk.kubota-eu.com/engines/

⊲ www.interpump.co.uk

⊲ www.waterjetting.org.uk

⊲ www.draintraderltd.com

A full range of specialist accessories and nozzles are available from the AG online store or through the parts

department. For information about Andy Guest products, services, parts and accessories visit:

⊲ www.andyguestjetters.co.uk

⊲ Call: +44 (0)3300 240404

Failure Reason Solution

Hydraulic reel does not

wind the hose

Handle not on correct position Put the handle into the correct position

Hydraulic tank almost empty Refill the tank. Check the system for leaks

Working pressure set too low Increase the working pressure, if possible

Return filter for hydraulic tank dirty Switch o the machine and clean the return

filter

Hydraulic system damaged Contact your service agent

Warning lights after short

operation Battery flat / defective

Recharge or replace battery

Check if the unit is charging correctly

Check battery terminals for debris

Electrical supply appears

fine but equipment not

functioning

Emergency stop pushed in Unlock emergency stop

Receiver has no current Check / replace fuses

No radio connection Check functions of control lights

17

2-SERIES OPERATOR’S MANUAL

7.0 SERVICE CENTRES

7.1 Manufacturing Sales + Service

7.2 Service Agents

7.3 Worldwide Agents

We have agents in many countries. Further information on our worldwide

agent network can be found on the website: www.andyguestjetters.co.uk

Andy Guest Jetters Ltd

Unit 11, Riparian Way

The Crossings Business Park

Cross Hills, Keighley

West Yorkshire BD20 7BW

T +44 (0)3300 240404

F +44 (0)1535 636969

www.andyguestjetters.co.uk

Rioned UK Ltd

FreeFlow House

Stephenson Way

Thetford, Norfolk, IP24 3RU

United Kingdom

T +44 (0)3300 240404

F +44 (0) 1638 716863

www.rioned.co.uk

Crumlin Plant Sales Limited

90a Blackisland Road

Craigavon

Portadown BT62 1NH

Tel: 0283 885 2540

HP Pump Services

Wynford Industrial Park

Romsey

Hampshire, SO51 0PW

01794 367 477

Hydro Power UK Ltd

Unit 19d Robell Way

Water Lane Industrial Estate

Storrington (Nr. Pulborough)

West Sussex RH20 3DW

Tel: 01903 741780

Kensway Engineering

Unit 5 Dotton Farm

Sidmouth

Devon EX10 0JY

Tel: 0139 556 7374

Midland Jetting Services Ltd

Unit 4 Kingfisher Ind Estate

Charles Street

West Bromwich

West Midlands B70 0AT

Tel: 0121 520 6641

N1 Jetting Systems Limited

Unit 13 Cathedral Park

Durham DH1 1TF

Tel: 0191 375 7779

Scotjet Limited

50 Loanbank Quadrant

Glasgow

Lanarkshire G51 3HZ

Tel: 0141 440 0200

Technical Camera Services

Drumnacarta, Snugboro

Castlebar, Co. Mayo F23 KW90

Tel: +353 871627963

18 2-SERIES OPERATOR’S MANUAL

8.1 Declarations & Directives

EC Declaration of Conformity for Machinery

(Directive 2006/42/EC, Annex II, sub A) Andy Guest Jetters Ltd

Unit 11, Riparian Way

The Crossings Business Park

Cross Hills

Keighley

West Yorkshire, UK

BD20 7BW

Herewith declares that:

High pressure device model AG 2-SERIES is

⊲ in compliance with the Machinery Directive (2006/42/EC);

⊲ in conformity with the provisions of the following other EEC directives: 2004/108/EC

⊲ and the following harmonised standards have been applied:

NEN-EN-ISO 12100-1, NEN-EN-ISO 12100-2, NEN-EN-ISO 13850,

NEN-EN-ISO 13857, NEN-EN-349, EN 60204-1

Jan Pieters

Managing Director

On Behalf of:

Rioned UK Ltd & Andy Guest Jetters Ltd

8.0 APPENDIX

Jan Pieters

19

2-SERIES OPERATOR’S MANUAL

20 2-SERIES OPERATOR’S MANUAL

www.andyguestjetters.co.uk

Manufacturing

Sales + Service

Service Agents

Andy Guest Jetters Ltd

Unit 11, Riparian Way

The Crossings Business Park

Cross Hills, Keighley

West Yorkshire BD20 7BW

T +44 (0)3300 240404

F +44 (0)1535 636969

www.andyguestjetters.co.uk

Rioned UK Ltd

FreeFlow House

Stephenson Way, Thetford

Norfolk, IP24 3RU

United Kingdom

T +44 (0)3300 240404

F +44 (0) 1638 716863

www.rioned.co.uk

Crumlin Plant Sales Limited

90a Blackisland Road

Craigavon

Portadown BT62 1NH

Tel: 0283 885 2540

HP Pump Services

Wynford Industrial Park

Romsey

Hampshire, SO51 0PW

01794 367 477

Hydro Power UK Ltd

Unit 19d Robell Way

Water Lane Industrial Estate

Storrington (Nr. Pulborough)

West Sussex RH20 3DW

Tel: 01903 741780

Kensway Engineering

Unit 5 Dotton Farm

Sidmouth

Devon EX10 0JY

Tel: 0139 556 7374

Midland Jetting Services Ltd

Unit 4 Kingfisher Ind Estate

Charles Street

West Bromwich

West Midlands B70 0AT

Tel: 0121 520 6641

N1 Jetting Systems Limited

Unit 13 Cathedral Park

Durham DH1 1TF

Tel: 0191 375 7779

Scotjet Limited

50 Loanbank Quadrant

Glasgow

Lanarkshire G51 3HZ

Tel: 0141 440 0200

Technical Camera Services

Drumnacarta, Snugboro

Castlebar, Co. Mayo F23 KW90

Tel: +353 871627963

Table of contents

Other Rioned Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT587908 Operation manual

Siemens

Siemens 8GK6430 - 4KK24 operating instructions

SMC Networks

SMC Networks MGP-XB24 Mounting instructions

Dando

Dando TERRIER Mk 1 Operating and maintenance manual

Greemman

Greemman RECO130F Manual book

thermital

thermital COROLLA PACK 1000 Series Installation, operation and maintenance manual