4 M0412-1 ver 3.0

CONTENTS

1 INTRODUCTION......................................................................................................5

1.1 Installation and Maintenance manual .........................................................................5

1.2 Safety.........................................................................................................................6

1.2.1 General...............................................................................................................................6

1.2.2 Explanation of warnings .....................................................................................................6

1.3 Tightening torques......................................................................................................7

1.4 Recommended equipment .........................................................................................7

1.5 Required products......................................................................................................7

2 INSTALLATION.......................................................................................................8

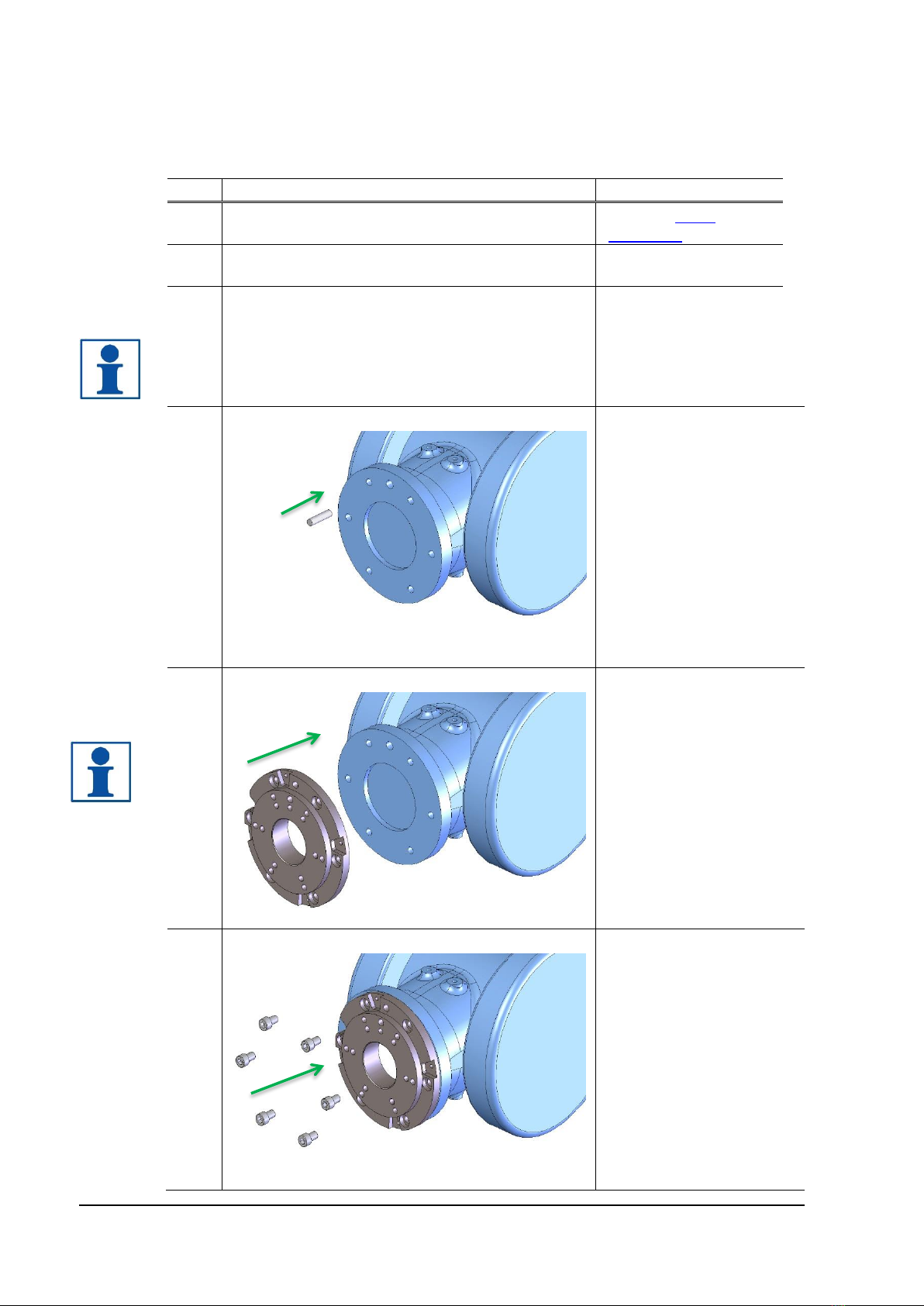

2.1 Installation of swivel tool changer on robot.................................................................8

2.2 Installation of tool attachment on tool .......................................................................11

2.3 Manual unlocking of swivel tool changer ..................................................................13

3 MAINTENANCE AND SERVICE............................................................................14

3.3 Maintenance scheme ...............................................................................................14

3.3.1 Every second week ..........................................................................................................14

3.3.2 Every six-months or 250,000 tool changes......................................................................14

3.3.3 To replace when damaged or worn-out ...........................................................................15

3.3.4 Complete service of swivel tool changer..........................................................................15

3.4 Specification of maintenance activities.....................................................................16

3.4.1 Visual inspection of swivel tool changer...........................................................................16

3.4.2 Visual inspection and cleaning of tool attachment ...........................................................17

3.4.3 Cleaning and lubrication of swivel tool changer...............................................................18

3.4.4 Cleaning and lubrication of tool attachment.....................................................................19

4 DISMOUNTING AND REPLACEMENT.................................................................20

4.1 Replacement of swivel tool changer.........................................................................20

4.2 Replacement of tool attachment...............................................................................22

4.3 Replacement of wear parts.......................................................................................23

4.3.1 Replacement of air sealings.............................................................................................23

4.3.2 Replacement of signal pins ..............................................................................................24

4.3.3 Replacement of O-ring .....................................................................................................25

5 DISPOSAL AND RECYCLING ..............................................................................26